Bicyclo-iridium complex, preparation method of complex, organic light emitting diode (OLED) and preparation method of OLED

A technology of electroluminescent devices and iridium complexes, which is applied in the fields of organic semiconductor devices, electric solid devices, semiconductor/solid device manufacturing, etc., can solve problems such as backward research progress, difficulties, and small energy level difference of compounds, and achieve external quantum efficiency High, stable luminous performance, high saturation of red light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] The embodiment of the present invention also provides a preparation method of the above-mentioned bicyclic iridium complex, and the preparation method specifically includes the following steps:

[0080] Step (1), dissolving phosphorus pentoxide in m-cresol, then adding 1-naphthalene-1-yl-ethanone and anthranilaldehyde derivatives for dehydration reaction to obtain 2-naphthalene- 1-yl-quinoline derivatives;

[0081]

[0082] Step (2), the IrCl 3 ﹒ 3H 2 O is dissolved in water, adding the 2-naphth-1-yl-quinoline derivative and the first organic solvent, in N 2 Stir in the dark in the environment to obtain the dichloro bridge compound of iridium shown in the following structural formula;

[0083]

[0084] In step (3), the dichloro bridge compound of iridium is dissolved in a second organic solvent, and stirred with an auxiliary ligand under the action of a base to obtain the bicyclic iridium complex.

[0085] Wherein, in step (1), preferably, the dosage ratio of...

