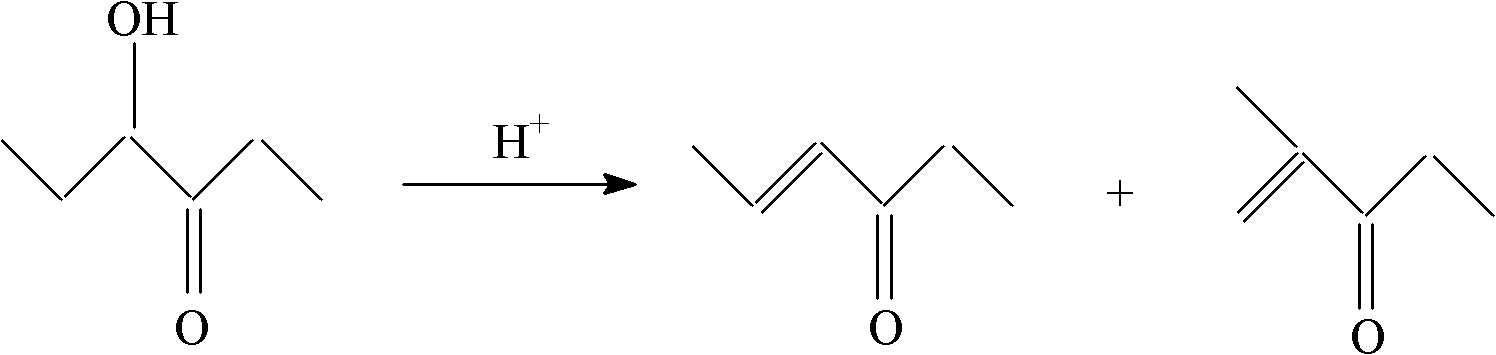

Method for preparing 4-hexene-3-ketone by 4-hydroxy-3-hexanone dehydration

A technology of hexanone and hydroxyl, applied in the field of preparing 4-hexen-3-one, can solve the problems of poor catalyst activity, low space velocity, high reaction temperature, etc., achieve high specific surface area, developed pore structure, and avoid molding steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

