Preparation method and application of hydrophilic chromatographic stationary phase of cationic polysaccharide coating type

A cationic polysaccharide and hydrophilic chromatography technology, which is applied in the field of preparation of cationic polysaccharide-coated hydrophilic chromatography stationary phase, can solve the problems of affecting yield and cumbersome steps, and achieve high conversion rate, simple and easy-to-control process, and excellent reaction conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 350ml of anhydrous toluene and 23.8mL of γ-triethoxypropylmercaptosilane into a 500ml three-neck flask, heat and stir in an oil bath at 110°C, and carry out nitrogen reflux protection. Then add a particle size of 5 μm and a pore size of The specific surface area is 100m 2 g -1 20g of spherical silica particles, reacted at 110°C for 24 hours, and finished the reaction with 4 # The sand core funnel was suction filtered, washed with toluene, acetone, water and methanol in sequence, drained and dried overnight in an oven at 80°C. Next, 200 mL of 30% hydrogen peroxide solution and 60 mL of methanol solution containing 1 mL of sulfuric acid were added to the reaction intermediate product, stirred slowly at room temperature for 20 hours, washed with water and methanol, and dried to obtain sulfonated silica gel. Elemental analysis results: C1.47%, N0%, H0.78%. Add sulfonated silica gel to 1% cationic cellulose solution, the feeding ratio is 10:1, stir at room temperatu...

