Method for reducing dissolved loss of water-soluble vitamins in aquatic expanded feed

A technology for water-soluble vitamins and extruded feed, which is applied in animal feed, animal feed, application, etc., can solve the problems of water-soluble component dissolution, failure to fundamentally solve the problem, increase in cost, etc., and achieve the effect of stabilizing the interface film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

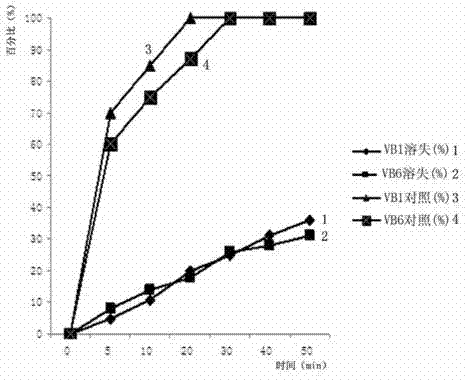

[0027] In this embodiment, vitamin B1 and vitamin B6, which are the most water-soluble, are taken as examples.

[0028] 1) Prepare a water-soluble vitamin solution: 40 grams of thiamine hydrochloride and 25 grams of VB6 are dissolved in an aqueous solution with a pH of about 5.0 at room temperature, and the volume of the water body is 500 ml;

[0029] 2) Prepare the water phase: Add 5 grams of xanthan gum to 500 ml of water. After the dissolution is complete, slowly add 25 grams of edible gelatin, and raise the water temperature to 60°C to promote the dissolution of the gelatin. After cooling down, slowly add The water-soluble vitamin solution is added and mixed uniformly as the water phase;

[0030] 3) Prepare the oil phase: add 100 grams of phospholipid oil to 20 liters of soybean oil, and stir well to form an oil phase;

[0031] 4) Prepare W / O emulsion and use it for post-spraying of feed: Slowly add the above water phase while stirring, and then homogenize under high pres...

Embodiment 2

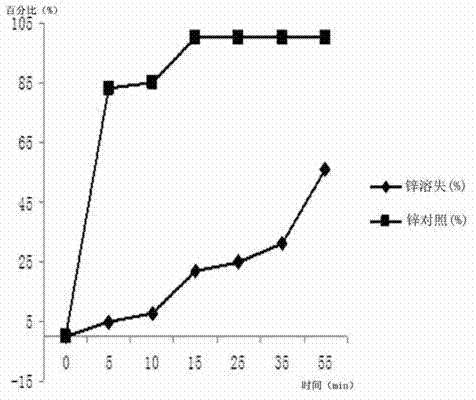

[0035] This embodiment takes water-soluble trace elements as an example.

[0036] 1) Prepare a water-soluble trace element solution: 120 grams of zinc sulfate heptahydrate is dissolved in an aqueous solution with a pH of about 5.0 at room temperature, and the volume of the water body is 250 ml;

[0037] 2) Prepare the water phase: Add 4.5 grams of xanthan gum to 900 ml of water. After the dissolution is complete, slowly add 90 grams of soybean protein, and raise the water temperature to 65°C to promote the dissolution of the gelatin. After cooling down, slowly add Add an aqueous solution of zinc sulfate and mix uniformly as the water phase;

[0038] 3) Prepare the oil phase: add 400 grams of phospholipid oil to 40 liters of peanut oil, and stir well to form an oil phase;

[0039]4) Prepare W / O emulsion and use it for post-spraying of feed: Slowly add the above water phase while stirring, and then homogenize under high pressure, with a homogenization pressure of 350MPa, to for...

Embodiment 3

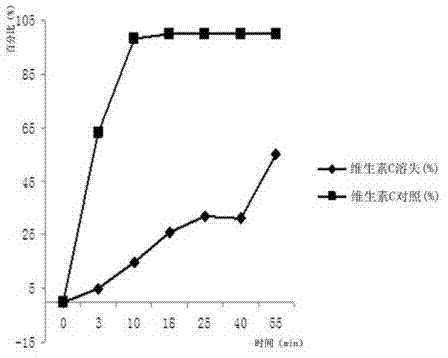

[0043] This embodiment takes vitamin C as an example.

[0044] 1) Preparation of water-soluble vitamin C solution: 10g of vitamin C is dissolved in an aqueous solution with a pH of about 5.0 at room temperature, and the volume of the water body is 100ml;

[0045] 2) Prepare the water phase: Add 18 grams of xanthan gum to 900 ml of water. After the dissolution is complete, slowly add 180 grams of hydrolyzed soybean protein, and raise the water temperature to 60°C to promote the dissolution of the gelatin. After cooling down, slowly add Slowly add the vitamin C solution and mix well to form the water phase;

[0046] 3) Prepare the oil phase: add 900 grams of phospholipid oil to 99 liters of fish oil, and stir well to form an oil phase;

[0047] 4) Prepare W / O emulsion and use it for post-spraying of feed: Slowly add the above water phase while stirring, and then homogenize under high pressure with a homogenization pressure of 500MPa to form a uniform and stable W / O emulsion. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com