Preparation method of water-soluble olive polyphenol with bacteriostatic and preserved activity on meat products

A technology for olive polyphenols and water-soluble oil, which is applied in the fields of biomedicine and food applications, can solve the problems of human toxicity, narrow antibacterial spectrum, and change in the content of active ingredients, and achieves the effects of easy production, good water solubility and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of water-soluble olive polyphenols with antibacterial and fresh-keeping activity on meat products

[0037] The first step, raw material pretreatment

[0038] Screen and dry fresh olive leaves at low temperature, crush them into powders below 0.5cm, such as 200nm, 300nm, 500nm, 1000nm, 10mm, 50mm, 100mm, 200mm, 300mm, 500mm, preferably 500nm, 1000nm, 10mm, 50mm, 100mm;

[0039] The second step, preparation of different olive extracts

[0040] A water extract: the mass ratio of dried olive leaves to deionized water is 1:15-30, extract at 90-100°C for 2-4 hours, extract twice, filter, combine extracts, concentrate under reduced pressure, and vacuum freeze the concentrate Dry, the moisture content of the solid powder is less than 10%;

[0041] B alcohol extract: the mass ratio of olive dry leaves to alcohol solvent is 1:6-20, extract at 70-80°C for 2-4 hours, extract twice, filter, combine extracts, concentrate under reduced pressure, and vacuum free...

Embodiment 2

[0054] Embodiment 2 olive extract preparation

[0055] 1. Sample pretreatment

[0056] Rinse the fresh olive leaves with clean water and dry them at room temperature until the surface of the leaves is completely dry. Put them in a vacuum drying oven in batches and dry them at a vacuum of 740mmHg and a temperature of 50°C. Open the vacuum drying oven every 1h until the leaves are completely dry. Completely dry, then pulverize the dry olive leaves with a multifunctional grinder, pulverize to a fine powder, pass through a 50-mesh sieve, and use the olive leaf powder for later use.

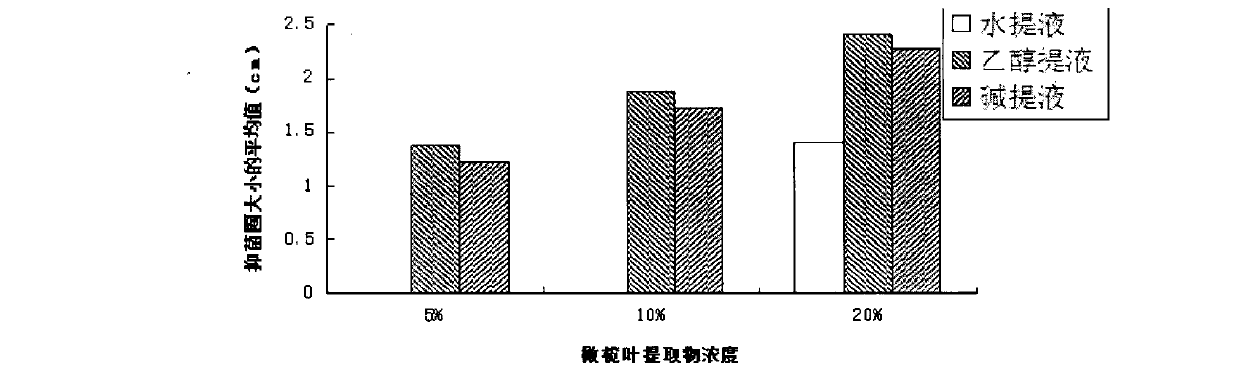

[0057] 2. Extraction with different solvents

[0058] 1) Water extraction method

[0059] Weigh 20g of olive leaf powder into 8 triangular flasks, add 400ml of distilled water each to make a solid-liquid ratio of 1:20, put them in a constant temperature shaker, and extract at an oscillation frequency of 130r / s and 90°C. The extraction time is respectively The content of total flavonoids and polyphe...

