Process for producing basic copper chloride by using berberine copper-containing wastewater

A technology of berberine and copper chloride, applied in the direction of copper chloride, copper halide, etc., to achieve the effect of simple process route, low content of harmful impurities and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

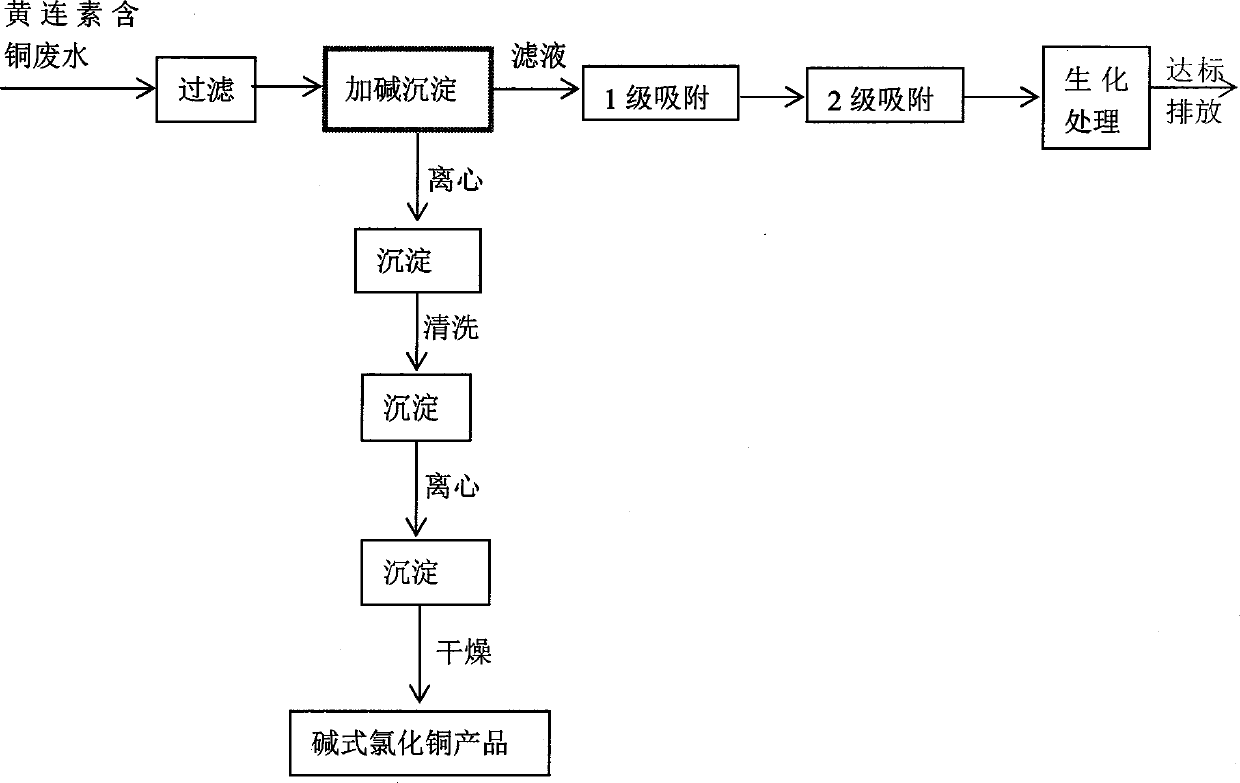

Image

Examples

Embodiment 1

[0033] A kind of preparation method of basic cupric chloride of the present invention, comprises the following steps: get 200ml berberine waste water to pass through 0.45 μ m filter membrane filter, filtrate is added reactor, open agitator, add 400g / L berberine gradually in reactor Sodium hydroxide solution is reacted, and the reaction temperature is normal temperature. As the reaction progresses, the pH value of the reaction solution rises, and basic copper chloride precipitates in the solution. When the pH value of the reaction solution rises to 7.20, stop adding the sodium hydroxide solution and control the reaction time for 0.5h. Centrifuge the materials discharged from the reaction system, and the centrifugal speed of the centrifuge is 3000r / min. Then the obtained solid is washed and centrifuged, and the obtained solid is dried in an oven at 180°C until the water content of the reaction product is below 0.2%, and passed through a 40-mesh sieve after drying to obtain the p...

Embodiment 2

[0036]A preparation method of basic copper chloride of the present invention comprises the following steps: taking 200ml of berberine waste water and filtering it through a 0.45 μm filter membrane, adding the filtrate to the reactor, opening the stirring device, and gradually adding 300g / L of berberine to the reactor sodium hydroxide solution, the reaction temperature is normal temperature. As the reaction progresses, the pH of the reaction solution rises, and basic copper chloride precipitates in the solution. When the pH of the reaction solution rises to 7.46, stop adding the sodium hydroxide solution and control the reaction time for 1 hour. Centrifuge the materials discharged from the reaction system, and the centrifugal speed of the centrifuge is 4000r / min. Then the obtained solid is washed and centrifuged, and the obtained solid is dried in an oven at 80°C until the water content of the reaction product is below 0.2%, and passed through a 40-mesh sieve after drying to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com