Bacteria cellulose hemodialysis membrane

A technology of bacterial cellulose and hemodialysis, which is applied in the field of hemodialysis membranes, can solve the problems affecting the accuracy and reliability of the test data of the mechanical properties of the membrane, uneven microstructure of the regenerated membrane, rough process, etc., and achieve excellent mechanical strength, excellent Biocompatibility, fast dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

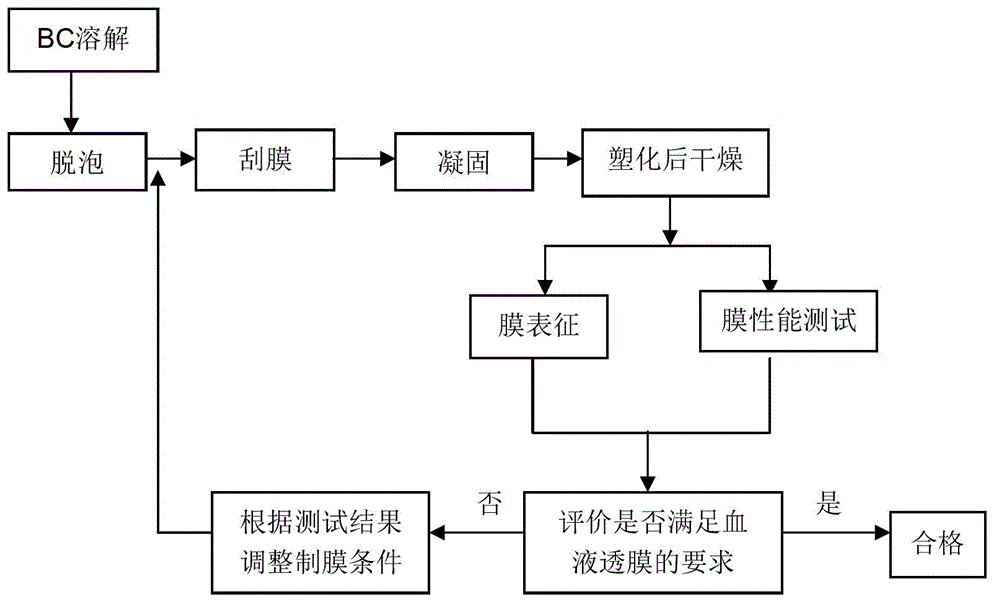

[0041] combine figure 1 , prepare bacterial cellulose membrane hemodialysis membrane of the present invention, comprise the following steps:

[0042] The first step, bacterial cellulose pretreatment: take a certain amount of bacterial cellulose powder and pass through a 150-mesh sieve, soak the sieved powder in 3% NaOH solution, stir at room temperature for 3 hours, vacuum filter, and use Repeatedly wash with deionized water until the washing liquid is neutral, then soak it in absolute ethanol for 3 times, keep for 3 hours each time, and finally put it into a vacuum drying oven for drying at a drying temperature of 80°C until the powder has a constant weight;

[0043] The second step, the preparation of LiCl / DMAC dissolution system: put a certain mass of analytically pure LiCl particles into a blast drying oven, dry at 80°C for 24 hours, and mix the dried LiCl powder with a certain amount of DMAC solvent And stirred at room temperature, prepared into a LiCl / DMAC solution with...

Embodiment 2

[0053] combine figure 1 , prepare bacterial cellulose membrane hemodialysis membrane of the present invention, comprise the following steps:

[0054] The first step, bacterial cellulose pretreatment: take a certain amount of bacterial cellulose powder and pass through a 150-mesh sieve, soak the sieved powder in 6% NaOH solution, stir at room temperature for 3 hours, vacuum filter, and use Repeated washing with deionized water until the washing solution is neutral, then soaking in absolute ethanol for 4 times, each time for 3 hours, and finally put it into a vacuum drying oven for drying at a drying temperature of 80°C until the powder has a constant weight;

[0055] The second step, the preparation of LiCl / DMAC solution system: put a certain mass of analytically pure LiCl particles into a blast drying oven, dry at 110°C for 24 hours, and mix the dried LiCl powder with a certain amount of DMAC solvent and stirred at room temperature, and prepared into a LiCl / DMAC solution with...

Embodiment 3

[0065] combine figure 1 , prepare bacterial cellulose membrane hemodialysis membrane of the present invention, comprise the following steps:

[0066] The first step, bacterial cellulose pretreatment: take a certain amount of bacterial cellulose powder and pass through a 150-mesh sieve, soak the sieved powder in 6% NaOH solution, stir at room temperature for 3 hours, vacuum filter, and use Wash with deionized water repeatedly until the washing liquid is neutral, then soak in absolute ethanol for 5 times, each time for 3 hours, and finally put it into a vacuum drying oven for drying at a drying temperature of 80°C until the powder has a constant weight;

[0067] The second step, the preparation of LiCl / DMAC solution system: put a certain mass of analytically pure LiCl particles into a blast drying oven, dry at 130°C for 24 hours, and mix the dried LiCl powder with a certain amount of DMAC solvent And stirred at room temperature, prepared into a LiCl / DMAC solution with a concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com