Embodiment 3

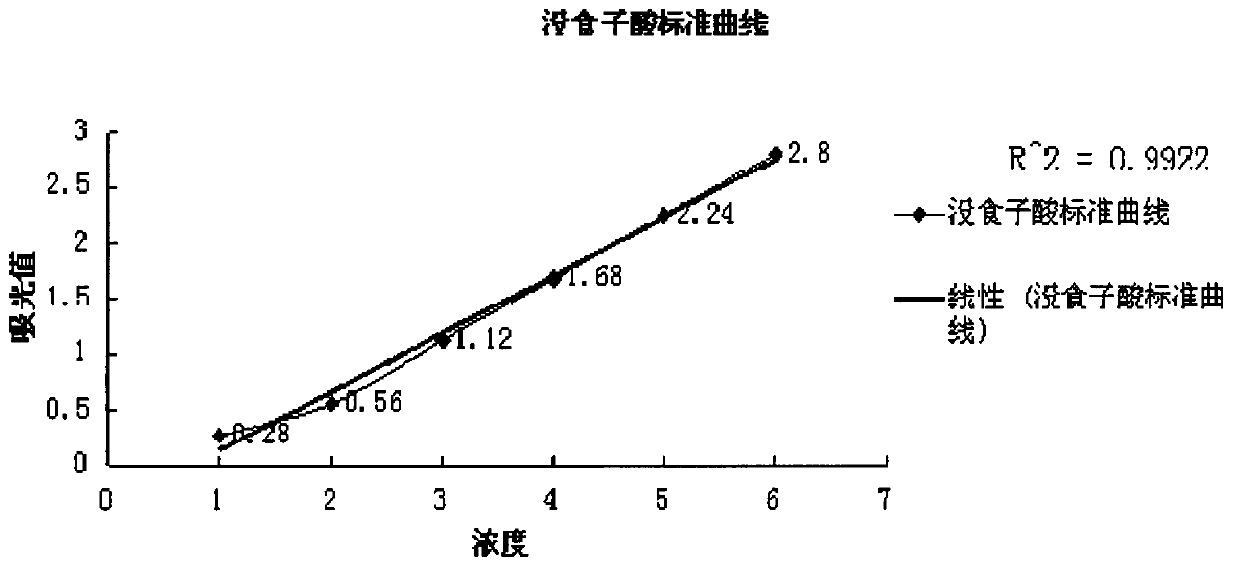

[0066] The detection of embodiment 3 olive leaf extract polyphenols and flavonoids

[0067] 1. Sample pretreatment

[0068] The extracts of different extraction methods were centrifuged in a low-speed centrifuge at a speed of 3000r / s for 10min, and 20ml of the supernatant was used for the determination of flavonoids and polyphenols, and the rest of the supernatant was collected for later use.

[0069] 2. Detection of flavonoids

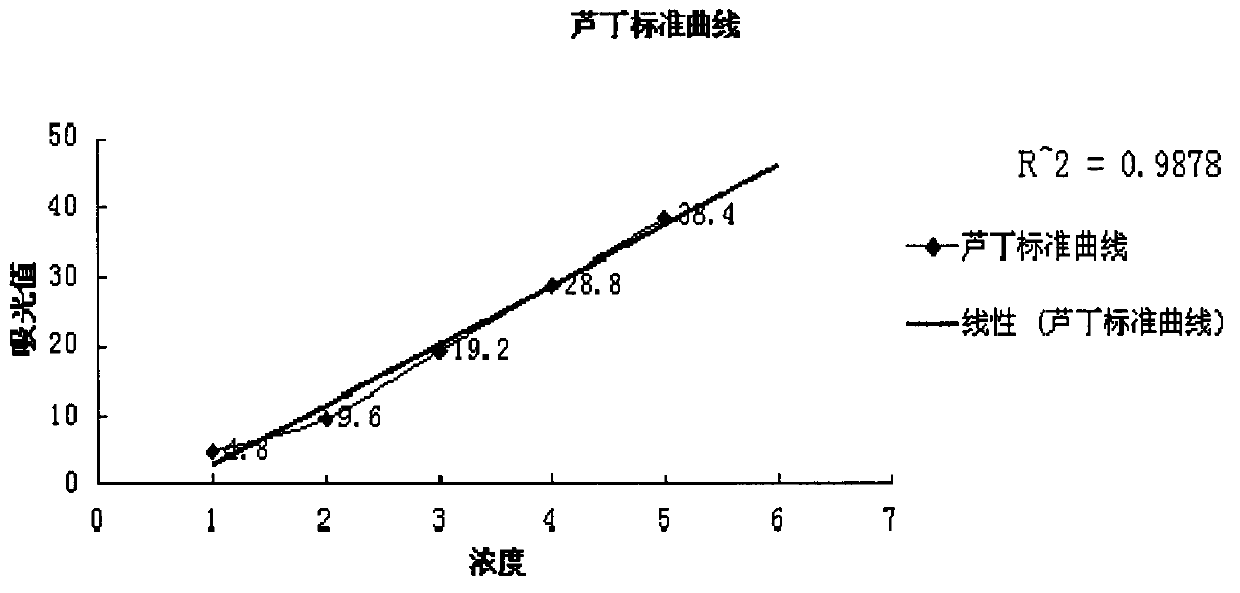

[0070] a) Preparation of flavonoids standard curve

[0071] Accurately weigh 4.8 mg of rutin with a constant weight, dissolve it in 95% ethanol, and dilute it in a 50 mL volumetric flask with 30% ethanol to prepare a standard solution of rutin with a concentration of 0.096 mg / mL.

[0072] Precisely measure 0.0, 0.5, 1.0, 2.0, 3.0, 4.0ml of rutin standard solution (96.0μg / ml) and place them in calibrated 10ml test tubes, then add 0.3ml of 5% NaNO 2 , shake well, let stand for 6min. Then add 0.3ml10%Al(NO 3 ) 3 , shake well, let stand for 6min, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com