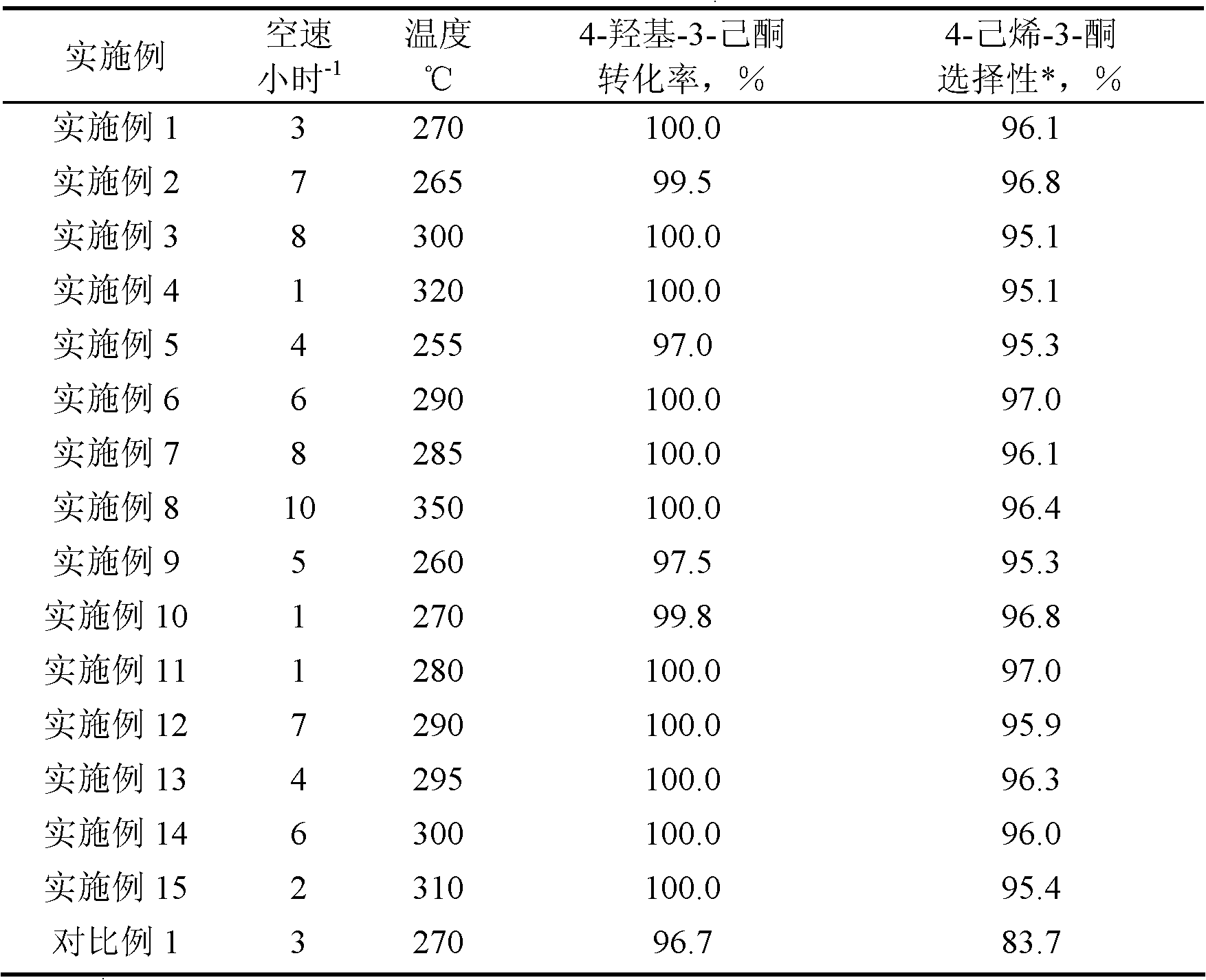

Examples

Embodiment 1

[0020] Weigh 4 grams of 1 mol / liter nitric acid solution and 5 grams of water, add 1 gram of polyoxyethylene-polyoxypropylene-polyoxyethylene (molecular weight 5800, referred to as P123), stir and dissolve at room temperature, and add polyethylene oxide to the mixed solution. Diol (molecular weight 10000) 0.7 grams and 1.26 grams of aluminum nitrate (Al(NO 3 ) 3 9H 2 0), after stirring evenly, transfer to the ice-water mixing bath and continue to stir for 5 minutes. 5.1 g of tetramethyl orthosilicate was added to the mixed solution, and vigorously stirred for 20 minutes. Pour the mixture into a mold to seal it, and place it in an oven at 60°C for 72 hours of aging. After taking it out, it was demoulded, dried at 25°C, and finally fired at 600°C for 8 hours to obtain a monolithic silicon-aluminum oxide material with a silicon-aluminum molar ratio Si / Al=16. The mass ratio of each component is: R1 / SiO 2 =0.35, R2 / SiO 2 =0.5,H 2 O / SiO 2 =4.5,H + / SiO 2 =0.13, Al 2 o 3 ...

Embodiment 2

[0023] Weigh 12 grams of 0.3 mol / liter phosphoric acid solution, add 4.0 grams of polyoxyethylene-polyoxypropylene-polyoxyethylene (molecular weight 1500), stir and dissolve at room temperature, add polyethylene glycol (molecular weight 10000) 0.6 After stirring evenly, the mixed solution was added to the isopropanol solution containing 8.9 grams of tetrapropyl orthosilicate and 0.14 grams of aluminum isopropoxide, and vigorously stirred for 20 minutes. Pour the mixture into a mold and seal it, and place it in an oven at 80°C for 72 hours of aging. After taking it out, it was demolded, dried at room temperature, and finally baked at 550° C. for 5 hours to obtain a monolithic silicon-aluminum oxide material with a silicon-aluminum molar ratio Si / Al=75. The pore structure of the product is similar to the product of [Example 1]. The mass ratio of each component is: R1 / SiO 2 =0.3, R2 / SiO 2 = 2.0, H 2 O / SiO 2 =6,H + / SiO 2 =0.18, Al 2 o 3 / SiO 2 = 0.017. The specific sur...

