Electrochemical preparation and applications of rare earth coordination polymer film

A technology of coordination polymers and films, applied in electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of difficult to obtain molecular dispersion, unfavorable performance of rare earth complex fluorescent probes, and complex agglomeration. , to achieve the effect of simple operation, convenient and quick measurement, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] New compound: preparation and crystal structure characterization of europium biquinoline dicarboxylic acid coordination polymer (I).

[0049] (1) 0.039g 2,2'-biquinoline-4,4'-dicarboxylic acid (H 2 BQDC) was dissolved in 10mL of DMF to obtain solution A;

[0050] (2) 0.026g EuC1 3 ·6H 2 O was dissolved in 10mL DMF to obtain solution B;

[0051] (3) Solution A and solution B were mixed, and the resulting mixture was transferred to an autoclave, and reacted for 3 days under solvothermal conditions at 80° C., filtered after natural cooling, and washed twice with 3 mL DMF to obtain light yellow compound I, The yield was 79%.

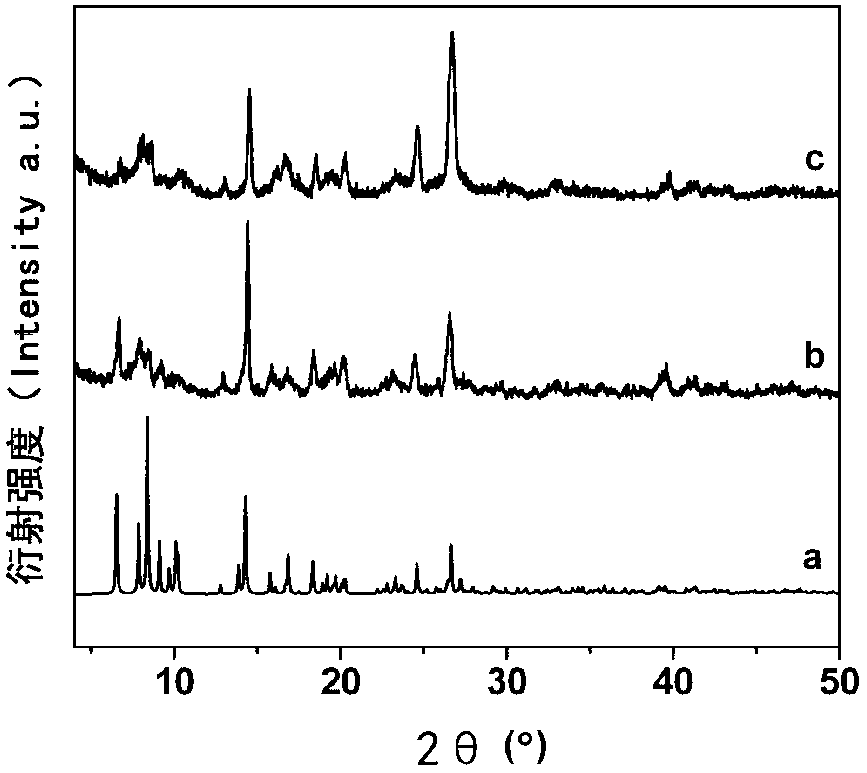

[0052] Single crystal structure analysis shows that the compound is triclinic, P-1 space group, α=11.122(1), b=11.938(1), α=74.869(2), β=76.480(2), γ=73.859(2)°, Z=2, its molecular formula is {[Eu 2 (BQDC) 3 (DMF) 3 (H 2 O)]·0.5DMF·H 2 O} n (I). Rare earth coordination polymer I has a two-dimensional layered structure, and adjacent tw...

Embodiment 2

[0066] Film preparation route 2: a method for preparing a terbium terephthalic acid coordination polymer (II) film, comprising the following steps:

[0067] (1) Preparation of electrolyte: Tb(NO 3 ) 3 0.010M, terephthalic acid (H 2 BDC) 0.015M and NH 4 NO 3 0.050M, the solvent is a mixed solvent of DMF and water (volume ratio is 100:1);

[0068] (2) Use graphite rod as auxiliary electrode (anode), FTO glass as working electrode (cathode), constant current 0.20mA / cm 2 , electrolysis time 20min;

