Deep treatment reuse method for cellulose ethanol production wastewater

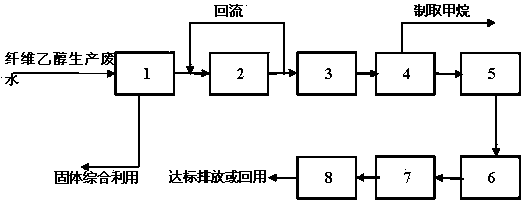

A technology for the production of wastewater and cellulosic ethanol, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of high influent load, decreased biogas generation rate, and anaerobic treatment of wastewater Ineffectiveness and other problems, to achieve water-saving sewage discharge, reduce sewage discharge, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The treatment method of the present invention is used to treat the waste water of a domestic medium-scale test-scale cellulosic ethanol production plant. The device uses corn stalks as raw materials and mainly adopts steam acid explosion pretreatment, enzymatic hydrolysis, sugar solution fermentation, ethanol concentration and rectification purification to produce cellulosic ethanol. The main pollutant COD in wastewater is 129050 mg / L ( Chromium method, the same below), BOD 5 68600 mg / L, sulfate radical 9290 mg / L, total salt content 9.69%, ammonia nitrogen 38.8 mg / L, carboxylic acid 4600 mg / L, furan 230 mg / L, phenol 600 mg / L. The specific operating conditions and structures are shown in Table 1.

[0039] Table 1 The composition and treatment effect of the main processing units in Example 1.

[0040] Handling unit name Processing device scale and main components Main operating conditions and control parameters Treatment effluent or effect Neutra...

Embodiment 2

[0042] Using the treatment device of Example 1 to treat the same sewage as in Example 1, and changing the operating conditions of each treatment unit, the wastewater treatment effect obtained is shown in Table 2.

[0043] Table 2 The composition and treatment effect of the main processing units in Example 2.

[0044] Handling unit name Processing device scale and main components Main operating conditions and control parameters Treatment effluent or effect Neutralize precipitation The neutralization sedimentation tank is made of plexiglass, 20L, with a processing capacity of 10L / h, with Ca(OH) 2 On-line adding system and stirring device, the sediment is discharged regularly, and the discharge cycle is 24 hours. Continuous operation, water inflow 2 L / h, Ca(OH) 2 The mass fraction is 5%. The COD of the effluent is about 120,000 mg / L, and the pH is 6.5. Dissolved air flotation Pressurized dissolved air flotation device with a processing capacity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com