Capsule polyurethane drug controlled release body with temperature control switch, and preparation method thereof

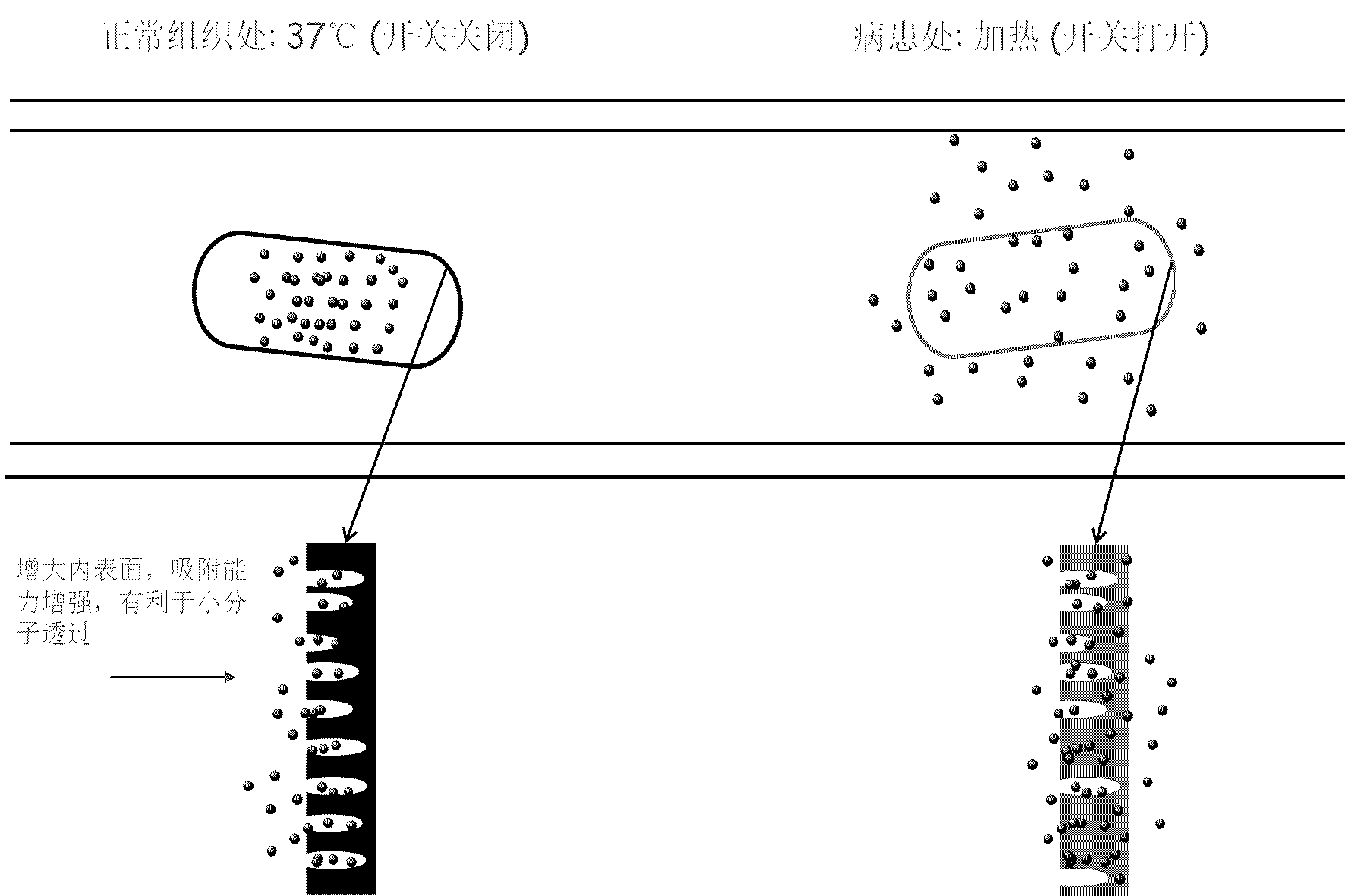

A technology of drug controlled release and temperature control switch, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc., to achieve free adjustment of drug release, fast temperature response, and repeatability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

