Preparation method of vanadium oxide and lithium iron phosphate composite materials with high tap density

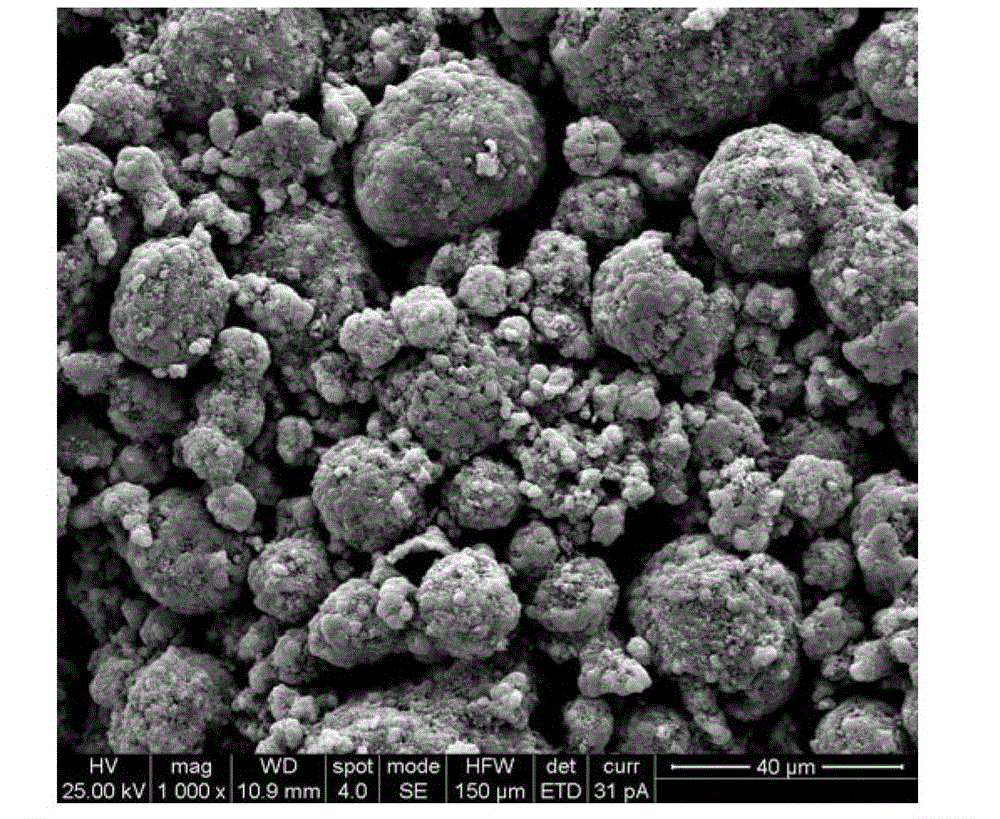

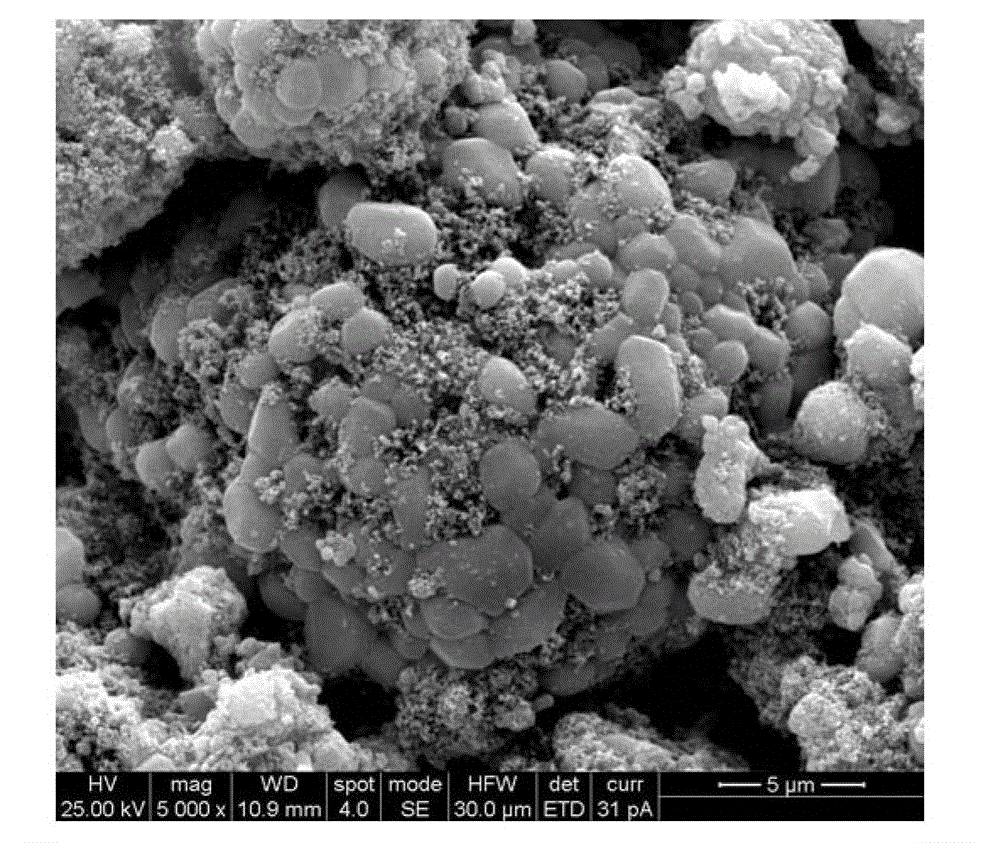

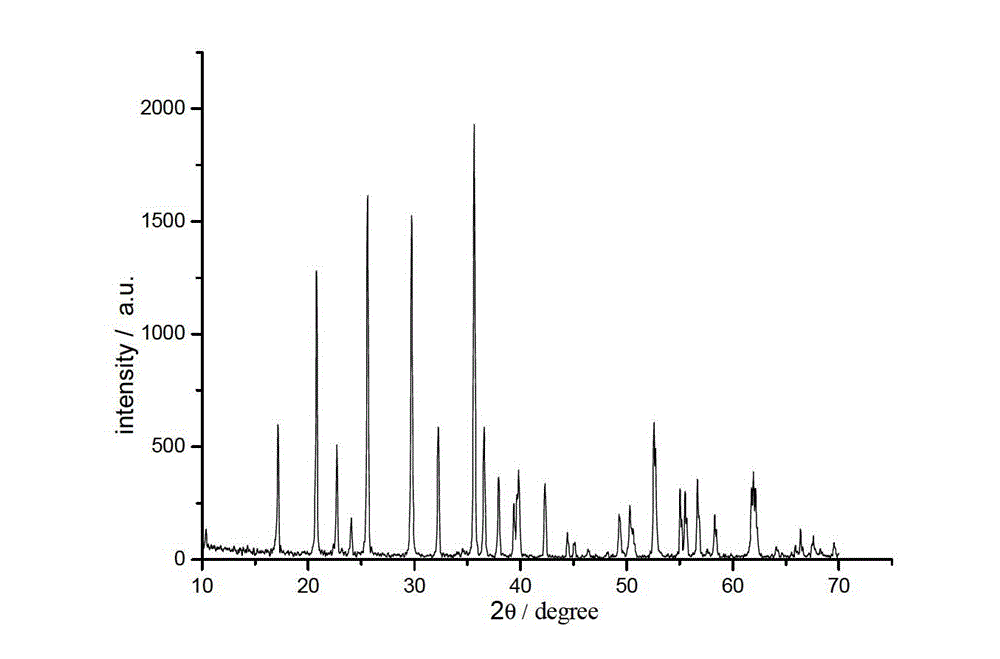

A technology of lithium iron phosphate and vanadium oxide, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of reducing the tap density of lithium iron phosphate, hindering lithium iron phosphate grains, and reducing the gram capacity of materials, and achieving improvement The effect of lithium ion diffusion ability, round surface morphology and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of a high tap density vanadium oxide and lithium iron phosphate composite material comprises the following steps:

[0030] According to the molar ratio of elements (n Li : n Fe : n P = 1:1:1), wherein lithium carbonate 2955.2 g, ferrous oxalate 14392 g and ammonium dihydrogen phosphate 9202.4 g, adding grinding media in the deionized water system and mixing ball milling under nitrogen protection for 8 hours, the slurry was spray-dried Drying treatment is carried out, and the obtained lithium iron phosphate precursor powder is pre-sintered at 550° C. for 12 hours under an inert gas protection atmosphere to obtain a lithium iron phosphate precursor;

