Saturated absorption composite material ink, preparation method and optical fiber laser based on ink

A saturable absorption, fiber laser technology, applied in the field of fiber lasers, can solve the problems of limiting the output power, stability and service life of the laser, limiting the optimization range of the pulse laser parameters, increasing the scattering loss of the saturable absorption device, etc. Operational reliability and output power stability, cost savings, and the effect of simplifying design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

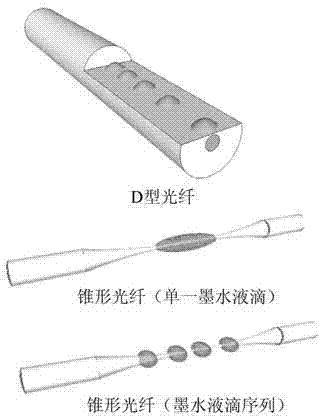

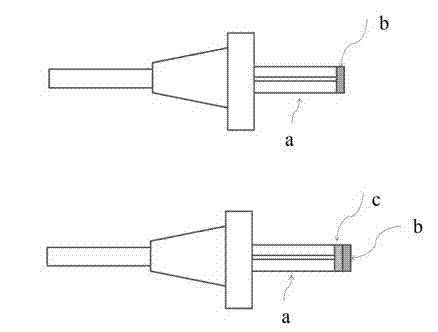

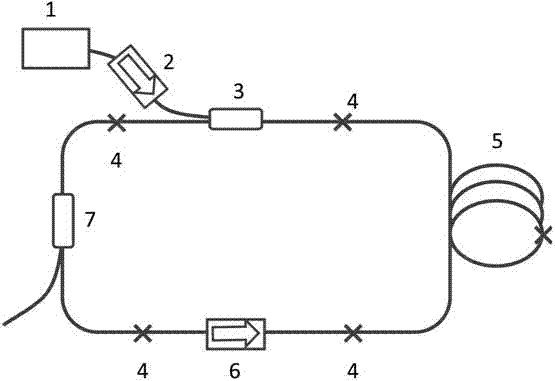

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] In one example, 5 mg of single-walled carbon nanotube (SWNTs) powder and 50 mg of sodium dodecylbenzenesulfonate (SDBS) were dissolved in 10 mL of water and dispersed by ultrasonic (power 180W, temperature 8-10 o C) Treat for 120 minutes, centrifuge the obtained carbon nanotube dispersion (25000g, temperature 14 o C), treated for 120 minutes to obtain an aqueous solution of single-walled carbon nanotubes; 80 mg of graphite powder and 60 mg of sodium deoxycholate (SDC) were dissolved in 10 mL of water, and dispersed by ultrasonic (power 180W, temperature 8-10 o C) After processing for 240 minutes, centrifuge the obtained dispersion liquid containing single-layer graphene and few-layer graphene (25000g, temperature 14 oC ), and treated for 60 minutes to obtain a graphene aqueous solution; dissolve PVA in water with a mass percentage of 15%, and treat i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com