Solid-phase extraction column and preparation method thereof

A solid-phase extraction column and extraction column technology, applied in chemical instruments and methods, other chemical processes, material separation, etc., can solve the problems of low sample matrix selectivity and poor purification effect, so as to increase accuracy and improve cleanliness. , the effect of low selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

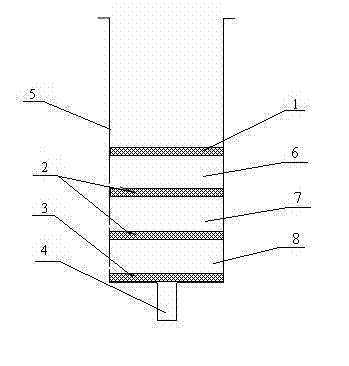

Image

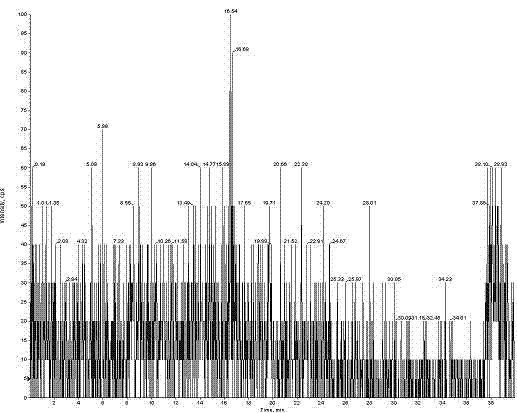

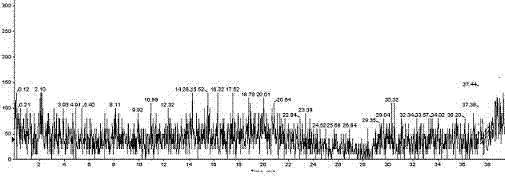

Examples

Embodiment 1

[0032] Preparation of graphitized carbon black

[0033] Take carbon powder and wash away metal and other organic impurities with sulfuric acid, hydrochloric acid, water, methanol, acetone and other organic solvents, dry it, add 0.1mol / L NaOH quantitatively, and place it in a high-temperature reforming furnace under the protection of high-purity helium. 10°C / min to raise the temperature to 1000°C, keep it warm for 12 hours, and quickly add 0.1mol / L K quantitatively after cooling down to room temperature 2 HPO 4 , heat up to 2000°C at 20°C / min, keep it warm for 12 hours, add K repeatedly after cooling down 2 HPO 4 Step, the product is washed with a large amount of water, washed and dried with acetone to obtain the product; tested by a specific surface area analyzer, the pore volume is 0.8-1.2 cm3 / g, and the specific surface area is 250-400 m2 / g.

Embodiment 2

[0035] Preparation of Polyaminated Fillers

[0036] Add porous polystyrene microspheres, concentrated hydrochloric acid (50:1, mass ratio), 2mol zinc chloride, and 1mol paraformaldehyde into the reactor, heat to 70°C, react for 24 hours, filter the product, wash with water until neutral, and then bake Dry, add concentrated ammonia water, ethylenediamine, and trimethylamine aqueous solution with a molar ratio of 3:2:1 into the reactor, react at 60°C for 48 hours under nitrogen protection, filter the product, wash with a large amount of water until it is neutral, and then dry it to obtain: Tested by the specific surface area analyzer, the specific surface area is 1000 m 2 / g.

Embodiment 3

[0038] Preparation of Hydrophobic Group Bonded Silica Gel

[0039] Use sodium citrate to reduce chloroauric acid to obtain gold nanoparticles with a diameter of 10-15nm. Another 50um fully porous silica gel is added to the reactor, and then 30ml of xylene, 20ml of mercaptosilane reagent, and 15ml of pyridine are added in order to react under reflux for 24 hours. Then cool down, wash the product with toluene, dichloromethane, methanol, and acetone, then dry it, add it to another reactor, add the gold nanoparticles prepared at the beginning, then add an excess of n-octadecyl mercaptan, and heat and reflux for 48 hours. The product was filtered and washed with methanol and acetone and then dried to obtain the obtained product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com