Silicon resin modified unsaturated polyester resin and preparation method thereof

A technology of polyester resin and silicone resin, applied in the field of silicone resin modified unsaturated polyester resin and preparation of the resin, can solve the problems of reducing material strength and heat resistance, increasing production process, increasing production cost, etc., and achieving hardness The effect of maintaining, low cost and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

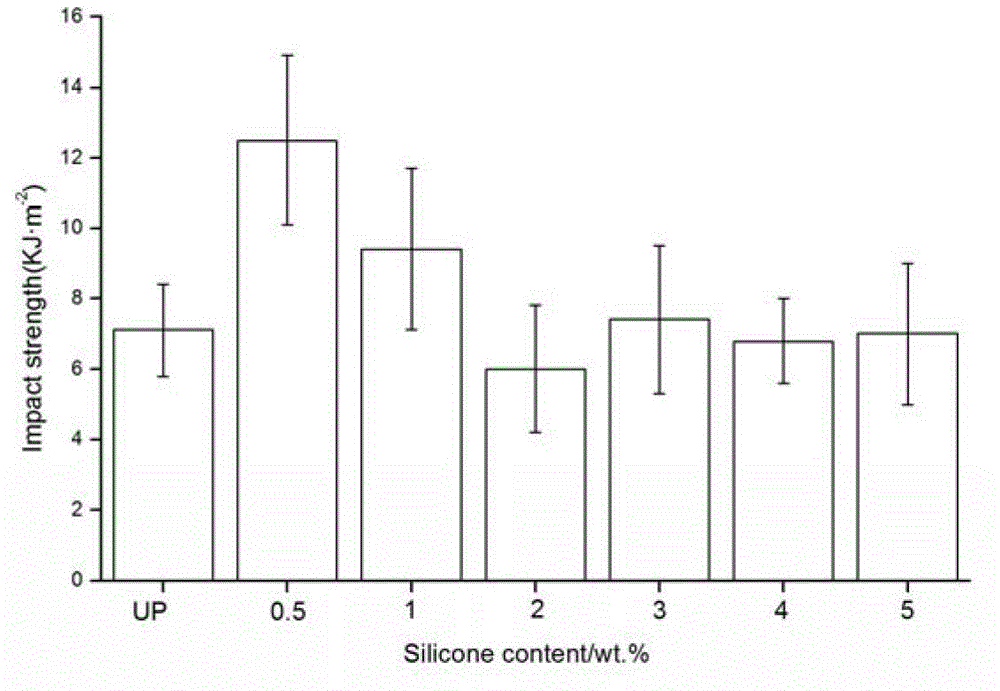

[0030] Embodiment 2 (0.5wt.% silicone resin modification)

[0031] Keep the molar ratio of maleic anhydride to phthalic anhydride at about 4:5 (maleic anhydride 197g, phthalic anhydride 371.5g); the molar ratio of diethylene glycol, ethylene glycol and propylene glycol is about 1:3:9 (diethylene glycol 42g, ethylene glycol 67g, propylene glycol 262g), the content of silicone resin with silanol groups (commercially available, preferably Dow Corning Z-6018) accounts for 0.5% of the total mass of the resin (6.25g). Stir the silicone resin and three diol monomers mechanically under a nitrogen atmosphere at 180°C and a small amount of catalyst (10 drops of butyl orthotitanate) for more than 3 hours, then cool to room temperature; Under mechanical stirring, react at 165-205°C for 6 hours, then react under vacuum for 2 hours until the acid value of the system is reduced to about 30mgKOH / g, add additives (0.6g triphenyl phosphite and 0.015g hydroquinone) and 370g styrene (pre-added ...

Embodiment 3(1

[0033] Embodiment 3 (1wt.% silicone resin modification)

[0034] Keep the molar ratio of maleic anhydride to phthalic anhydride at about 4:5 (maleic anhydride 197g, phthalic anhydride 371.5g); the molar ratio of diethylene glycol, ethylene glycol and propylene glycol is about 1:3:9 (diethylene glycol 42g, ethylene glycol 67g, propylene glycol 262g), the content of silicone resin with silanol groups (commercially available, preferably Dow Corning Z-6018) accounts for 1% of the total mass of the resin (12.5g. Stir the silicone resin and three diol monomers mechanically under a nitrogen atmosphere at 180°C and a small amount of catalyst for more than 3 hours, then cool to room temperature; add an acid anhydride to the reaction bottle, and under a nitrogen atmosphere and mechanical stirring, React in the range of 165-205°C for 6 hours, then react under vacuum for 2 hours until the acid value of the system is reduced to about 30mgKOH / g, add additives (0.6g triphenyl phosphite and 0...

Embodiment 4(2

[0036] Embodiment 4 (2wt.% silicone resin modification)

[0037] Keep the molar ratio of maleic anhydride to phthalic anhydride at about 4:5 (maleic anhydride 197g, phthalic anhydride 371.5g); the molar ratio of diethylene glycol, ethylene glycol and propylene glycol is about 1:3:9 (diethylene glycol 42g, ethylene glycol 67g, propylene glycol 262g), the content of silicone resin with silanol groups (commercially available, preferably Dow Corning Z-6018) accounts for 2% of the total mass of the resin (25g). Stir the silicone resin and three diol monomers mechanically under a nitrogen atmosphere at 180°C and a small amount of catalyst for more than 3 hours, then cool to room temperature; React in the range of ℃ for 6 hours, then react under vacuum for 2 hours until the acid value of the system is reduced to about 30mgKOH / g, add additives (0.6g triphenyl phosphite and 0.015g hydroquinone) and 370g of styrene (pre-added 0.19mL 1% copper naphthenate solution) was diluted to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com