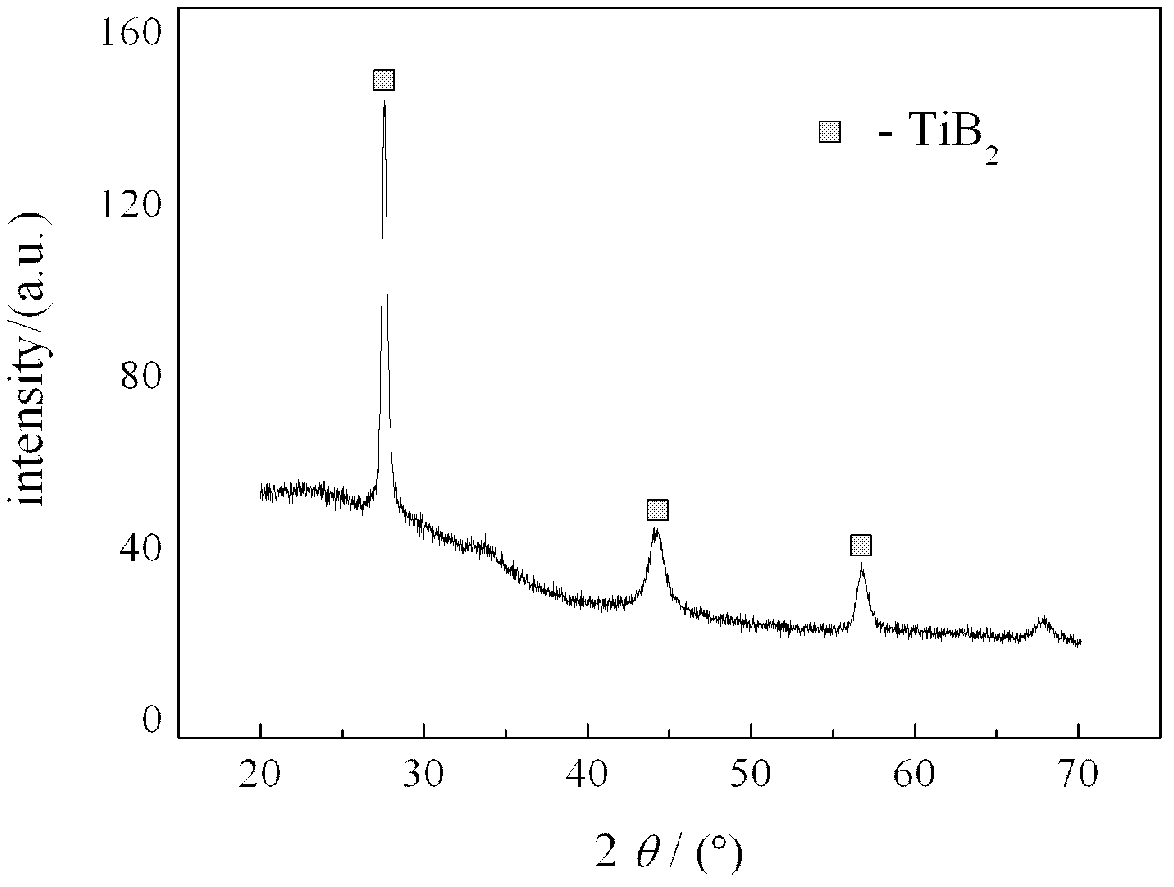

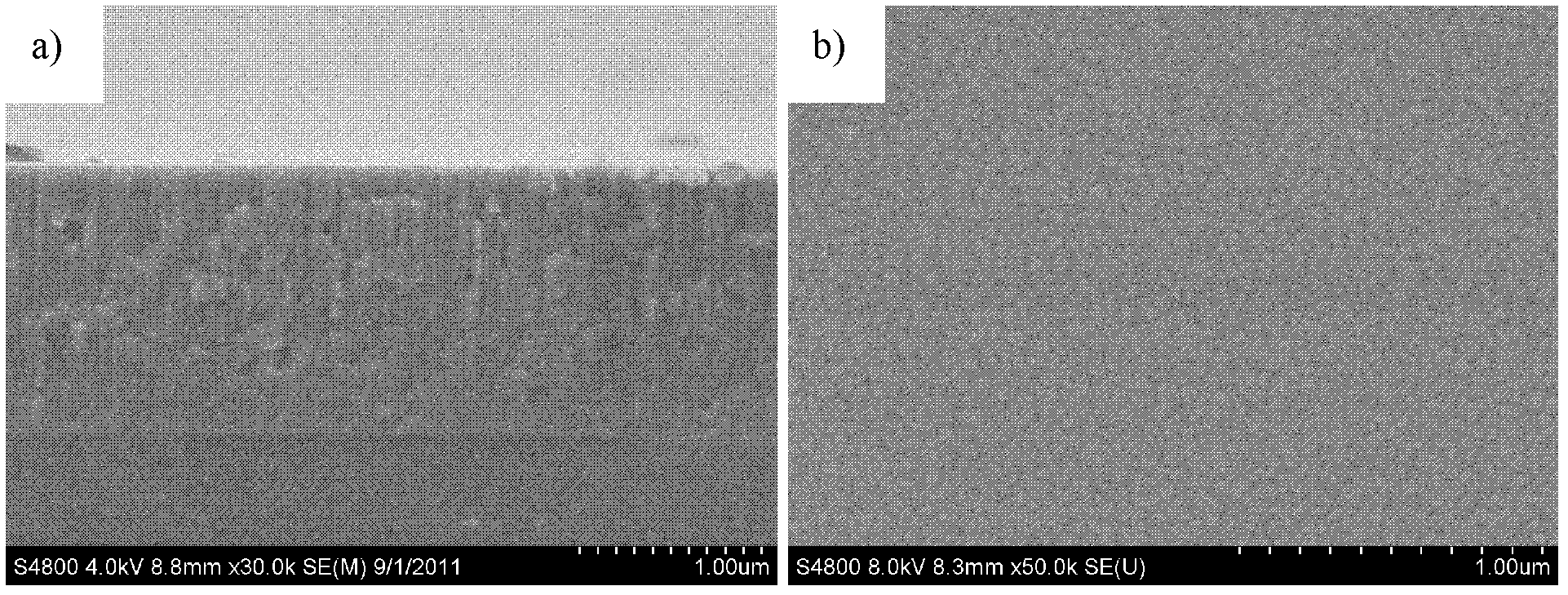

Titanium diboride-nickel coating or film and preparation method thereof

A titanium diboride and nickel coating technology, which is applied in the coating, metal material coating process, ion implantation plating, etc., to achieve the effect of convenient operation, low cost and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Select commercially available TiB with a purity of 99.9% 2 A ceramic target and a commercially available metal Ni target with a purity of 99.99% are used as raw materials; a (100)-oriented single crystal silicon substrate is selected as a substrate.

[0027] 2) Firstly, the substrate is cleaned, and the substrate is ultrasonically cleaned with absolute ethanol, acetone, and absolute ethanol for 20 minutes in sequence, and then dried at 80° C. for 2 hours by blasting, and then set aside.

[0028] 3) Using the magnetron sputtering system independently designed and produced by our research group, first open the cavity and install the substrate and target correctly, first check that the gas, electricity, and water circuits are normal, then turn on the main power supply and start the mechanical pump, when the deposition chamber and the sample After the air pressure in the chamber is below 10Pa, close the valve between the mechanical pump and the chamber, open the baffle v...

Embodiment 2

[0035] 1) Select commercially available TiB with a purity of 99.9% 2 A ceramic target and a commercially available metal Ni target with a purity of 99.99% are used as raw materials; a common flat glass substrate is used as a substrate.

