Paint for reducing carburization of evaporative pattern steel castings

A technology for steel castings and lost foam, which is applied in the field of iron and steel casting. It can solve problems such as technical obstacles in the preparation of coatings for lost foam castings, and achieve the effects of good suspension, high-temperature air permeability, and high-temperature strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

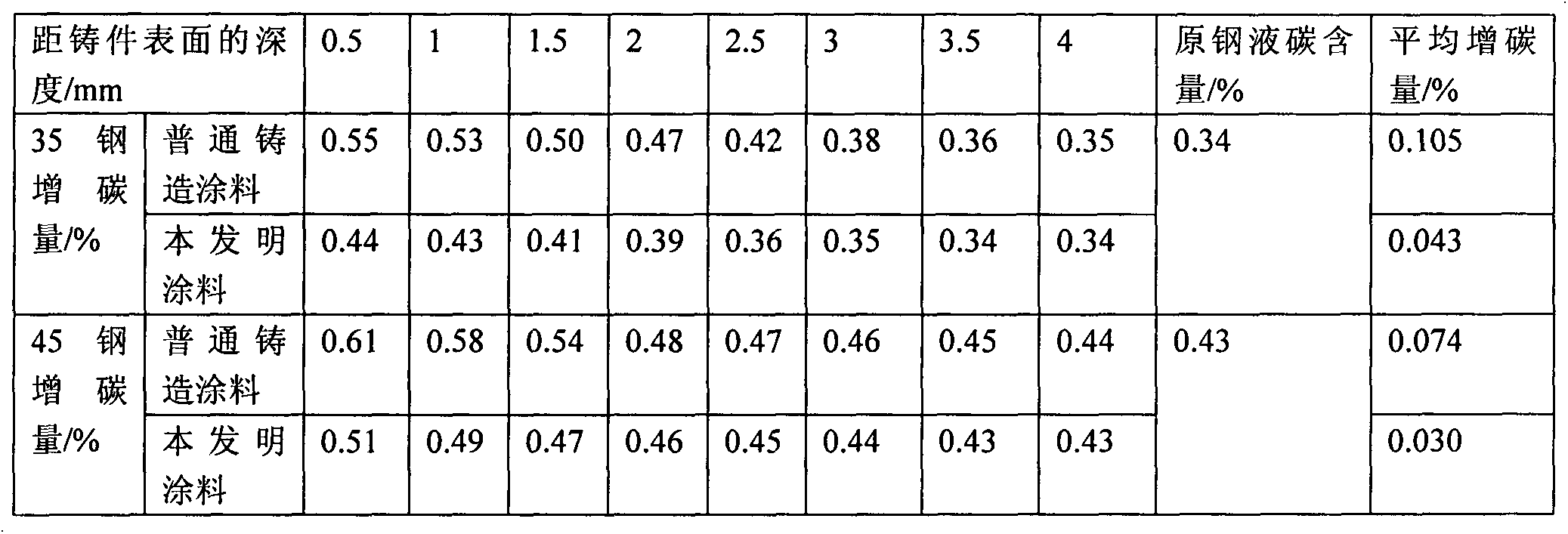

Image

Examples

Embodiment 1

[0016] Embodiment 1, get 50 parts of chromite powder, 30 parts of brown corundum powder, 20 parts of bauxite, 5 parts of limestone powder, 2 parts of iron oxide, 1.2 parts of cryolite, 3 parts of silica sol, 4 parts of aluminum sulfate, calcium 2.5 parts of base bentonite, 2 parts of attapulgite, 2.5 parts of VAE emulsion (vinyl acetate-ethylene copolymer emulsion), 0.125 parts of sodium carbonate, 1.5 parts of sodium carboxymethyl cellulose, 0.02 parts of OP-10 polyvinyl alkyl alcohol ether, 0.015 parts of organosilicon defoamer, 0.02 parts of sanitin, according to the conventional preparation method of paint, the above-mentioned components are mixed with 125 parts of water and stirred evenly to obtain the paint product of the present invention.

Embodiment 2

[0017] Embodiment 2, get 45 parts of chromite powder, 40 parts of brown corundum powder, 15 parts of bauxite, 4 parts of limestone powder, 1 part of iron oxide, 1.5 parts of cryolite, 2 parts of silica sol, 5 parts of aluminum sulfate, calcium base 2 parts of bentonite, 1.5 parts of attapulgite, 3 parts of VAE emulsion (vinyl acetate-ethylene copolymer emulsion), 0.1 part of sodium carbonate, 2 parts of sodium carboxymethyl cellulose, 0.01 part of OP-10 polyvinyl alkyl alcohol ether, organic 0.03 parts of silicon defoamer, 0.02 parts of sanitin, according to the conventional preparation method of paint, the above-mentioned components are mixed with 120 parts of water and stirred evenly to obtain the paint product of the present invention.

Embodiment 3

[0018] Embodiment 3, take 60 parts of chromite powder, 30 parts of brown corundum powder, 10 parts of bauxite, 6 parts of limestone powder, 2.5 parts of iron oxide, 1.3 parts of cryolite, 4 parts of silica sol, 3 parts of aluminum sulfate, calcium base 3 parts of bentonite, 2.5 parts of attapulgite, 2 parts of VAE emulsion (vinyl acetate-ethylene copolymer emulsion), 0.15 part of sodium carbonate, 1 part of sodium carboxymethyl cellulose, 0.03 part of OP-10 polyvinyl alkyl alcohol ether, organic 0.05 part of silicon defoamer, 0.04 part of sanitin, according to the conventional preparation method of paint, the above-mentioned components are mixed with 130 parts of water and stirred evenly to obtain the paint product of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com