Method for preparing polycarboxylic acid / methyl-cyclopentadienyl-manganese-tricarbony (MMT) nanocomposites by adoption of atom transfer radical polymerization (ATRP) technique

A nano-composite material and polycarboxylic acid technology, applied in the field of preparing nano-composite materials, can solve the problems of wide molecular weight distribution, uncontrollable molecular weight, difficulty in obtaining a single intercalated polycarboxylic acid/MMT nano-composite material, etc., and achieve a regular structure. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

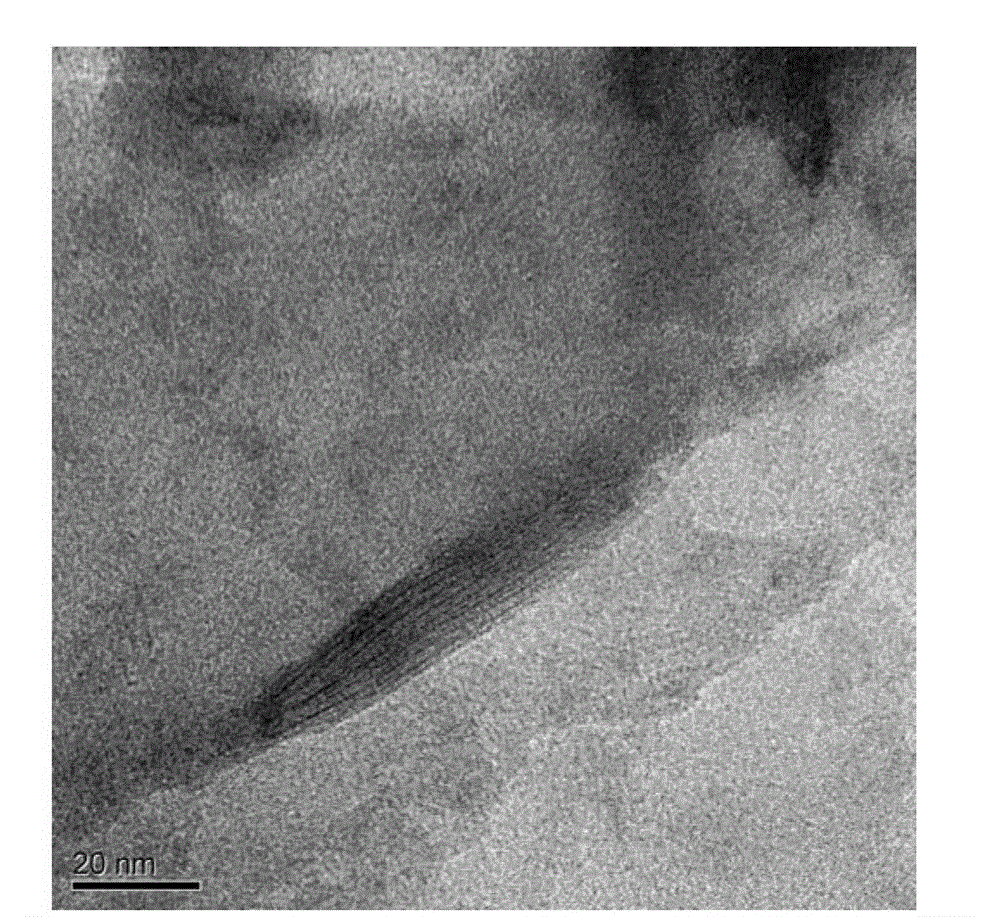

Image

Examples

Embodiment 1

[0022] 1) Dissolve 10g of 4-pentenoic acid in 20g of distilled water, then use NaOH aqueous solution to adjust the pH value of the obtained 4-pentenoic acid aqueous solution to 9, and transfer it to a reaction flask; then add 4-pentenoic acid aqueous solution Add 0.100g of organically modified montmorillonite (OMMT), 0.100g of cuprous chloride and 0.300g of 1,4,8,11-tetramethyl-1,4,8,11-tetraazacyclic Tetradecane (Me4cyclam), then the reaction flask where the reaction system obtained is evacuated to make the reaction flask in a vacuum state, and then nitrogen is passed into the container where the reaction system is located, so that the reaction system is in an oxygen-free environment; Under the protection of nitrogen, the reaction system was heated to 60°C in a water bath and stirred for 12 hours to obtain a poly-4-pentenoic acid sodium / MMT nanocomposite solution; wherein, the organically modified montmorillonite (OMMT) was obtained by using It was obtained by modifying montm...

Embodiment 2

[0025] 1) Dissolve 10g of methacrylic acid in 20g of distilled water, then use solid NaOH to adjust the pH value of the obtained methacrylic acid aqueous solution to 8.6, and transfer it into a reaction bottle; then add 0.025g of organic Modified montmorillonite (OMMT), 0.025g of cuprous bromide and 0.075g of 2,2'-bipyridyl (Bpy), and then vacuumize the reaction flask where the obtained reaction system is located, so that the inside of the reaction flask is In a vacuum state, argon gas is introduced into the container where the reaction system is located, so that the reaction system is in an oxygen-free environment; under the protection of argon gas, the reaction system is heated to 60°C in a water bath, and the reaction is stirred for 12 hours to obtain the polymer Sodium methacrylate / MMT nanocomposite solution; wherein, organically modified montmorillonite (OMMT) is obtained by modifying montmorillonite (MMT) with commercially available 2-bromoethyltrimethylammonium bromide. ...

Embodiment 3

[0028] 1) Dissolve 10g of trans-2-hexenoic acid in 20g of distilled water, then use NaOH aqueous solution to adjust the pH value of the obtained trans-2-hexenoic acid solution to 8.5, and transfer it to the reaction flask; 0.025 g of organically modified montmorillonite (OMMT), 0.025 g of cuprous bromide and 0.075 g of tris-(N,N-dimethylaminoethyl)amine (Me 6 TREN), then the reaction flask where the obtained reaction system is located is evacuated to make the reaction flask in a vacuum state, and then nitrogen is passed into the container where the reaction system is located, so that the reaction system is in an oxygen-free environment; under the protection of nitrogen , using a water bath to heat the reaction system to 60°C and then stir and react for 12 hours to obtain a polytrans-2-hexenosodium / MMT nanocomposite solution; wherein, the organically modified montmorillonite (OMMT) is commercially available It is obtained by modifying montmorillonite (MMT) with 2-bromoethyltrim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com