Method for extracting kidney bean starch and coproducing kidney bean protein powder and dietary fiber powder

A technology of dietary fiber powder and dietary fiber, applied in protein food ingredients, protein composition of vegetable seeds, food preparation, etc., can solve the problems of short industrialization chain of kidney bean resource processing and easy pollution of production environment, and achieve value-added and high efficiency , Significant economic benefits, promote the effect of depolymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

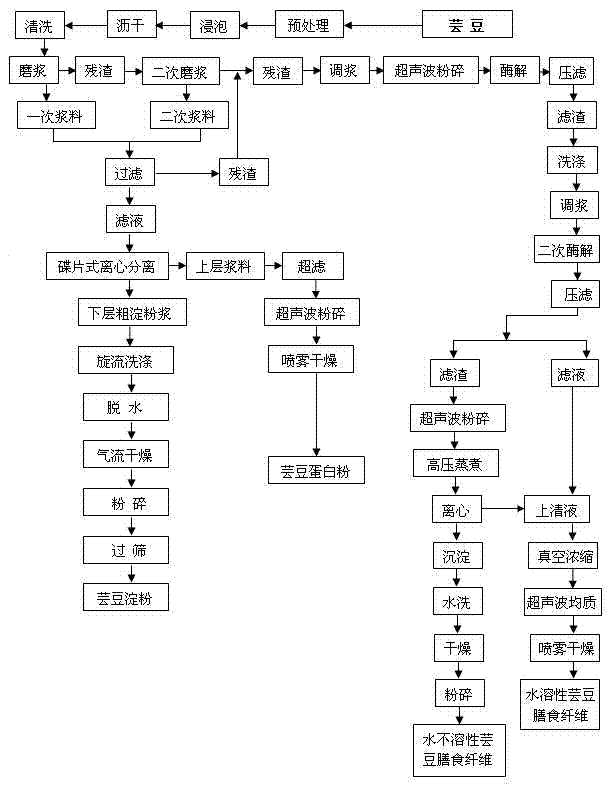

[0046] Such as figure 1 As shown, the method of extracting kidney bean starch and co-producing kidney bean protein powder and dietary fiber powder is as follows,

[0047] Weigh 100Kg of red kidney beans after selection and removal of impurities, soak in 300L sodium bisulfite solution with a concentration of 0.2% at 20°C for 24 hours, remove and place in 300L of clean water, stir and wash thoroughly for 10 minutes, remove Drain. Then add the washed kidney beans into 400L of clear water, soak at room temperature for 20 minutes, and use a built-in screen with the function of self-separation of pulp and residue to refine pulp with a 100-mesh refiner to obtain a primary slurry. Add the residue to 400L of clear water for secondary refining, separate the slurry to obtain secondary slurry and wet residue, combine the primary and secondary slurry to obtain a mixed slurry, and pass through a 200-mesh sieve to obtain the undersize fine slurry for use in Kidney bean starch and kidney be...

Embodiment 2

[0052] The method of extracting kidney bean starch and co-producing kidney bean protein powder and dietary fiber powder is as follows,

[0053] Weigh 100Kg of white kidney beans after selection and removal of impurities, soak in 300L sodium bisulfite solution with a concentration of 0.1% at 45°C for 12 hours, remove and place in 300L of clean water, stir and wash thoroughly for 10 minutes, remove Drain. Then add the washed kidney beans into 400L of clear water, soak at room temperature for 20 minutes, and use a built-in screen with the function of self-separation of pulp and residue to refine pulp with a 100-mesh refiner to obtain a primary slurry. Add the residue to 400L of clear water for secondary refining, separate the slurry to obtain secondary slurry and wet residue, combine the primary and secondary slurry to obtain a mixed slurry, and pass through a 200-mesh sieve to obtain the undersize fine slurry for use in Kidney bean starch and kidney bean protein extraction; the...

Embodiment 3

[0058] The method of extracting kidney bean starch and co-producing kidney bean protein powder and dietary fiber powder is as follows,

[0059] Weigh 100Kg of black kidney beans after selection and removal of impurities, soak in 300L sodium bisulfite solution with a concentration of 0.15% at 35°C for 16 hours, remove and place in 300L of clean water, stir and wash thoroughly for 10 minutes, remove Drain. Then add the washed kidney beans into 400L of clear water, soak at room temperature for 20 minutes, and use a built-in screen with the function of self-separation of pulp and residue to refine pulp with a 100-mesh refiner to obtain a primary slurry. Add the residue to 400L of clear water for secondary refining, separate the slurry to obtain secondary slurry and wet residue, combine the primary and secondary slurry to obtain a mixed slurry, and pass through a 200-mesh sieve to obtain the undersize fine slurry for use in Kidney bean starch and kidney bean protein extraction; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com