Method for modifying polyester fabric by using magnetic nano iron trioxide

A technology of ferric oxide and polyester fabrics, applied in physical treatment, textiles and papermaking, fiber types, etc., can solve problems such as uneven dispersion of nanoparticles, influence of nanomaterial properties, poor washing fastness of fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

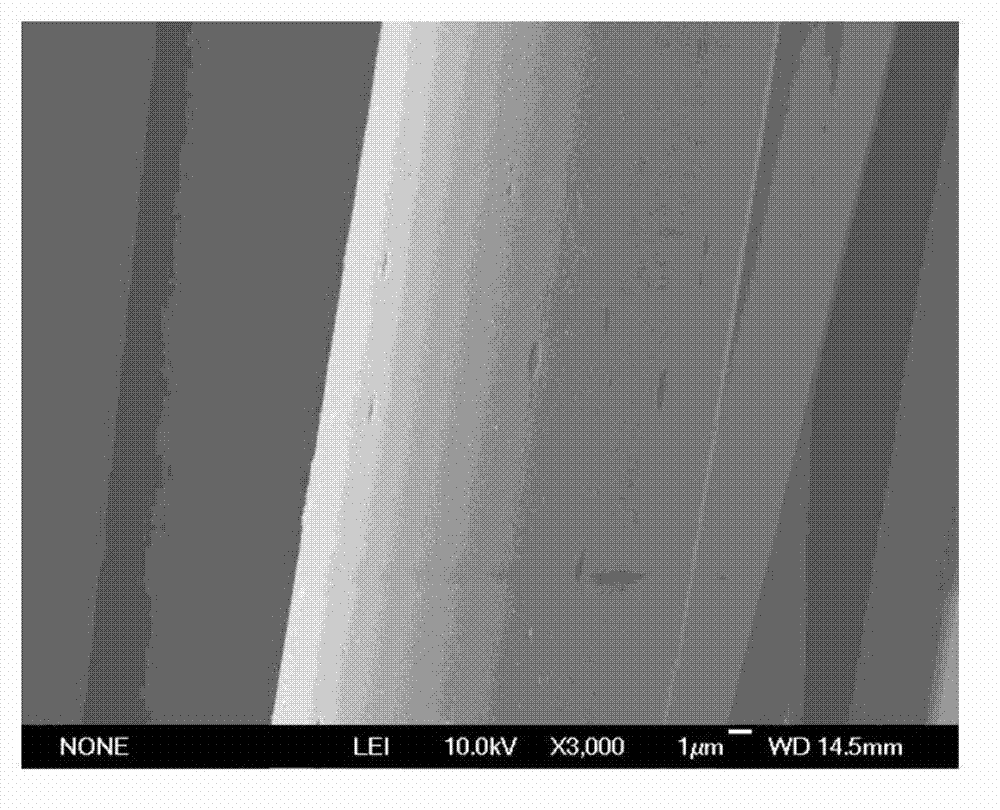

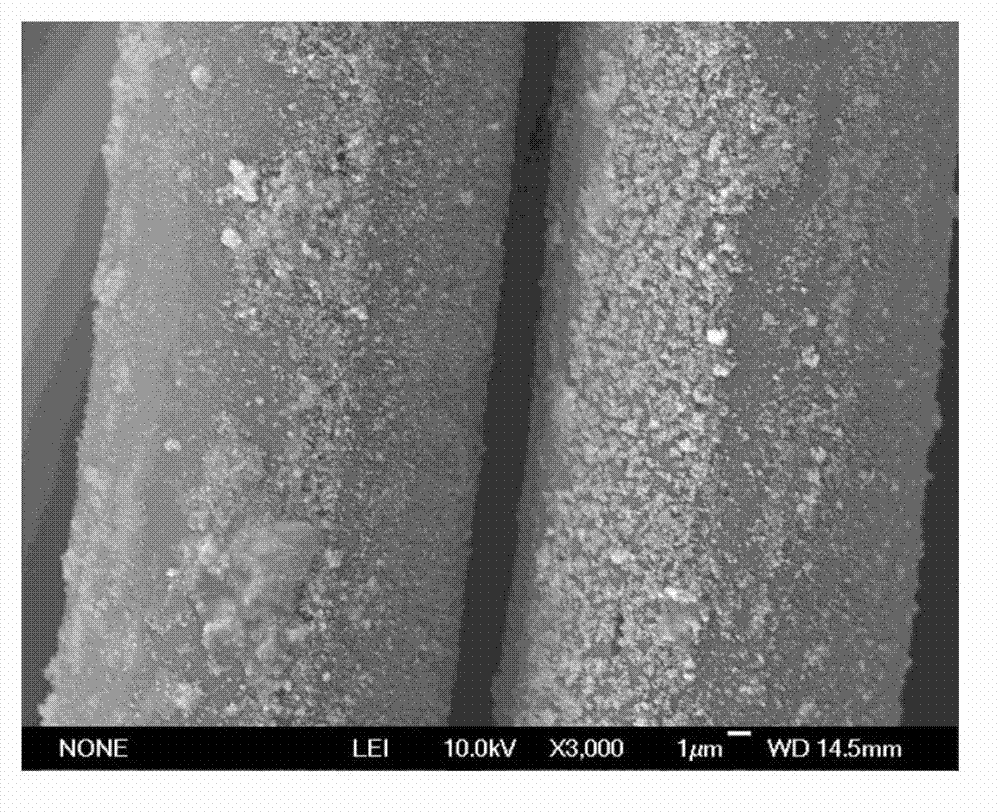

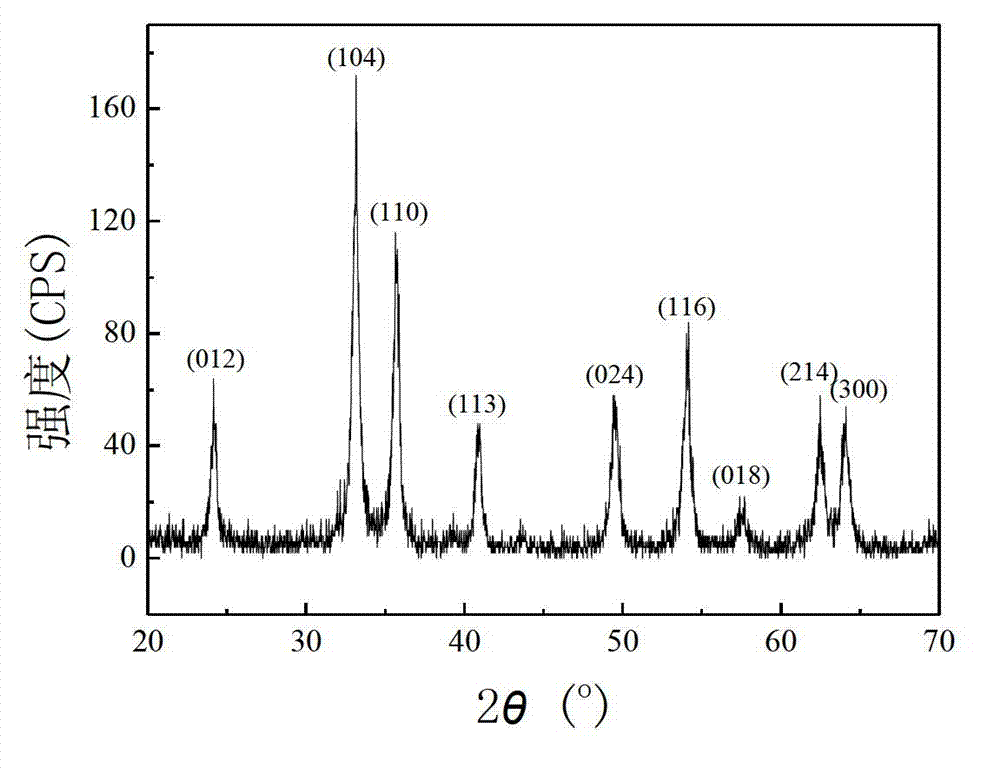

[0068] Take 5g polyester fabric, weigh 160g sodium hydroxide according to the quality of polyester fabric, measure 1L deionized water, dissolve 160g sodium hydroxide in 1L deionized water to prepare sodium hydroxide with a mass volume percentage concentration of 160g / L solution, put 5g of polyester fabric into the prepared sodium hydroxide solution, pretreat the polyester fabric with sodium hydroxide solution for 20 minutes at 80°C, and then take it out to obtain the pretreated polyester fabric. Wash the polyester fabric with acetone, absolute ethanol and deionized water respectively, place the cleaned pretreated polyester fabric at 80°C for 15 minutes, and dry the pretreated polyester fabric;

[0069] Weigh ferric nitrate and oxalic acid respectively, measure 700mL deionized water, fully dissolve the weighed ferric nitrate and oxalic acid in the measured deionized water to obtain a mixed solution of ferric nitrate and oxalic acid, and ferric nitrate in a mixed solution of ferric...

Embodiment 2

