Amphoteric electrolyte-modified hybrid silica gel material and solid-phase extraction method thereof

An amphoteric electrolyte, hybrid silica gel technology, applied in organic chemistry methods, chemical instruments and methods, zwitterion exchange, etc., to achieve high recovery, fast adsorption and desorption, and improved speed and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

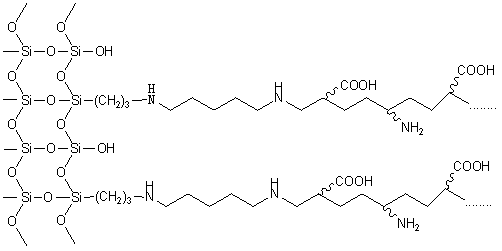

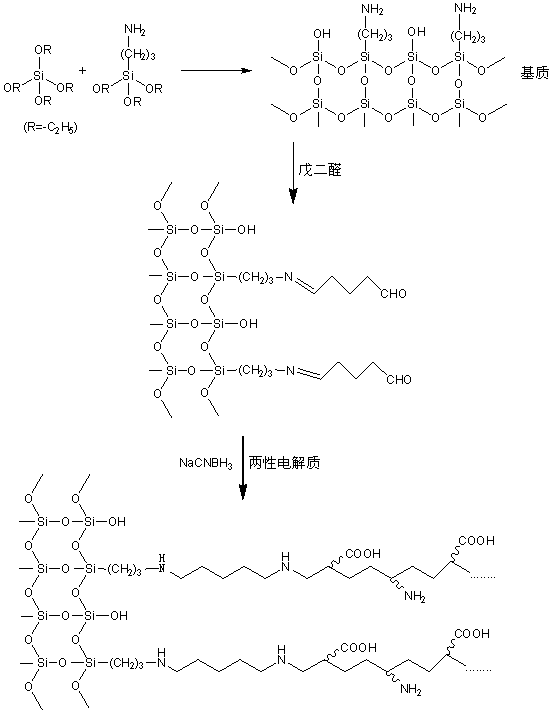

[0028] The synthetic route for the preparation of ampholyte-modified hybrid silica materials is as follows figure 1 As shown, tetraethoxysilane (TEOS) and aminopropyltriethoxysilane (APTES) were used as precursor molecules, cetyltrimethylammonium bromide (CTAB) was used as template agent, and absolute ethanol As a solvent, a hybrid silica material with amine groups on the surface was prepared by sol-gel method ( figure 1 ). The amine group of the hybrid silica gel material reacts with the excess aldehyde group of glutaraldehyde under the condition of pH 8.0 to form C=N, so that the surface of the hybrid silica gel is bonded to the aldehyde group, and the same method is applied to the Under the condition of pH 8.0, the aldehyde group at the other end of the glutaraldehyde bonded to the hybrid silica material reacts with the amine group of the excess ampholyte to form C=N, which is unstable and requires NaCNBH 3 Reduction of C=N to stable C-N ( figure 1 ).

[0029] The speci...

Embodiment 2

[0032] Weigh 50 mg of the ampholyte-modified hybrid silica gel material prepared in Example 1, put it into a 3mL column tube with a lower sieve plate with a pore diameter of 5 μm, fill it into an upper sieve plate with a pore diameter of 20 μm, shake it evenly with a vibrating bed, press the column Machine compaction.

Embodiment 3

[0034] The quartz capillary was sequentially passed through concentrated HNO 3(10min), distilled water, HF (10min), distilled water, 1mol / L NaOH (12h), distilled water, 0.1mol / L HCl (1h), distilled water, methanol after treatment, put the quartz capillary column in the gas chromatography furnace, 120°C N 2 Dry under flow for 3 h, add 112 μL tetraethoxysilane (TEOS), 118 μL aminopropyltriethoxysilane (APTES), 215 μL absolute ethanol, 32 μL water, and 8 mg cetyltrimethylammonium bromide (CTAB) After fully mixing, introduce it into the pretreated quartz capillary via a syringe, seal both ends with silicone rubber, heat at 40°C for reaction polymerization for 24 hours, and rinse the polymerized material with ethanol through a constant flow syringe pump to remove CTAB (30min ), then washed with water and 100mmol / L phosphate (pH 8.0) respectively, and then continuously pumped 100mmol / L phosphate (pH 8.0) containing 10% glutaraldehyde, reacted at 90°C for 0.5h, and washed with phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com