Tissue engineering scaffold with multi-growth-factor sequential release characteristic

A tissue engineering scaffold and growth factor technology, applied in medical science, prosthesis, etc., can solve the problems of difficulty in introducing growth factors, harsh preparation process conditions, organic solvent residues, etc., and achieves simple operation, good physical and chemical properties, and low toxicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

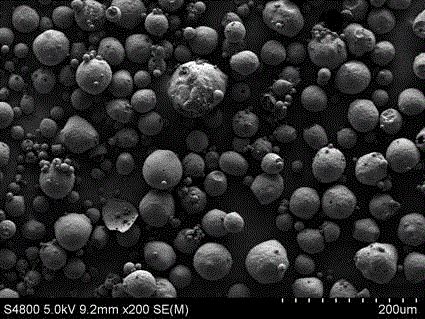

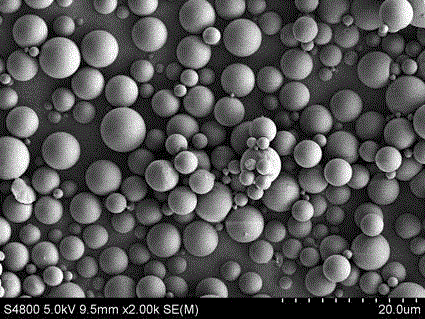

[0020] Example 1 Preparation of BMP-2-PLLA, VEGF-PLLA and bFGF-PLLA drug-loaded microspheres

[0021] (1) Dissolve 10 μg of BMP-2, VEGF and bFGF in 250 uL PBS as the inner aqueous phase.

[0022] (2) Weigh 250 mg of PLLA (molecular weight 1-100,000) and polyethylene glycol (PEG, molecular weight 400-10,000), the mass ratio of PLLA to PEG is 1:2-2:1, dissolve in 5 mL Dichloromethane was used as the oil phase (the volume ratio of the inner water phase to the oil phase was 1:20).

[0023] (3) Slowly pour the inner water phase into the oil phase and stir at high speed for 2 minutes to form colostrum (W / O).

[0024] (4) Slowly drop colostrum into 10 mL of 1 % PVA, stir at high speed for 5 minutes to form double milk (WO / W).

[0025] (5) Slowly drop double emulsion into 250mL, 0.1% PVA, stir at room temperature for 4 hours, 500 r / min, for volatile organic solvent.

[0026] (6) Centrifuge at 4000 r / min for 10 minutes to collect microspheres, wash with deionized water three times, ...

example 2

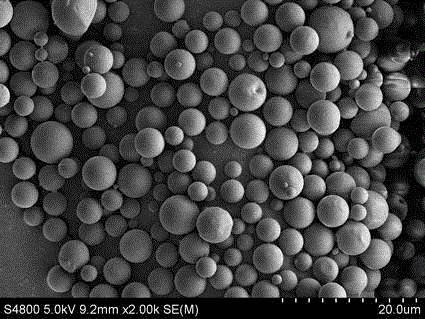

[0029] Example 2 Preparation of HA / PLGA porous scaffold containing trypsin sustained-release microspheres

[0030] (1) PLGA to be purchased (PLA:PLG=50:50, M W =100,000Da) and HA powder at a ratio of 1:4 for grinding for 8 hours, then add 10% trypsin slow-release microspheres and mix well with the powder.

[0031] (2) Accurately weigh 0.125g of the mixed powder and put it into a cylindrical mold with a diameter of 5mm for pressing. The pressure is 10MPa and the pressing time is 1min to obtain a small disc with a diameter of 5mm and a height of about 3mm. In the tetrafluoroethylene mold customized by the laboratory.

[0032](3) Put the tetrafluoroethylene mold into the autoclave, turn on the supercritical foaming device, the refrigeration system starts to work, set the reaction temperature to 39°C, and the pressure to 8Mpa, turn on the high-pressure plunger pump, constant temperature water bath box and drum drying box, the reaction kettle is boosted and heated. Adjust the ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com