[0073] Weigh 10g of polyester fabric, weigh 200g of sodium hydroxide according to the quality of polyester fabric, measure 1L of deionized water, dissolve 200g of sodium hydroxide in 1L of deionized water to prepare sodium hydroxide with a mass volume percentage concentration of 200g / L solution, put 10g of polyester fabric into the prepared sodium hydroxide solution, pretreat the polyester fabric with sodium hydroxide solution for 30 minutes at 90°C, and then take it out to obtain the pretreated polyester fabric. Wash the polyester fabric with acetone, absolute ethanol and deionized water respectively, place the cleaned pretreated polyester fabric at 90°C for 15 minutes, and dry the pretreated polyester fabric;

[0074] Weigh ferric nitrate and oxalic acid respectively, measure 900mL deionized water, fully dissolve the weighed ferric nitrate and oxalic acid in the measured deionized water to obtain a mixed solution of ferric nitrate and oxalic acid, and ferric nitrate in a mixe...

Embodiment 3

[0078] Take 8g polyester fabric, weigh 180g sodium hydroxide according to the quality of polyester fabric, measure 1L deionized water, dissolve 180g sodium hydroxide in 1L deionized water to prepare sodium hydroxide with a mass volume percentage concentration of 180g / L solution, put 8g of polyester fabric into the prepared sodium hydroxide solution, and pretreat the polyester fabric with sodium hydroxide solution for 30 minutes at 100°C, and then take it out to obtain the pretreated polyester fabric. Wash the polyester fabric with acetone, absolute ethanol and deionized water respectively, place the cleaned pretreated polyester fabric at 85°C for 20 minutes, and dry the pretreated polyester fabric;

[0079] Weigh ferric nitrate and oxalic acid respectively, measure 800mL deionized water, fully dissolve the weighed ferric nitrate and oxalic acid in the measured deionized water to obtain a mixed solution of ferric nitrate and oxalic acid, and ferric nitrate in a mixed solution of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com