POSS acrylate/p-vinylbenzylazide copolymer coat material and its preparation method

A technology for vinylbenzyl and acrylate, which is used in coatings, plant fibers, textiles and papermaking, etc., to achieve the effects of simple and convenient preparation and operation, good thermal stability and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Azidation of styrene benzyl chloride

[0032] Add 25mL DMSO and 2mL 4-styrene benzyl chloride into a 50mL two-necked flask, put the two-necked flask in a 60°C oil bath, add 1.7g sodium azide and 0.215g potassium iodide, and raise the temperature of the oil bath to 80 ℃, vacuum, argon, repeated three times for 12 hours, stop the reaction, the reaction solution was cooled to room temperature, poured into 100mL of water, extracted twice with anhydrous ether to obtain a yellow liquid product, yield Y 1 85%.

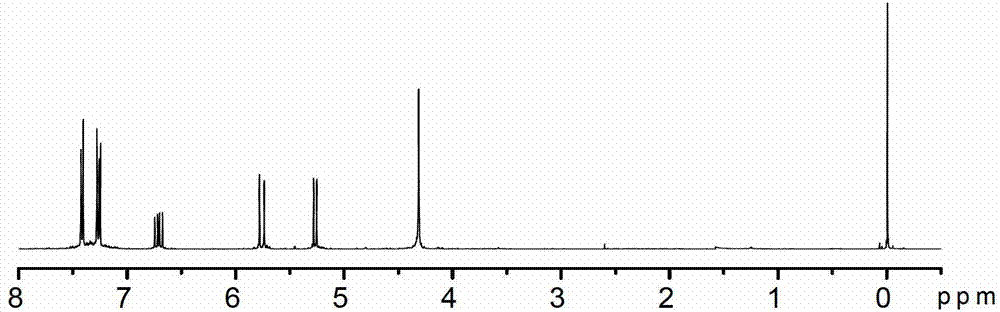

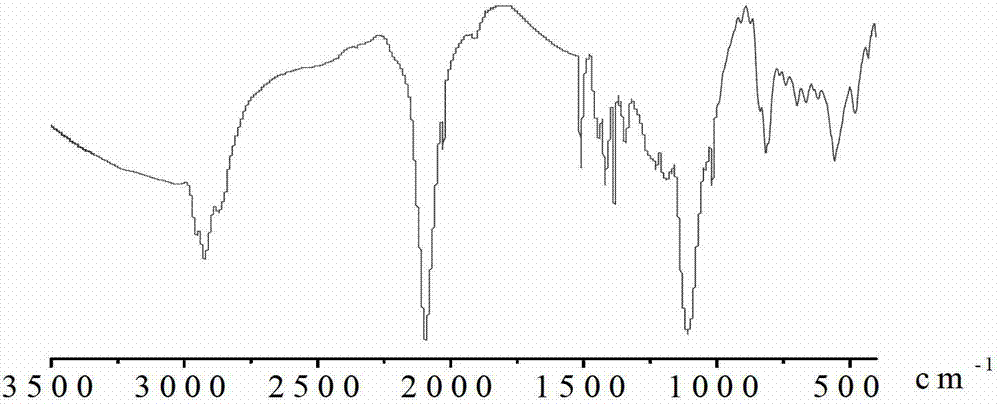

[0033] (2) Preparation of POSS acrylate / p-vinylbenzyl azide copolymer

[0034] Dissolve 0.667g styrylbenzyl azide, 0.1187g POSS (meth)acrylate, 0.0136g CDB, 0.00164g in 1.5mL of THF, freeze-thaw and degas for 3~5 times, and then under the protection of argon Polymerization at 65°C. After 48 hours of reaction, liquid nitrogen was quenched to stop the reaction. The methanol volume ratio was selected to be 1:20, and the precipitation was repeated for 3 times. The ye...

