Magnetic MFe2O4/C/M' compound and preparation method thereof using aniline small organic molecules as a carbon source

A technology of small molecules and complexes, applied in the direction of magnetism of organic materials/organic magnetic materials, magnetic objects, magnetic materials, etc., can solve the problems of high cost of carbon sources, uneconomical benefits, etc., to achieve adsorption, increase surface area, High magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

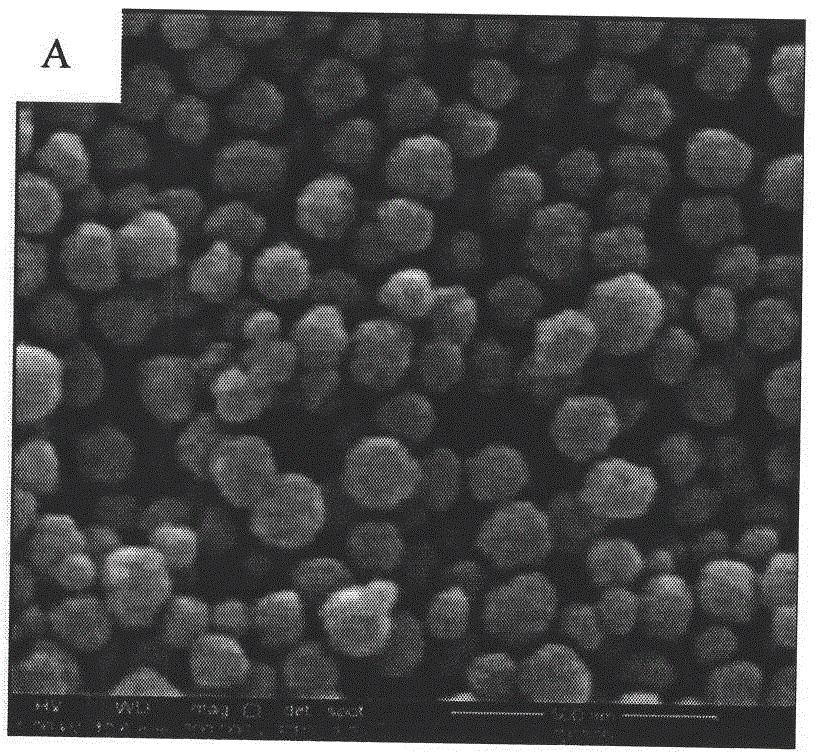

[0035] (1) Fe 3 o 4 Preparation of microspheres

[0036] Prepared by solvothermal method, weigh 0.3g trisodium citrate dihydrate and disperse in 30mL ethylene glycol, stir for 9 hours until dissolved, then add 3.0g sodium acetate trihydrate, 0.819g FeCl 3 ·6H 2 O, stirred until dissolved, then transferred the mixture to a reaction kettle, and reacted at 200°C for 10h. Cool to room temperature, wash with ethanol and water several times, and dry in a vacuum oven at 50°C to obtain Fe 3 o 4 Microspheres.

[0037] (2) Fe 3 o 4 Preparation of / C Composite Nanomaterials

[0038] Prepare a 0.04 g / mL ethanol solution of o-phenylenediamine. Weigh the Fe prepared in experiment (1) 3 o 4 20mg, dispersed in 35mL water, ultrasonically dispersed for 10min, then added 5mL ethanol solution of o-phenylenediamine, stirred for several minutes, transferred to a reaction kettle, and reacted at 160°C for 36h. Cool to room temperature, wash with water several times, and dry in a vacuum ov...

