Method of preparing biology activity composite thin film on surface of titanium alloy

A bioactive, composite film technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of less research on surface biological protein adhesion, achieve excellent tribological properties and biological activity, excellent Tribological properties, the effect of simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

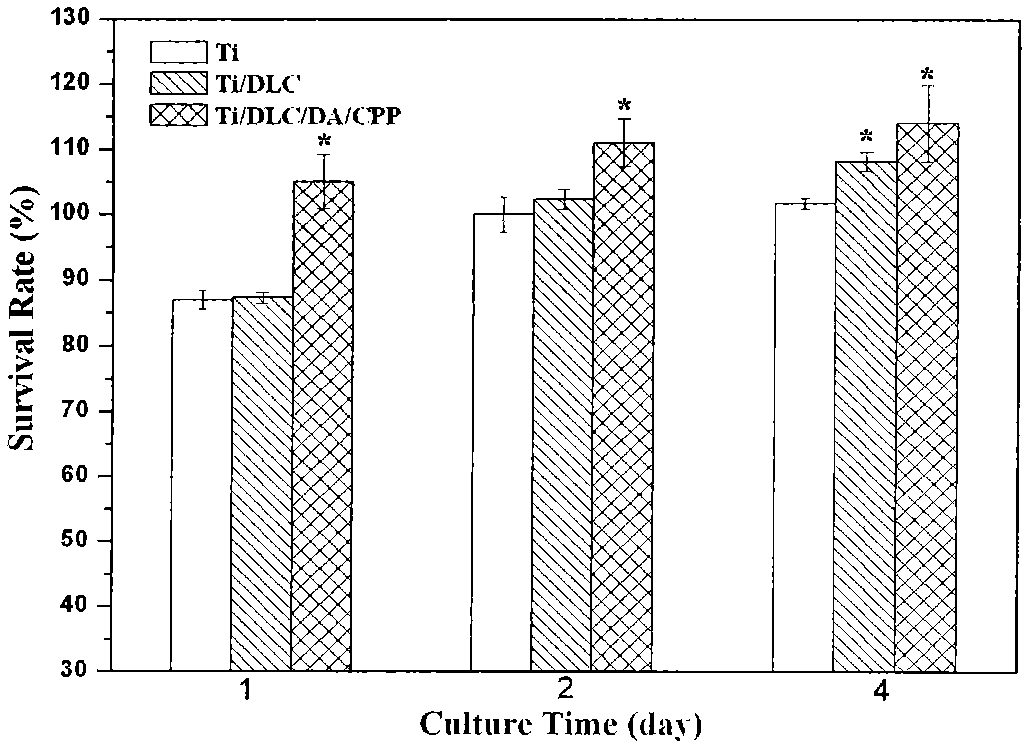

Image

Examples

Embodiment 1

[0019] Take 1×1cm 2 Large and small Ti-6Al-4V slices, the structure of DLC / CPP bioactive composite film on the surface of Ti-6Al-4V slices is Ti-6Al-4V matrix / DLC layer / CPP layer, and the treatment process is carried out according to the following steps: (1) Ti- The 6Al-4V substrate was cleaned by conventional degreasing, followed by ultrasonic cleaning in acetone and ethanol solutions; (2) The Ti-6Al-4V substrate was placed in a multi-arc ion plating-magnetron sputtering composite vapor deposition vacuum system , carry out argon plasma sputtering cleaning, the flow rate of argon gas is 500sccm, the bias voltage is 1.3KV, the target current is 12A, and the processing time is 15min; The gas is argon, the flow rate is 70 sccm, the bias voltage is 800V, and the processing time is 5-10 minutes; (3) the multi-arc ion plating deposits DLC, the working gas is methane, the flow rate is 200 sccm, the bias voltage is 800V, the duty ratio is 80%, and the processing time is The time is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com