Embodiment 2

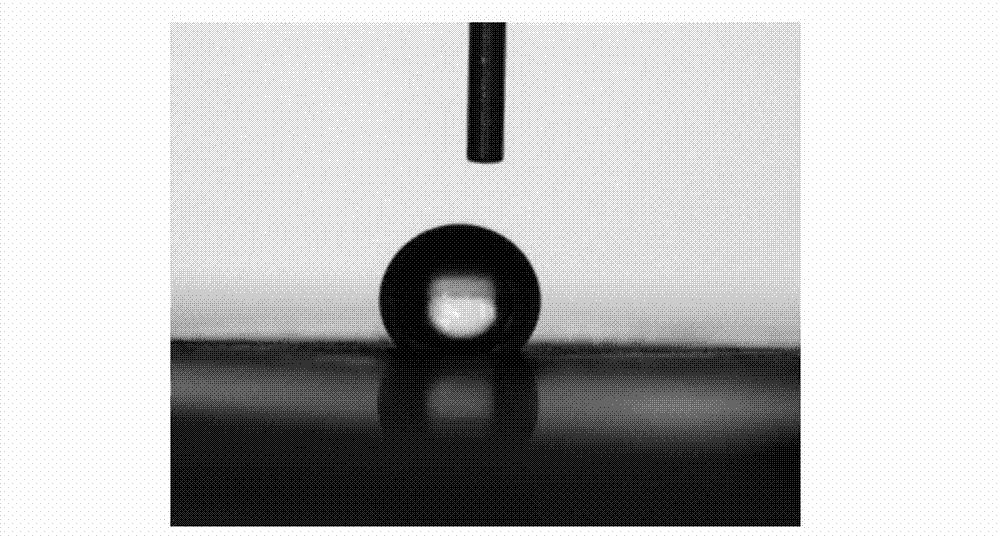

[0041] Add 25mL DMSO and 1.5mL pentadienoyl chloride into a 50mL two-necked flask, put the two-necked flask in a 60°C oil bath, add 1.9g sodium azide and 0.215g potassium iodide, and raise the temperature of the oil bath to 80°C after the addition is complete , vacuum, argon, repeated three times for 12 hours, stop the reaction, the reaction solution was cooled to room temperature and poured into 110mL of water, extracted twice with anhydrous ether to obtain a yellow liquid product, yield Y 1 88%. Dissolve 0.8g pentadienoyl azide, 0.1187g POSS (meth)acrylate, 0.0136g CDB, 0.00164g in 1.5mL of THF, freeze-thaw and degas for 3~5 times, and then under the protection of argon Polymerization at 65°C. After 48 hours of reaction, liquid nitrogen was quenched to stop the reaction. The methanol volume ratio was selected to be 1:20, and the precipitation was repeated for 3 times. The yellow product was obtained by vacuum drying, and the yield was Y 2 73%. The substrate (glass or cotto...

Embodiment 3

[0043] Add 25mL DMSO and 1.8mL 4-chlorophenyl methacrylate into a 50mL two-necked flask, put the two-necked flask in a 60°C oil bath, add 2.1g sodium azide and 0.21g potassium iodide, and drain the oil after the addition The temperature of the bath was raised to 80°C, evacuated, and argon flowed, and the reaction was repeated three times for 12 hours, and the reaction was stopped. After the reaction solution was cooled to room temperature, it was poured into 120 mL of water, extracted twice with anhydrous ether, and the product of a yellow liquid was obtained. Y 1 85%. Dissolve 1g of 4-phenylazide methacrylate, 0.1187g of POSS (meth)acrylate, 0.0136g of CDB, and 0.00164g in 1.5mL of THF, and then freeze-thaw and degas 3~5 times in argon protection Polymerization at 65°C. After 48 hours of reaction, liquid nitrogen was quenched to stop the reaction. The methanol volume ratio was selected to be 1:20, and the precipitation was repeated 3 times. The yellow product was obtained by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com