[0036] 2) Firstly, the substrate is cleaned, and the substrate is ultrasonically cleaned with absolute ethanol, acetone, and absolute ethanol for 20 minutes in sequence, and then dried at 80° C. for 2 hours by blasting, and then set aside.

[0037] 3) Using the magnetron sputtering system independently designed and produced by our research group, first open the cavity and install the substrate and target correctly, first check that the gas, electricity, and water circuits are normal, then turn on the main power supply and start the mechanical pump, when the deposition chamber and the sample After the air pressure in the chamber is below 10Pa, close the valve between the mechanical pump and the chamber, open the baffle valve, start the molecula...

Embodiment 3

[0043] 1) Select commercially available TiB with a purity of 99.9% 2 A ceramic target and a commercially available metal Ni target with a purity of 99.99% are used as raw materials; the substrate is a high-speed steel substrate.

[0044] 2) Firstly, the substrate is cleaned, and the substrate is ultrasonically cleaned with absolute ethanol, acetone, and absolute ethanol for 20 minutes in sequence, and then dried at 80° C. for 2 hours by blasting, and then set aside.

[0045] 3) Using the magnetron sputtering system independently designed and produced by our research group, first open the cavity and install the substrate and target correctly, first check that the gas, electricity, and water circuits are normal, then turn on the main power supply and start the mechanical pump, when the deposition chamber and the sample After the air pressure in the chamber is below 10Pa, close the valve between the mechanical pump and the chamber, open the baffle valve, start the molecular pump,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com