Embodiment 2

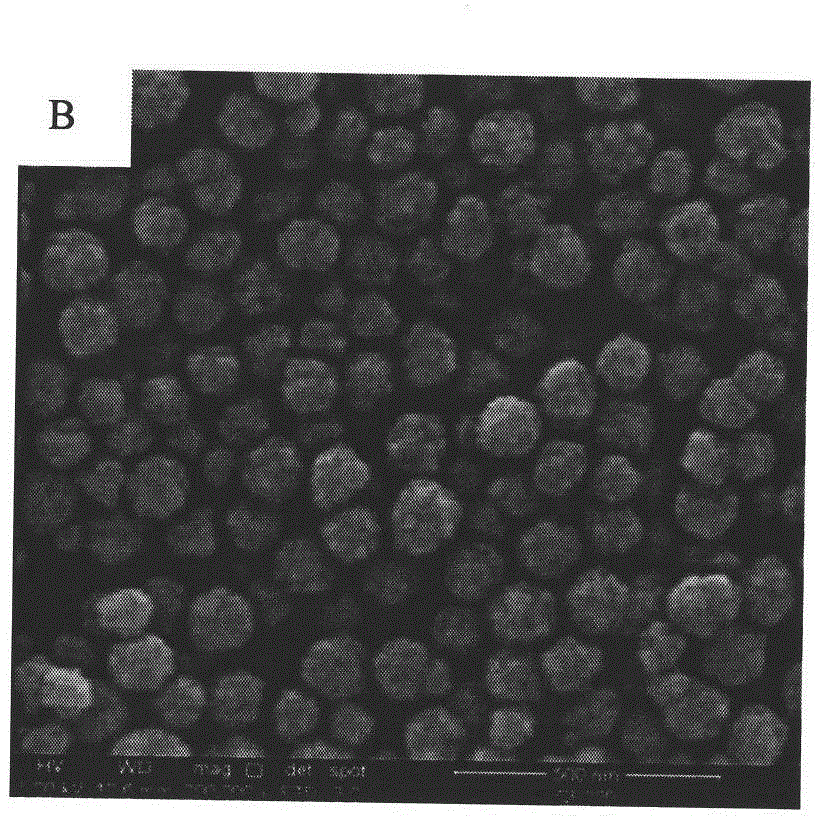

[0045] (1) Fe 3 o 4 Preparation of microspheres

[0046] Prepared by solvothermal method, weigh 1.0g trisodium citrate dihydrate and disperse in 30mL ethylene glycol, stir for 9 hours until dissolved, then add 3.0g sodium acetate trihydrate, 0.819g FeCl 3 ·6H 2 O, stirred until dissolved, then transferred the mixture to a reaction kettle, and reacted at 230°C for 20h. Cool to room temperature, wash several times with ethanol and ultrapure water, and dry in a vacuum oven at 50°C to obtain Fe 3 o 4 Microspheres.

[0047] (2) Fe 3 o 4 Preparation of / C Composite Nanomaterials

[0048] Weigh the Fe obtained in experiment (1) 3 o 4 20mg, ultrasonically dispersed in 15mL of 0.02g / mL o-phenylenediamine ethanol solution, stirred for 5h, filtered, washed with ethanol three times, and vacuum-dried at 50°C. Then, the sample was transferred to a muffle furnace, heat-treated at 800 °C for 10 h under a nitrogen atmosphere, and cooled to room temperature to obtain Fe 3 o 4 / C do...

Embodiment 3

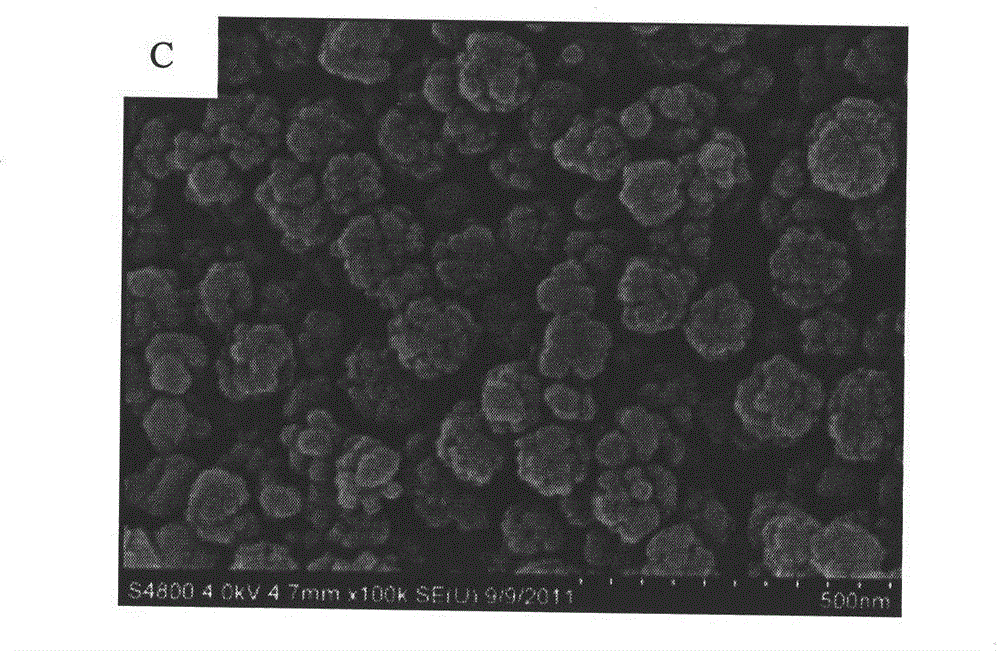

[0055] (1) Fe 3 o 4 Preparation of nanoparticles

[0056] Prepared by solvothermal method, weigh 0.318g trisodium citrate dihydrate and disperse in 30mL ethylene glycol, stir for 9 hours until dissolved, then add 1.5g sodium acetate trihydrate, 0.819g FeCl 3 ·6H 2 O, stirred until dissolved, then transferred the mixture to a reaction kettle, and reacted at 200°C for 10h. Cool to room temperature, wash several times with ethanol and ultrapure water, and dry in a vacuum oven at 50°C to obtain 300nm Fe 3 o 4 Microspheres. Then the microspheres were mixed with methanol and ball milled under the protection of argon. Get 7-10nm Fe 3 o 4 Nanoparticles.

[0057] (2) Fe 3 o 4 Preparation of / C Composite Nanomaterials

[0058] Prepare 0.1 g / mL trisodium citrate dihydrate aqueous solution and 0.04 g / mL m-phenylenediamine ethanol solution respectively. Weigh the Fe obtained in experiment (1) 3 o 4 4mg, dispersed in 33mL water, ultrasonically dispersed for 10min, then added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com