Preparation method of nanostructured polypyrrole

A technology of nanostructure and polypyrrole, which is applied in nanotechnology, electrical components, electrolytic capacitors, etc., can solve the problems of limiting polypyrrole nanostructure, product purity and structural influence, and achieves simple and fast methods, good environmental stability, and reaction Process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

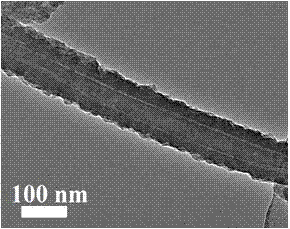

[0032] The present invention provides a method for preparing polypyrrole with a nanostructure. In one embodiment, it includes the steps of: using manganese dioxide with a certain nanostructure morphology as a reaction template to react with pyrrole monomers in an acidic solution , the pH of the acidic solution is 0~6, the reaction temperature is -10~50°C, the molar ratio of pyrrole monomer to manganese dioxide is ≥1:2, and polypyrrole is prepared, and the nanostructure of polypyrrole is in the form of The appearance is the same as the nanostructure appearance of the manganese dioxide.

[0033] In some other preferred embodiments, at least one of the following conditions may also be preferred:

[0034] The pH value of the acidic solution is 0-3.

[0035] The reaction temperature is 0-15°C.

[0036] The molar ratio of the pyrrole monomer to manganese dioxide is 1:2 to 1:1, more preferably 1:1.

[0037] The structure and morphology of the manganese dioxide is a one-dimensional...

Embodiment 1

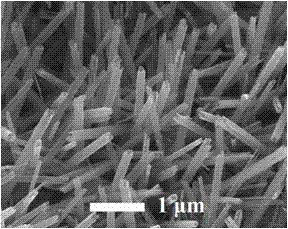

[0045] Weigh 0.658 g of potassium permanganate powder and dissolve it in 75 ml of deionized water to form a purple solution, then add 1.5 ml of concentrated hydrochloric acid, stir evenly by magnetic force, place it in a hydrothermal reaction kettle, and keep it warm at a temperature of 140°C Natural cooling after 10 hours, the α-type manganese dioxide nanotube powder obtained, its scanning electron microscope picture is as follows Figure 1a As shown, after filtering and rinsing, bake in a drying oven at 80°C for 12h.

[0046] Prepare 20ml of dilute hydrochloric acid solution and adjust the solution to pH=1, weigh 0.1 g of the above-mentioned manganese dioxide powder into dilute hydrochloric acid, and make the dioxide Manganese is fully dispersed in the solution, forming a brown suspension.

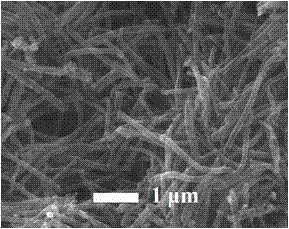

[0047]Quickly inject 75 μl of pyrrole monomer into the above-mentioned suspension using a micro-injection pump, stir with magnetic force for 15 minutes to mix the reactants evenly, and t...

Embodiment 2

[0049] Potassium permanganate and manganese sulfate were weighed and dissolved in deionized water at a molar ratio of 2:3, and the two solutions were uniformly mixed, and stirred magnetically at 60°C for 6 hours to react to obtain α-type manganese dioxide nanorod powder. After filtering and rinsing, bake in a drying oven at 80°C for 12 hours.

[0050] Prepare 15ml of dilute sulfuric acid solution and adjust the solution to pH = 2, weigh 0.05 g of the above manganese dioxide powder into dilute sulfuric acid, and ultrasonically disperse the manganese dioxide in the solution for 30 minutes to form a brown suspension liquid.

[0051] Quickly inject 50 μl of pyrrole monomer into the above-mentioned suspension using a micro-injection pump, stir the reactants uniformly for 20 minutes by magnetic stirring, and let stand at 5°C for 1.5 hours to obtain a black suspension. After filtering, Wash with deionized water and absolute ethanol several times until pH = 7, and then dry in a vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com