[0031] According to the molar ratio of elements (n Li : n V = 1: 0.005), 106.1 g of vanadyl acetylacetonate, 1034.3 g of glucose and the above-mentioned precursor were mixed and ball-milled for 10 hours in a dehydrated ethanol system, and the slurry was dried in vacuum at 100° C. to obtain the p...

Embodiment 2

[0034] According to the molar ratio of elements (nLi : n Fe : n P = 1:1:1), wherein 2955.2 g of lithium carbonate, 14392 g of ferrous oxalate and 9202.4 g of ammonium dihydrogen phosphate were added to the deionized water system and mixed with ball milling for 8 hours under nitrogen protection, and the slurry was spray dried. Drying treatment, the obtained lithium iron phosphate precursor powder is pre-sintered at 550°C for 12 hours under an inert gas protection atmosphere to obtain a lithium iron phosphate precursor;

[0035] According to the molar ratio of elements (n Li : n V = 1 : 0.01), 212.2 g of vanadyl acetylacetonate, 1034.3 g of glucose and the above-mentioned precursor were mixed and ball-milled in an anhydrous ethanol system for 10 hours, and the slurry was vacuum-dried at 100°C to obtain the precursor powder of the composite material;

[0036] The obtained composite material precursor powder was added to a dry powder molding machine, and molded at a pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com