Method for preparing binary oxide modified diatomite powder through recycled waste WC-TiC (wolfram carbide-titanium carbide) alloy

A binary oxide, diatomite technology, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., to achieve the effect of simplifying the preparation process, excellent photodegradation and adsorption performance, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

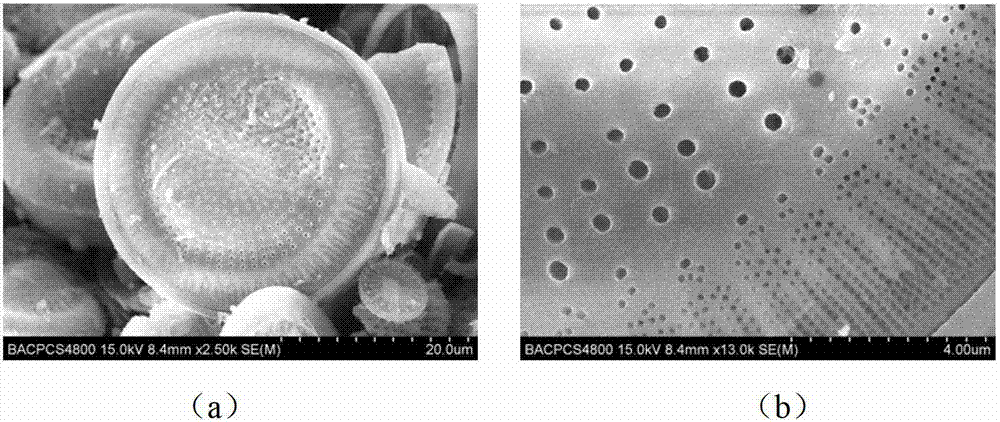

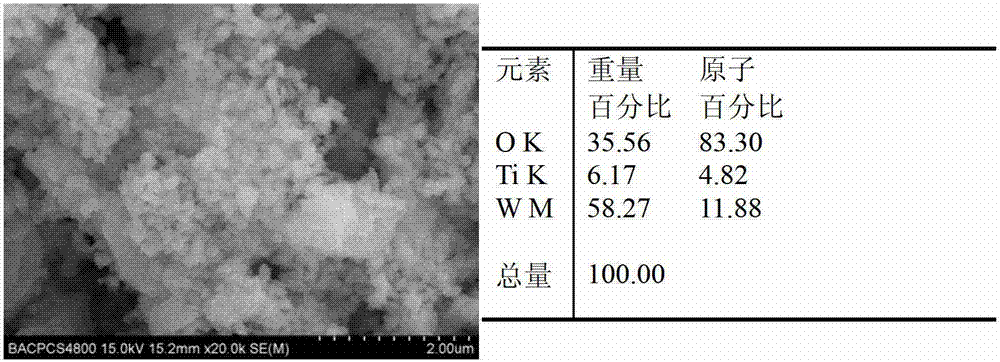

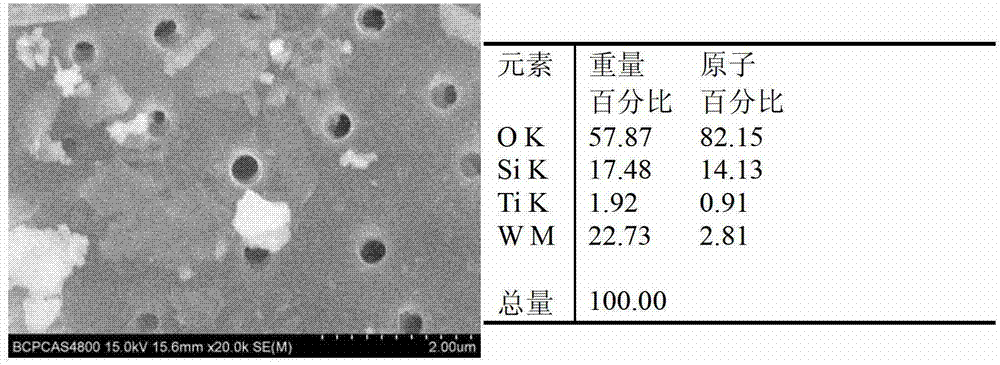

[0024] Take the pretreated waste WC-TiC alloy block and put it into a hydrothermal kettle, add 10ml of 16M concentrated nitric acid, 10ml of 30% hydrogen peroxide, and 0.5ml of hydrofluoric acid, and put it in an air-tight drying oven at 170°C for 24h. After the reaction, the precipitated powder was filtered out, rinsed with deionized water and ethanol until neutral, and dried to obtain WO 3 -TiO 2 Nanocomposite particles, reserved for future use. Take 10g of diatomite and add it to 10% 300ml hydrochloric acid solution, wash and stir it with deionized water until it becomes neutral, dry and calcinate it, then cool down with the furnace, and keep it for later use. WO 3 -TiO 2 Add 1 g of nanocomposite nanopowder, 2 g of diatomaceous earth, and 1 ml of silane coupling agent into the aqueous solution for ultrasonic impregnation for 12 hours. After drying the impregnated diatomite powder, put it into a muffle furnace for calcination at 500°C for 2 hours, and keep it for later u...

Embodiment 2

[0026] Take the pretreated waste WC-TiC alloy block and put it into a hydrothermal kettle, add 10ml of 16M concentrated nitric acid, 10ml of 30% hydrogen peroxide, and 1ml of hydrofluoric acid, and put it in a forced air drying oven for 24 hours at 170°C. After the reaction, the precipitated powder was filtered out, rinsed with deionized water and ethanol until neutral, and dried to obtain WO 3 -TiO 2 Nanocomposite particles, reserved for future use. Take 10g of diatomite and add it to 10% 300ml hydrochloric acid solution, wash and stir it with deionized water until it becomes neutral, dry and calcinate it, then cool down with the furnace, and keep it for later use. WO 3 -TiO 2 Add 1 g of nanocomposite nanopowder, 1 g of diatomaceous earth, and 1 ml of silane coupling agent into the aqueous solution for ultrasonic impregnation, and ultrasonic for 12 hours. After drying the impregnated diatomite powder, put it into a muffle furnace for calcination at 500°C for 2 hours, and ...

Embodiment 3

[0028] Take the pretreated waste WC-TiC alloy block and put it into a hydrothermal kettle, add 10ml of 16M concentrated nitric acid, 10ml of 30% hydrogen peroxide, and 2ml of hydrofluoric acid, and put it in a forced air drying oven at 160°C for 24h. After the reaction, the precipitated powder was filtered out, rinsed with deionized water and ethanol until neutral, and dried to obtain WO 3 -TiO 2Nanocomposite particles, reserved for future use. Take 10g of diatomite and add it to 10% 300ml hydrochloric acid solution, wash and stir it with deionized water until it becomes neutral, dry and calcinate it, then cool down with the furnace, and keep it for later use. WO 3 -TiO 2 Add 1 g of nanocomposite nanopowder, 0.5 g of diatomaceous earth, and 0.5 ml of silane coupling agent into the aqueous solution for ultrasonic impregnation, and ultrasonic for 12 hours. After drying the impregnated diatomite powder, put it into a muffle furnace for calcination at 400°C for 1 hour, and kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com