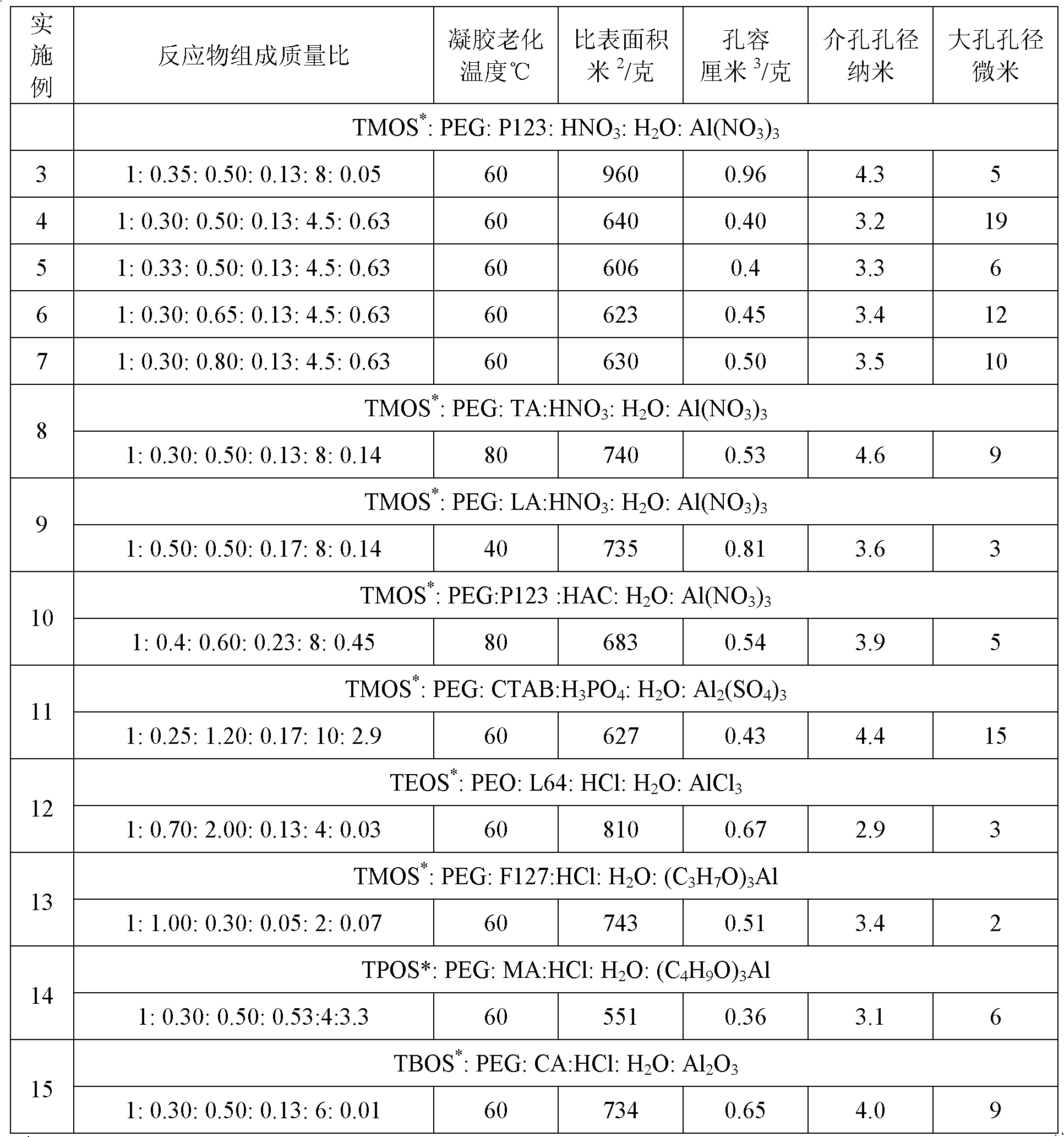

Embodiment 3~15

[0026] According to the various steps and conditions of [Example 1], the silicon-aluminum oxide material is obtained, but the silicon source (tetramethyl orthosilicate TMOS, tetraethyl orthosilicate TEOS, tetrapropyl orthosilicate TPOS, orthosilicate) is changed. tetrabutyl silicate (TBOS), aluminum source (aluminum nitrate, aluminum sulfate, aluminum chloride, aluminum isopropoxide, aluminum isobutoxide and pseudoboehmite Al 2 o 3 ), the type of phase separation inducer R1 (polyethylene glycol PEG, polyoxyethylene PEO) or structure directing agent R2 (polyoxyethylene-polyoxypropylene-polyoxyethylene (molecular weight 12000, F127), polyoxyethylene-polyoxyethylene Oxypropylene-polyoxyethylene (molecular weight 2900, L64), cetyl trimethyl ammonium bromide CTAB, citric acid CA, lactic acid LA, tartaric acid TA, malic acid MA), raw material ratio, gel aging temperature and other parameters , specifically listed in Table 1. Characterization of the synthesized product shows that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com