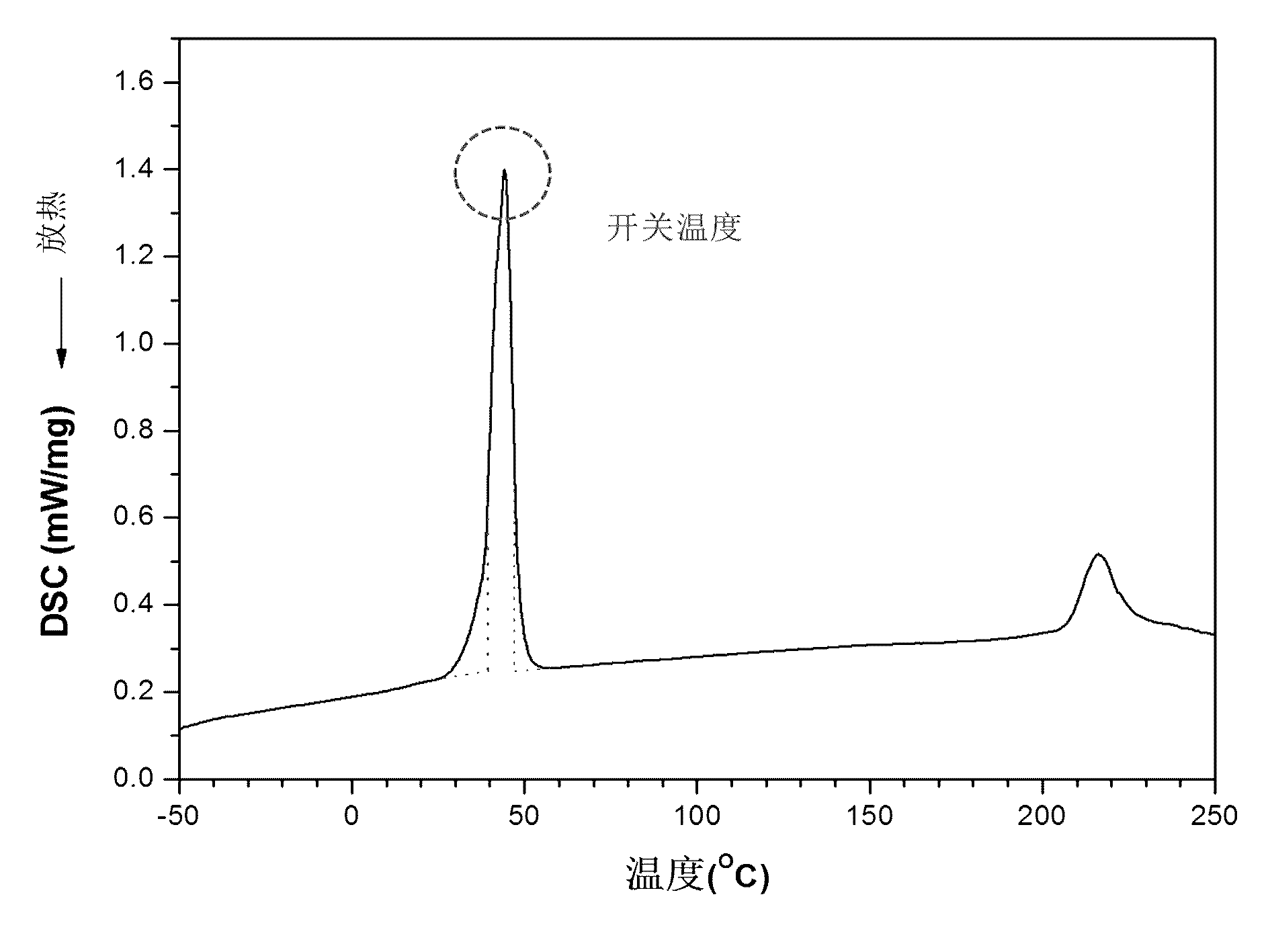

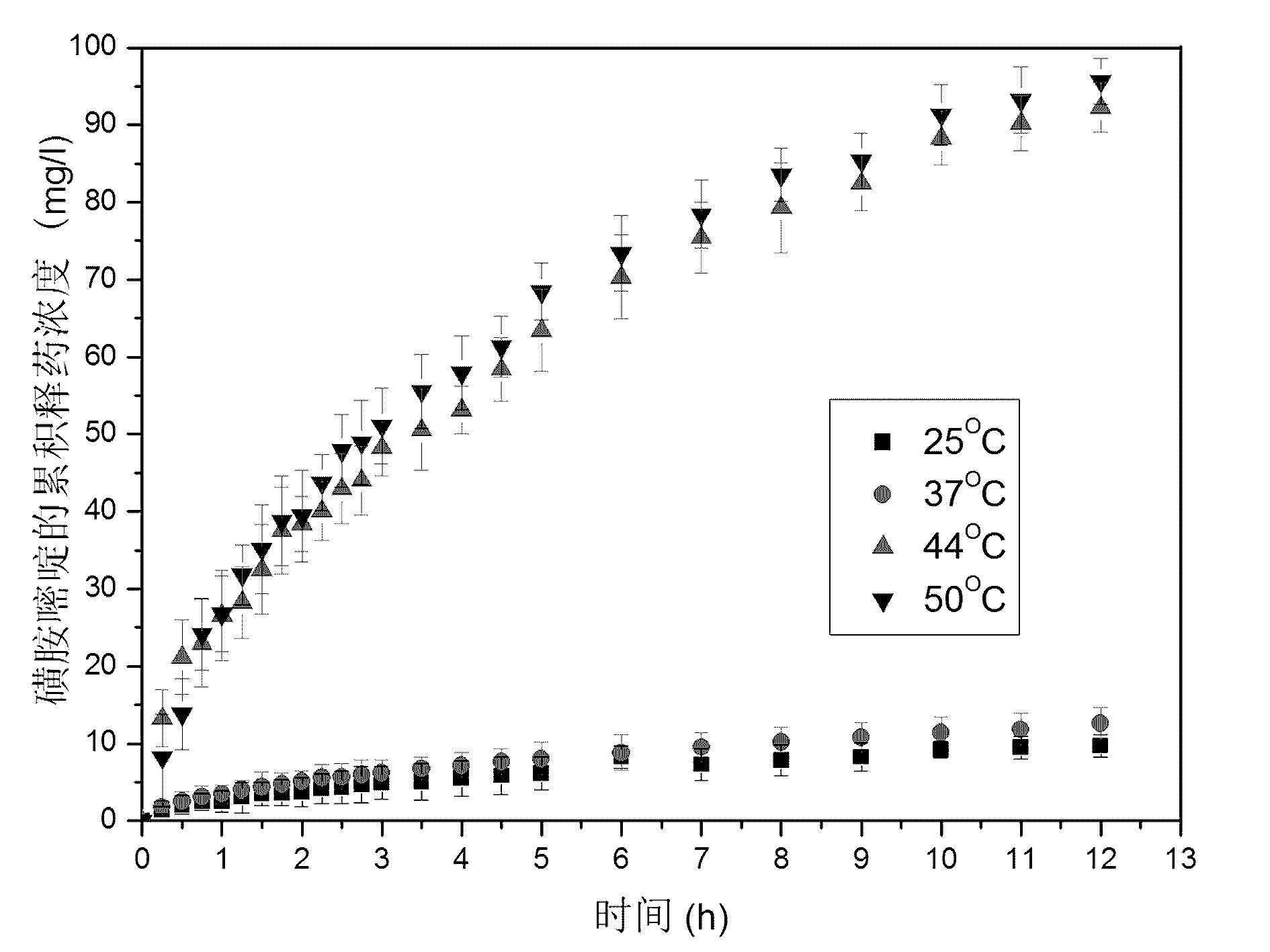

Method used

Image

Examples

Embodiment 1

[0035] (1) Add 50 parts of polycaprolactone diol with a number-average molecular weight of 4000, 15 parts of 2,4-toluene diisocyanate and 50 parts of N,N-dimethylformamide into the reaction vessel, and keep stirring and Under the protection of nitrogen atmosphere, the temperature of the system was raised to 80°C for 2.5 hours to prepare the NCO-terminated prepolymer;

[0036] (2) After the first step of reaction is completed, slowly add 6.6 parts of 1,4-butanediol chain extender and 110 parts of dimethyl sulfoxide dropwise, and maintain the reaction at 80°C for 2.3 hours to prepare a temperature-sensitive polyurethane solution;

[0037] (3) Pour the obtained temperature-sensitive polyurethane solution into a special mold to prepare a polyurethane pouch with an opening, and place it at 40-50°C until the solvent volatilizes slowly for 5-15 minutes, so that the outer wall of the pouch-shaped polyurethane is solidified and formed, which is about half The solidified temperature-se...

Embodiment 2

[0041] (1) 20 parts of polyethylene adipate diol with a number average molecular weight of 2000, 30 parts of polycarbonate diol with a number average molecular weight of 10000, 4,4'-diphenylmethane diol 19.5 parts of isocyanate and 60 parts of dimethyl sulfoxide were added to the reaction vessel, and under continuous stirring and nitrogen atmosphere protection, the system was heated to 70°C for 2.3 hours to prepare the NCO-terminated prepolymer;