Embodiment 1

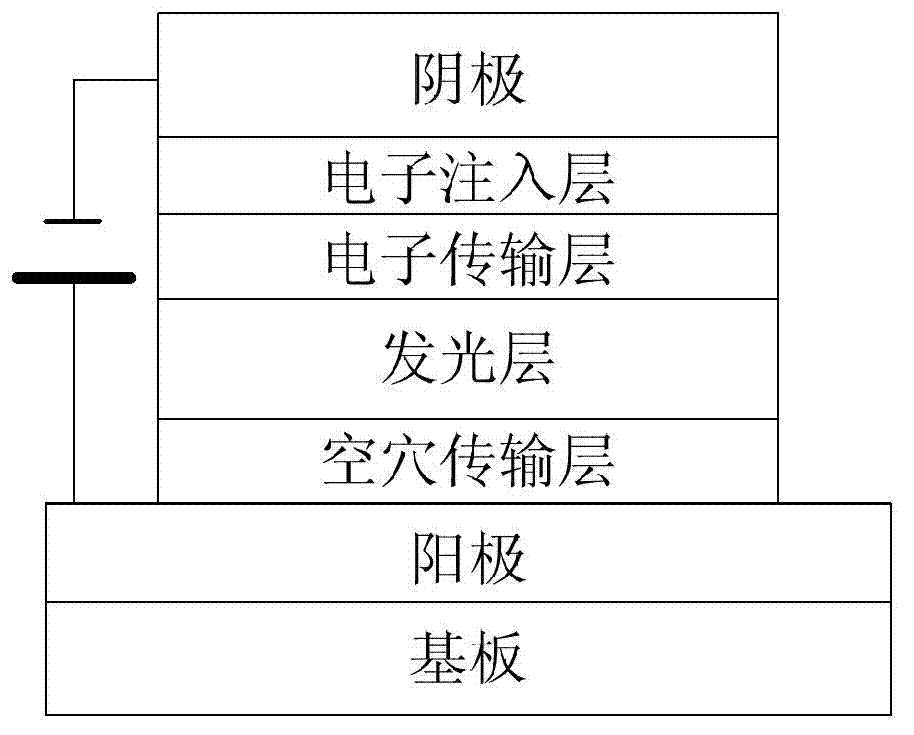

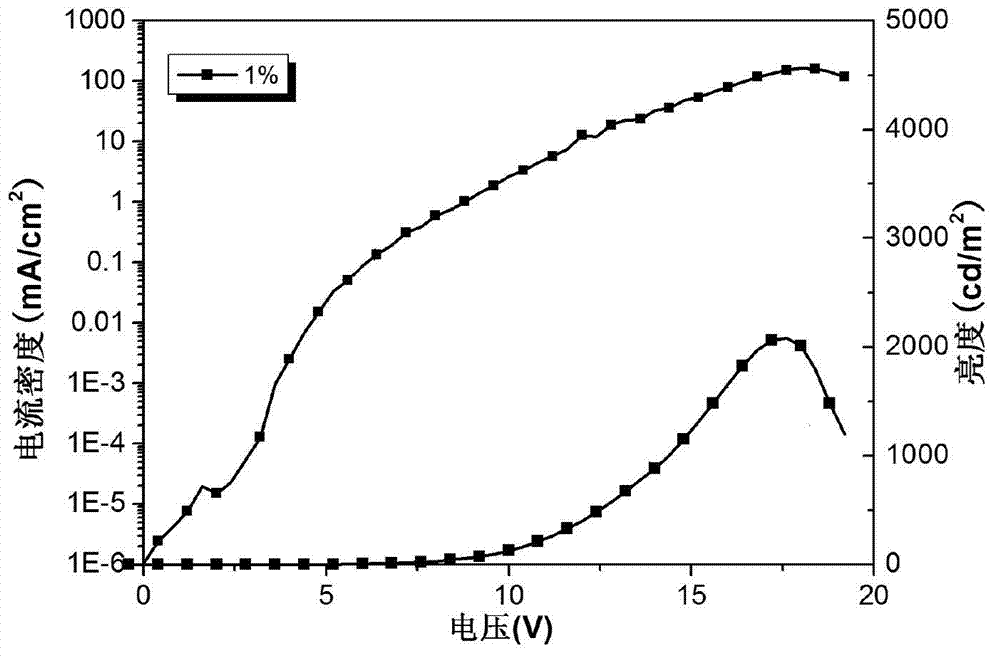

[0109] In this embodiment, the structure of the organic electroluminescent device is: the anode is made of indium tin oxide (ITO); the hole transport layer is made of PEDOT / PSS (3,4-ethylenedioxythiophene polymer doped polystyrene sulfonic acid ), the thickness is 40nm; the thickness of the light-emitting layer is 70nm; the electron transport layer is TPBI (1,3,5-tris(1-phenyl-1H-benzimidazol-2-yl)benzene), the thickness is 30nm; the electron injection The layer uses cesium fluoride (CsF) with a thickness of 1.5nm; the cathode uses aluminum (Al) with a thickness of 120nm. Among them, in the light-emitting layer, PVK, PBD and (NPQ) 2 The mass ratio of Ir(pic) is 69:30:1.

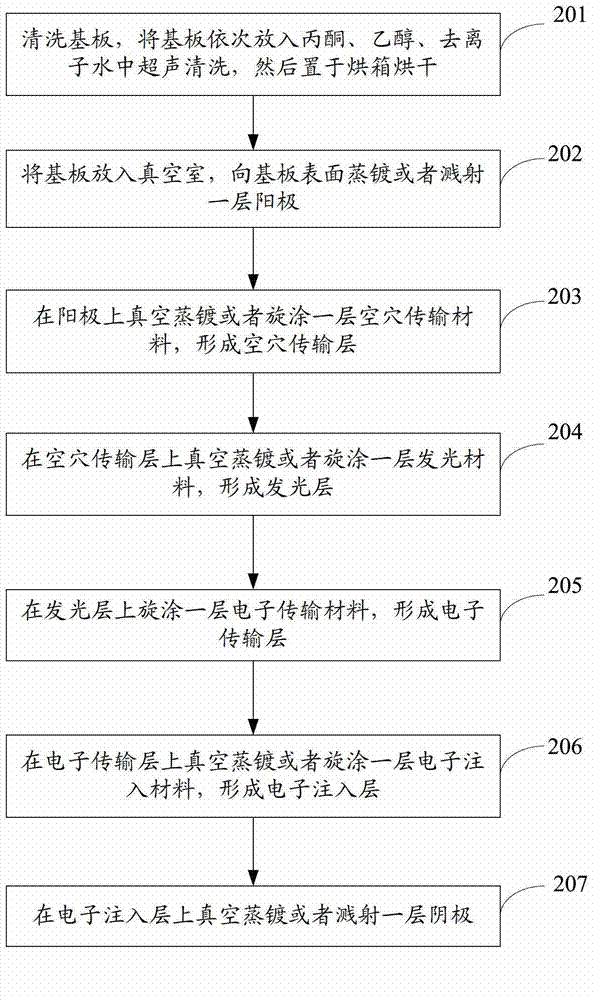

[0110] The preparation method of the organic electroluminescence device of the present embodiment comprises the following steps:

[0111] A: After cleaning the indium tin oxide (ITO) conductive glass substrate ultrasonically in acetone, detergent, deionized water and isopropanol liquid, put it in an oven fo...

Embodiment 2

[0118] In this embodiment, the structure of the organic electroluminescent device is as follows: the anode is made of ITO; the hole transport layer is made of PEDOT / PSS with a thickness of 40nm; the thickness of the light-emitting layer is 70nm; CsF is used with a thickness of 1.5nm; the cathode is made of Al with a thickness of 120nm. Among them, in the light-emitting layer, PVK, PBD and (NPQ) 2 The mass ratio of Ir(pic) is 69:29:2.

[0119] The preparation method of the organic electroluminescence device of the present embodiment comprises the following steps:

[0120] A: After ultrasonically cleaning the indium tin oxide (ITO) conductive glass substrate in acetone, detergent, deionized water and isopropanol liquid, put it in an oven for drying, and then perform oxygen plasma treatment on the cleaned substrate to improve the ITO The work function can further remove the residual organic dirt on the surface of the ITO substrate and improve the contact angle of the substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com