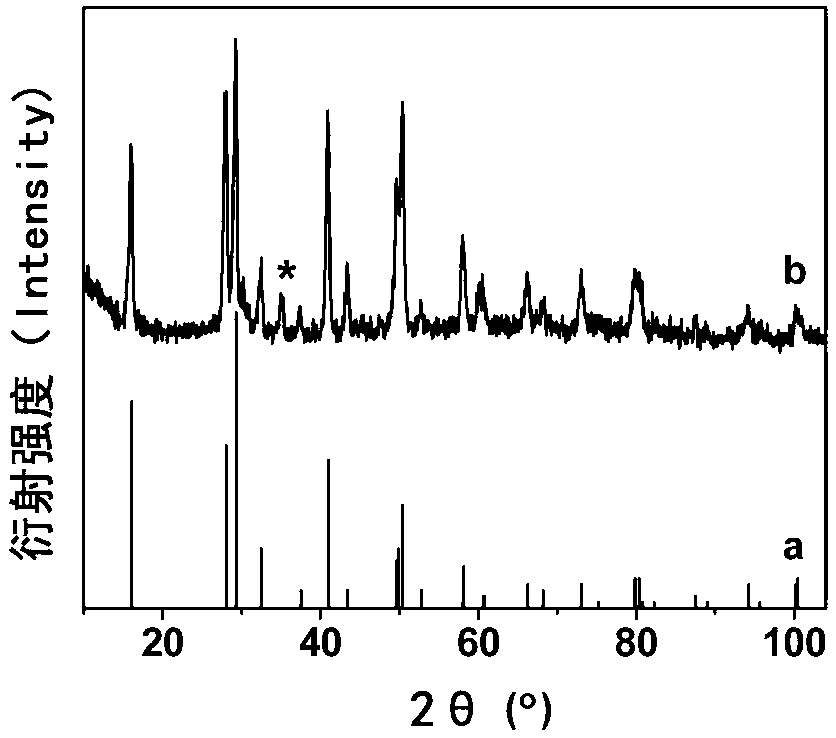

[0069] (3) After the electrolysis, a white, dense film is uniformly deposited on the surface of the FTO glass. Its powder diffraction pattern and [Tb 2 (BDC) 3 4H 2 Powder Diffraction of O]n(II) Single Crystal Simulation Figure 1 To (if Figure 9 , refer to: J.Am.Chem.Soc.1999, 121, 1651-1657), confirmed that the prepared thin film is rare earth coordination polymer II thin film, the microscopic morphology of this thin film is shown in Figure 10 .

Embodiment 3

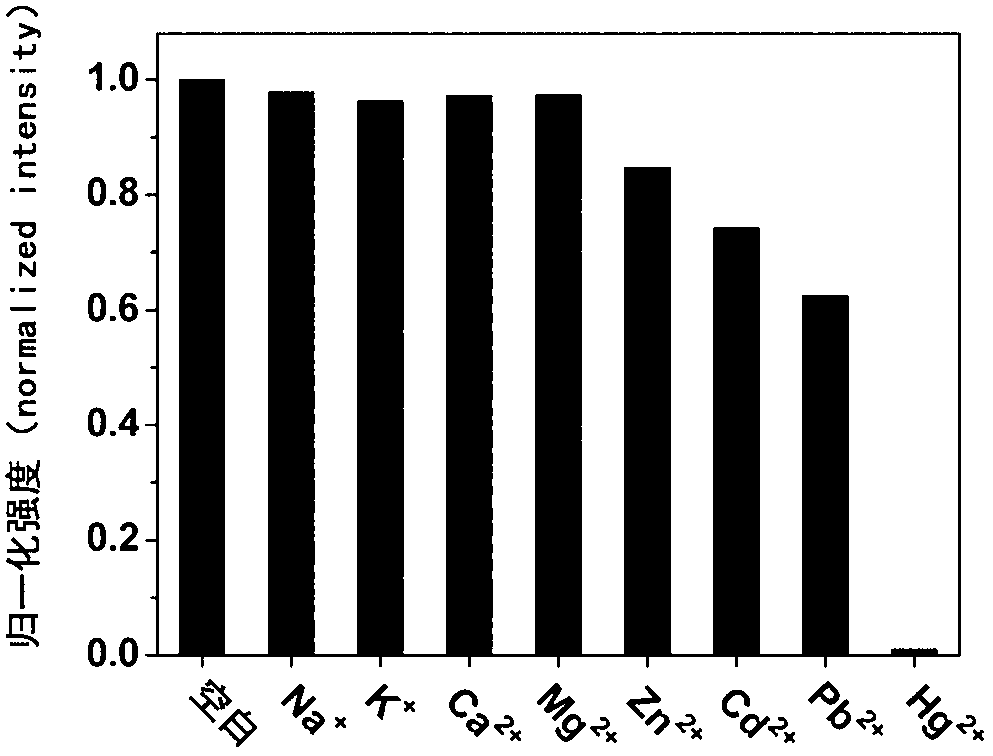

[0071] Applications of Rare Earth Coordination Polymer Films:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com