Preparation method of asymmetric rare earth capacitor battery

A capacitive battery, asymmetric technology, applied in the direction of electrode manufacturing, fuel cell integration, circuits, etc., can solve the problems of difficulty in improving production efficiency, affecting welding quality, and increasing loss rate, so as to improve production efficiency, improve battery consistency, The effect of low cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

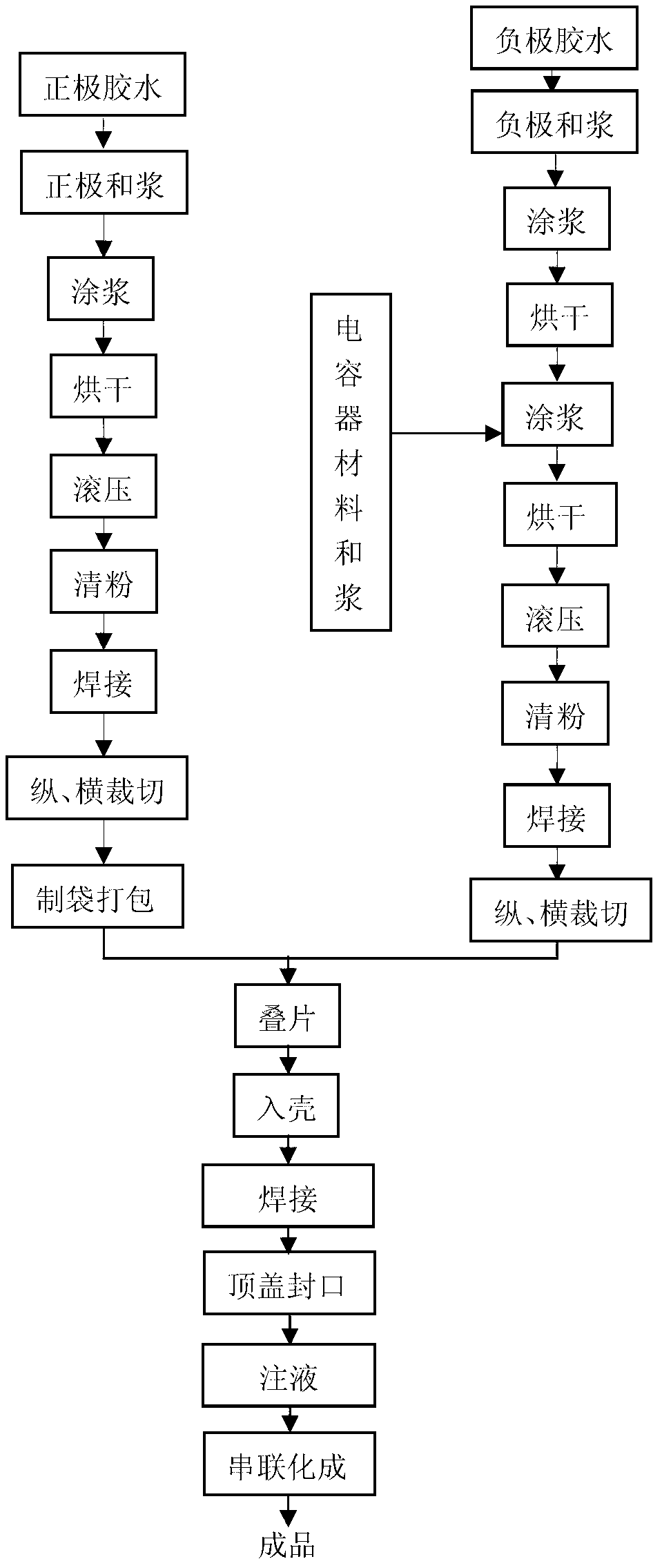

[0056] It consists of four parts: preparation of slurry, integrated preparation of positive and negative electrodes, battery assembly and series connection of batteries, such as image 3 As shown, specifically:

[0057] a. Preparation of positive and negative electrode battery slurry and capacitor slurry:

[0058] Preparation of positive battery slurry: according to 5%wtCMC, 10%wtPTFE, 85%wt H 2 O mixed evenly, put on hold for 18h to make positive electrode glue; by weight 100%wt, get 70%wt yttrium-doped spherical nickel hydroxide, 3%wt cobalt powder, 1%wt yttrium oxide, 15%wt positive electrode glue, 11%wt h 2 O mixed evenly to prepare positive electrode slurry.

[0059] Preparation of negative battery slurry: according to 5%wt HPMC, 9%wtSBR, 86%wt H 2 O mixed evenly, put on hold for 18h to make negative electrode glue; by weight 100%wt, take 75%wt power type hydrogen storage alloy, 1.0%wt nickel powder, 1.0%wt cerium oxide, 1.0%wt ferric oxide, 10% wt negative electrode...

Embodiment 2

[0068] It consists of four parts: preparation of slurry, integrated preparation of positive and negative electrodes, battery assembly and series connection of batteries, such as image 3 As shown, specifically:

[0069] a. Preparation of positive and negative electrode battery slurry and capacitor slurry:

[0070] Preparation of positive battery slurry: according to 50%wt PTFE, 50%wt H 2 O mixed evenly, put on hold for 18h to make positive electrode glue; by weight 100%wt, get 75%wt yttrium-doped spherical nickel hydroxide, 1%wt cobalt powder, 1%wt yttrium oxide, 20%wt positive electrode glue, 3%wtH 2 O mixed evenly to prepare positive electrode slurry.

[0071] Preparation of negative battery slurry: according to 5%wt HPMC, 10%wtSBR, 5%wt PVDF, 80%wt H 2 O mixed evenly, put aside for 12h to make negative electrode glue; by weight 100%wt, take 70%wt power type hydrogen storage alloy, 1.0%wt nickel powder, 0.5%wt lanthanum oxide, 1.0%wt yttrium oxide, 0.5%wt four Ferric oxi...

Embodiment 3

[0080] It consists of four parts: preparation of slurry, integrated preparation of positive and negative electrodes, battery assembly and series connection of batteries, such as image 3 Shown, specifically: a, prepare positive and negative electrode battery slurry and capacitor slurry:

[0081] Preparation of positive battery slurry: according to 4%wt CMC, 10%wt PVA, 1%wt PTFE, 85%wt H 2 O mixed evenly, put on hold for 36h to make positive electrode glue; by weight 100%wt, take 75%wt yttrium-doped cobalt-coated spherical nickel hydroxide, 1%wt cobaltous oxide, 2%wt cobalt oxyhydroxide, 1%wt zinc oxide , 15%wt positive glue, 6%wt H 2 O mixed evenly to prepare positive electrode slurry.

[0082] Preparation of negative battery slurry: according to 3%wt HPMC, 3%wtSBR, 4%wt PTFE, 90%wt H 2 O mixed evenly, put aside for 24h to make negative electrode glue; by weight 100%wt, take 68%wt power type hydrogen storage alloy, 0.5%wt nickel powder, 0.5%wt ytterbium oxide, 1.0%wt yttriu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com