Embodiment 2

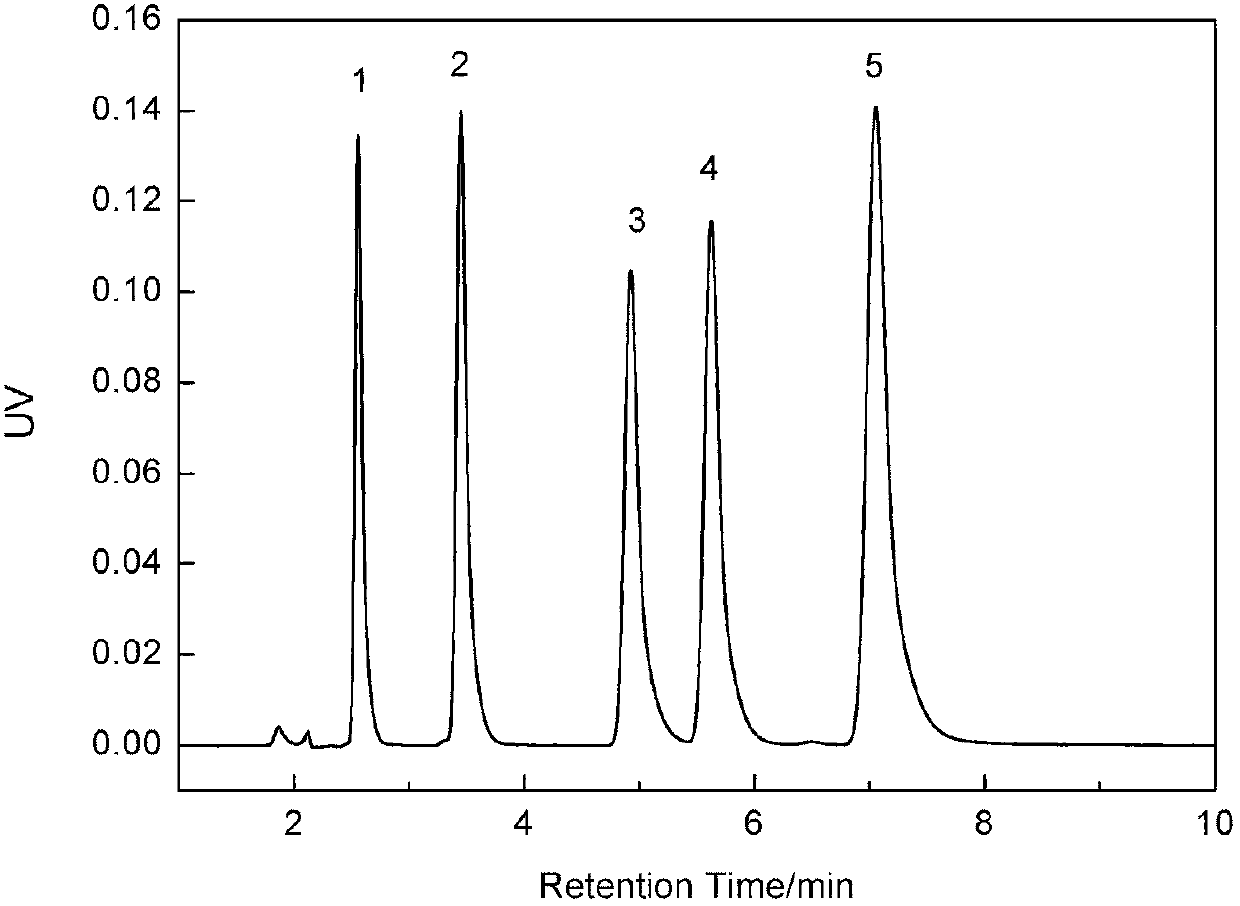

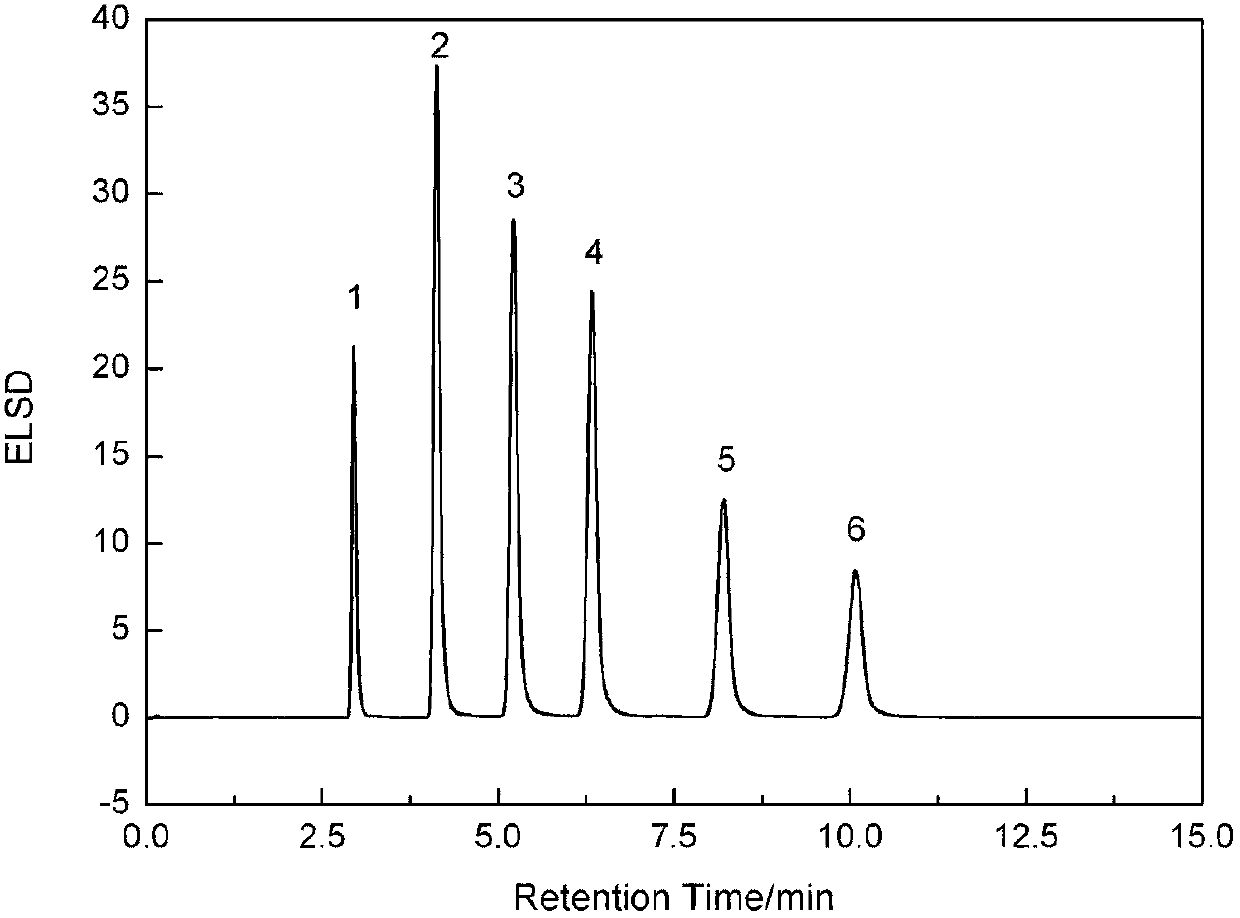

[0042] The chromatographic column prepared in Example 1 was used to separate sugars and sugar alcohols in the mode of hydrophilic interaction chromatography. With acetonitrile / water as the mobile phase, the volume ratio of acetonitrile and water is 80 / 20, sugar and sugar alcohols have been well separated, as shown in figure 2Shown (1 is ribose, 2 is mannitol, 3 is sucrose, 4 is maltitol, 5 is raffinose, 6 is melezitose).