[0042] (2) After the first step reaction is completed, add 5.0 parts of 1,3-propanediol chain extender and 80 parts of N,N-dimethylformamide in sequence, and maintain the reaction at 74°C for 2.5 hours to prepare a thermosensitive Polyurethane solution;

[0043] (3) Pour the obtained temperature-sensitive polyurethane solution into a special mold to prepare a polyurethane pouch with an opening, and place it at 40-50°C until the solvent volatilizes slowly for 5-15 minutes, so that the outer wall of the pouch-shaped polyurethane is sol...

Embodiment 3

[0047] (1) 15 parts of polybutylene adipate diol with a number average molecular weight of 6000, 35 parts of polycaprolactone diol with a number average molecular weight of 8000, 10 parts of 2,4-toluene diisocyanate and Add 30 parts of N,N-dimethylformamide into the reaction vessel, and raise the temperature of the system to 77°C for 2 hours under the protection of continuous stirring and nitrogen atmosphere to prepare the NCO-terminated prepolymer;

[0048] (2) After the first step reaction is completed, 6 parts of 1,6-hexanediol chain extender and 110 parts of N,N-dimethylformamide are added in sequence, and the reaction is continued at 70°C for 2 hours to prepare Thermosensitive polyurethane solution;

[0049] (3) Pour the obtained temperature-sensitive polyurethane solution into a special mold to prepare a polyurethane pouch with an opening, and place it at 40-50°C until the solvent volatilizes slowly for 5-15 minutes, so that the outer wall of the pouch-shaped polyurethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com