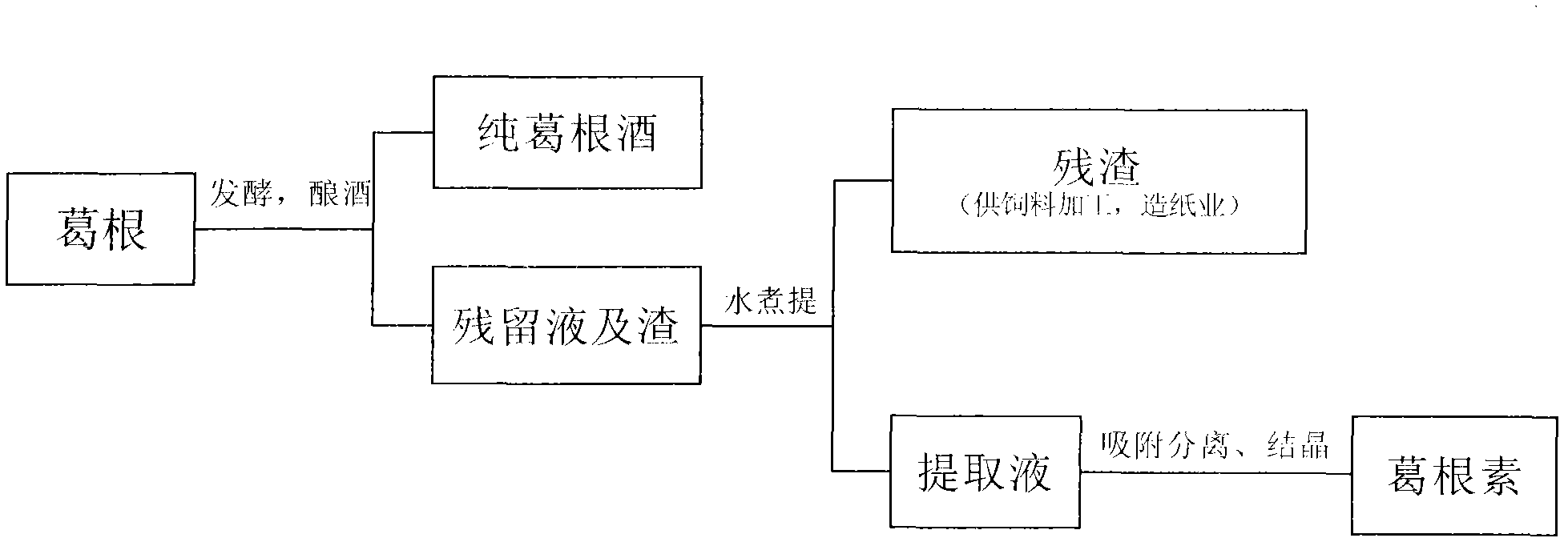

Kudzuvine root comprehensive processing and utilization scheme

A technology of comprehensive processing and scheme, applied in the field of comprehensive processing and utilization of kudzu root, can solve the problems of waste of resources and low utilization rate of kudzu root processing, and achieve the effects of avoiding potential safety hazards, saving grain, and reducing extraction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 100Kg of powdered kudzu root dry block (puerarin content 1.3%), steamed, fed according to the ratio of kudzu root raw material: distiller’s yeast: water 100:0.8:260, adjust PH6, when adding distiller’s yeast, the water temperature is controlled at 25-28°C, and the feed liquid is stirred Evenly sealed and fermented for 12 days, the wine was distilled to obtain 28 kg of 65-degree liquor.

[0019] Add 300kg of water to the residue after drinking, decoct and extract twice, and combine the extracts. Flow the extract through 120kg ADS-8 resin, the adsorption flow rate is controlled at 1.2-2.5BV / hr; wash with 3BV of water to remove impurities, and then elute puerarin with 3BV of 20% ethanol, the desorption flow rate is 1-1.5BV / hr. After recovering ethanol from the desorption solution, the residue was recrystallized with 80-90% glacial acetic acid to obtain 0.82 kg of crystalline puerarin, which was 97% as detected by HPLC. The dry weight of kudzu root residue is 61kg, which c...

Embodiment 2

[0021] Pueraria mirifica dry slices 100Kg (puerarin content 2.5%), steamed, feed according to Pueraria raw material: distiller’s yeast: water ratio of 100:1:260, adjust PH6, control water temperature at 25-28°C when adding distiller’s yeast, stir the feed liquid Evenly sealed and fermented for 15 days, the wine was distilled to obtain 20 kg of 65-degree liquor.

[0022] Add 300kg of water to the residue after drinking, decoct and extract twice, and combine the extracts. Flow the extract through 120kg AB-8 resin, the adsorption flow rate is controlled at 1.2-2.5BV / hr; after washing with 3BV of water to remove impurities, then elute puerarin with 3BV of 20% ethanol, the desorption flow rate is 1-1.5BV / hr. After recovering ethanol from the desorption solution, the residue was recrystallized with 80-90% glacial acetic acid to obtain 1.52 kg of crystalline puerarin, which was 97.2% as detected by HPLC. The dry weight of kudzu root residue is 67kg, which can be used in feed industr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com