Embodiment 3

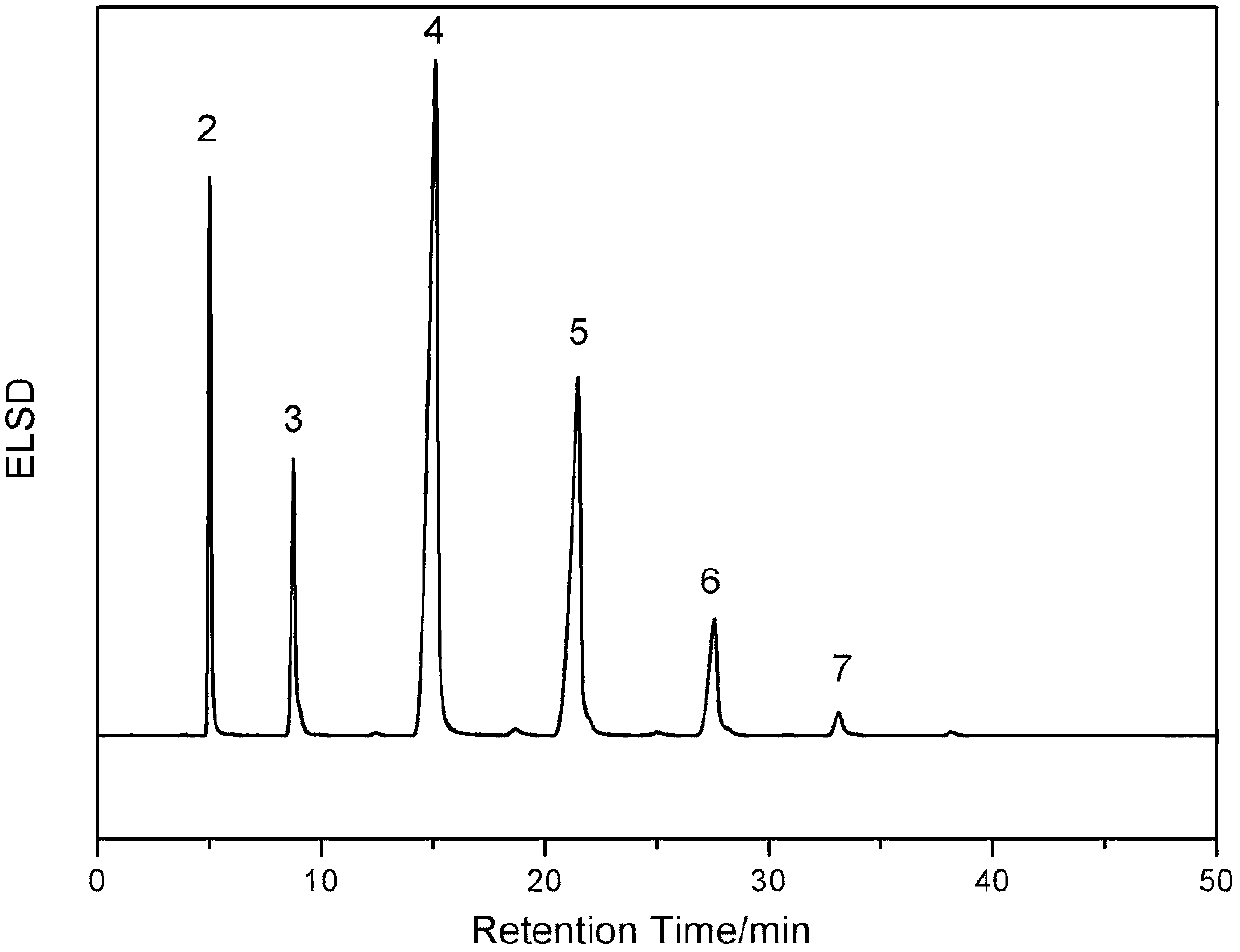

[0044] The chromatographic column prepared in Example 1 was used to separate the galactooligosaccharide sample in the mode of hydrophilic interaction chromatography. Using acetonitrile / water as the mobile phase and gradient elution (water volume content: 0-60 minutes: 20-40%), the galactooligosaccharide sample was well retained and separated, such as image 3 As shown, (2 to 7 in the figure represent di-to-heptasaccharides with different degrees of polymerization respectively).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com