Double-component low-hardness high-heat-conductivity room-temperature-curing organosilicon heat conducting adhesive

A room-temperature curing, low-hardness technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of high hardness of thermally conductive adhesives, increased interface thermal resistance, and affecting heat dissipation effects, etc., to achieve excellent Thermal conductivity, thermal conductivity unchanged, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

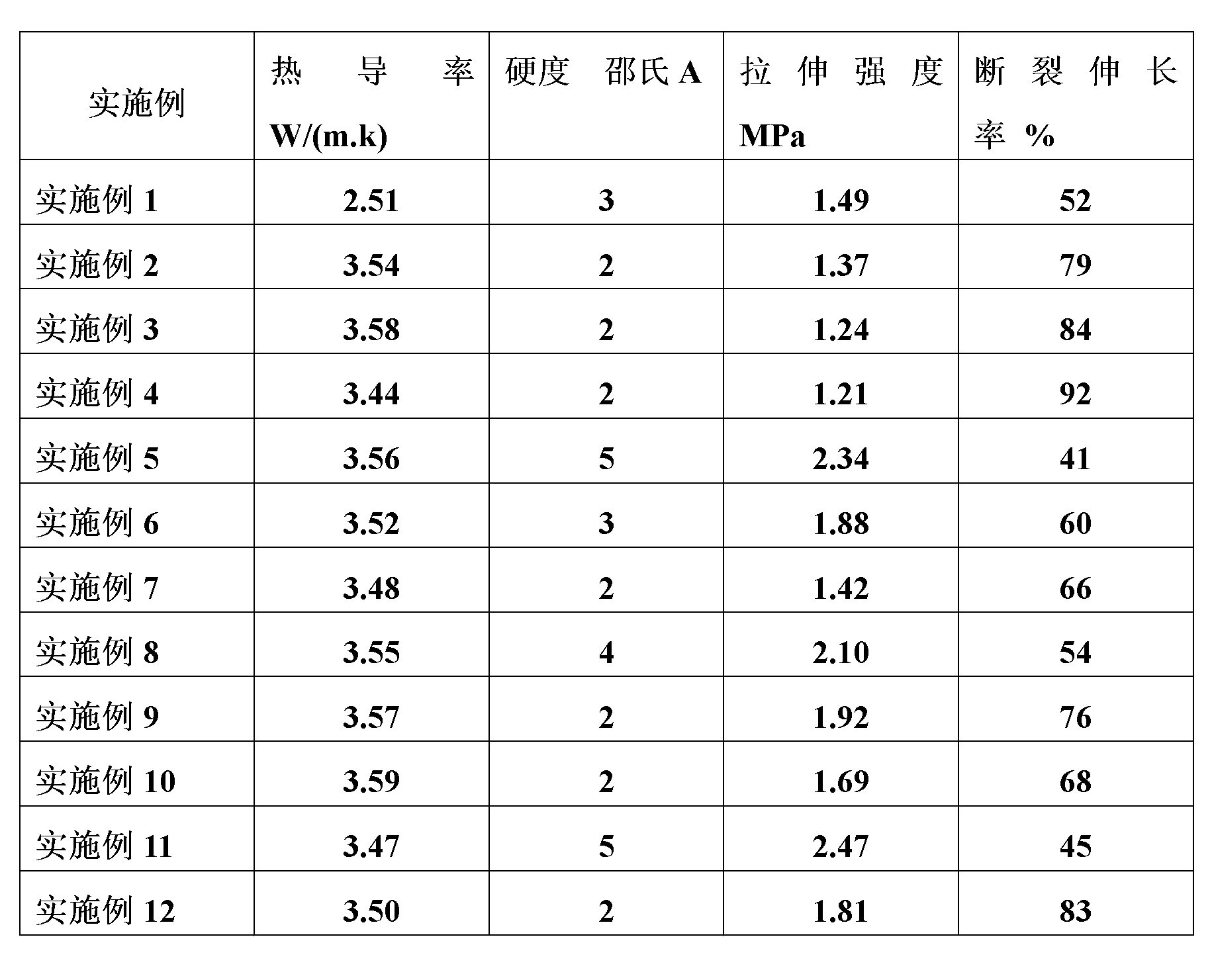

Examples

Embodiment 1

[0021] Component A is composed of a base material and a chloroplatinic acid catalyst (also known as a chloroplatinum catalyst) with a pure platinum content of 2000ppm (also known as a chloroplatinum catalyst) in a weight ratio of 100:0.5, while component B is composed of a base material, terminal hydrogen-containing silicone oil, and side hydrogen-containing The silicone oil and the inhibitor are mixed according to the weight ratio of 100:8:5:0.8. When used, the A component and the B component are mixed and used in a weight ratio of 1:1.

[0022] The aforementioned base material is a base material obtained by mixing 100 g of divinyl silicone oil and 1200 g of alumina, treating with 10 g of hexamethyldisilazane at 120° C., and then cooling to room temperature.

[0023] Among them: the above-mentioned divinyl silicone oil refers to the divinyl silicone oil with a vinyl content of 0.2% in the molecule and a viscosity of 100 Pa.S; alumina is alumina with a particle size of 2 to 30 ...

Embodiment 2

[0025] Component A is composed of base material and chloroplatinic acid catalyst with a pure platinum content of 8000ppm in parts by weight ratio of 100:0.1, while component B is composed of base material, hydrogen-containing silicone oil at the end, hydrogen-containing silicone oil at the side and inhibitor in parts by weight Ratio 100: 8:0.5:0.1 mixed composition.

[0026] The aforementioned base material is a base material obtained by mixing 100 g of divinyl silicone oil and 1300 g of alumina, treating with 10 g of hexamethyldisilazane at 115° C., and then cooling to room temperature. All the other are the same as the description of embodiment 1.

Embodiment 3

[0028] Component A is composed of base material and chloroplatinic acid catalyst with a pure platinum content of 3000ppm in parts by weight ratio of 100:0.3, while component B is composed of base material, hydrogen-containing silicone oil at the end, hydrogen-containing silicone oil at the side and inhibitor in parts by weight The ratio is 100:10:0.1:0.7 mixed composition.

[0029] The aforementioned base material is a base material obtained by mixing 100 g of divinyl silicone oil and 1500 g of alumina, treating with 10 g of hexamethyldisilazane at 120° C., and then cooling to room temperature. All the other are the same as the description of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com