Preparation method of zinc anode oxidation film layer

A technology of oxide film layer and zinc anode, which is applied in the direction of anodic oxidation, etc., can solve the problems that the comprehensive application performance of the film layer is not reported in detail, the hardness of the film layer is low, and the application performance is poor, so as to improve corrosion resistance, simple preparation process, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

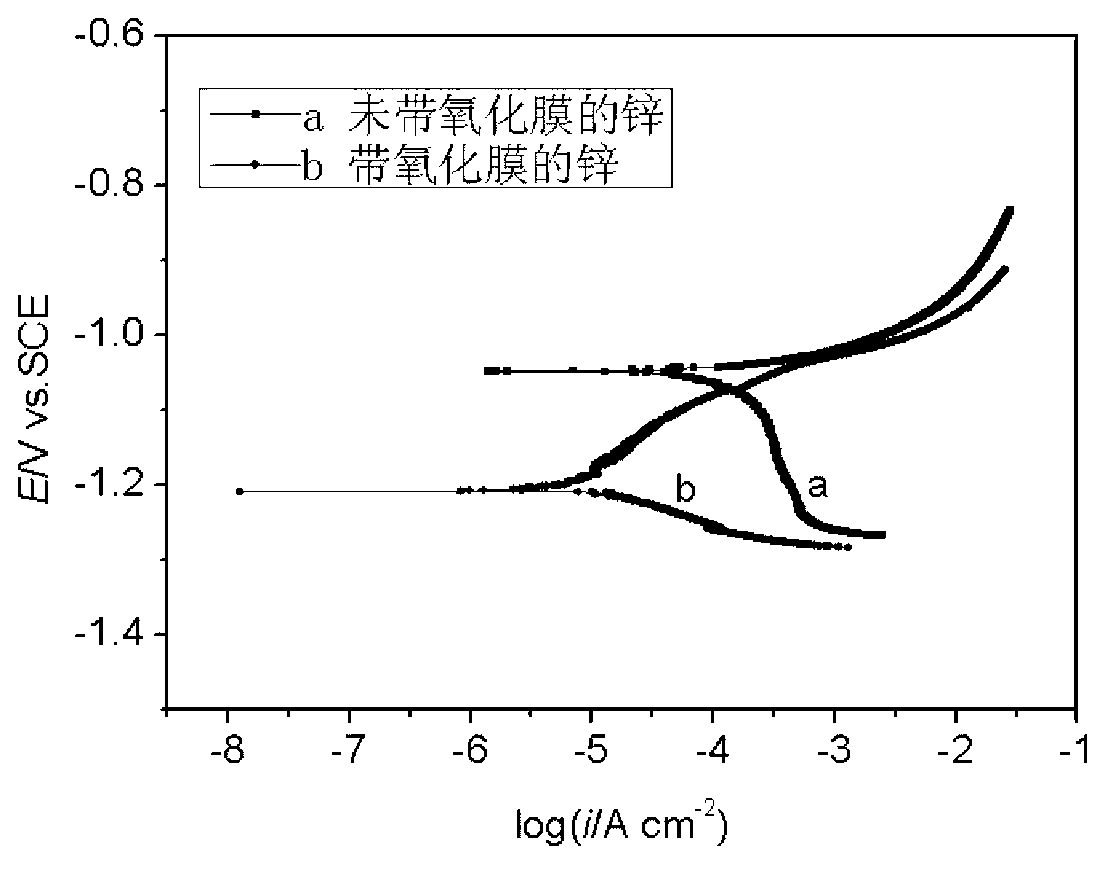

Image

Examples

Embodiment 1

[0014] The concrete processing steps of the present embodiment are:

[0015] (1) Substrate treatment: Grind the zinc sheet substrate (purity greater than 99.9%) with 1200-mesh SiC sandpaper, ultrasonically clean the surface with acetone, ethanol and deionized water for 5 minutes, and then seal it with sealant to form a working area of side length 5mm square substrate zinc surface;

[0016] (2) Electrolyte preparation: Add cerium chloride, hydrochloric acid, boric acid and citric acid into distilled water and stir well until the solid matter is completely dissolved, then add ethyl orthosilicate, and use conventional magnetic stirring at 40°C Stir at a stirring speed of 200r / min for 5min to make it fully hydrolyzed to obtain a prepared electrolyte, wherein the concentration of cerium chloride is 0.01mol / L, the concentration of ethyl orthosilicate is 0.001mol / L, and the concentration of hydrochloric acid The concentration is 0.5g / L, the concentration of boric acid is 2g / L, and...

Embodiment 2

[0020] The concrete processing steps of the present embodiment are:

[0021] (1) Substrate treatment: ultrasonically clean the surface of the zinc-coated carbon steel substrate with acetone, ethanol, and deionized water for 5 minutes in sequence, and seal it with sealant after drying to form a square substrate zinc surface with a working area of 5mm side length;

[0022] (2) Electrolyte preparation: Add cerium chloride, hydrochloric acid, boric acid and citric acid into distilled water and stir well until all solid substances are dissolved, then add ethyl orthosilicate, and use a conventional magnetic stirrer at a temperature of 50°C Stir at a stirring speed of 200r / min for 5 minutes to fully hydrolyze it to obtain a prepared electrolyte, wherein the concentration of cerium chloride is 0.05mol / L, the concentration of ethyl orthosilicate is 0.003mol / L, and the concentration of hydrochloric acid 2g / L, the concentration of boric acid is 4g / L, and the concentration of citric aci...

Embodiment 3

[0025] The concrete processing steps of the present embodiment are:

[0026] (1) Substrate treatment: Grind the zinc sheet substrate with 1200-mesh SiC sandpaper, ultrasonically clean the surface with acetone, ethanol, and deionized water for 5 minutes in turn, and then seal it with sealant to form a square with a working area of 5mm side length;

[0027] (2) Preparation of electrolyte: Add cerium chloride, hydrochloric acid, boric acid and citric acid into distilled water and stir well until all solid substances are dissolved, then add ethyl orthosilicate, and use conventional magnetic force at 45°C The stirrer was stirred at a stirring speed of 200r / min for 5min to make it fully hydrolyzed, and the prepared electrolyte was obtained, wherein the concentration of cerium chloride was 0.03mol / L, the concentration of ethyl orthosilicate was 0.002mol / L, hydrochloric acid The concentration of boric acid is 1g / L, the concentration of boric acid is 3g / L, and the concentration of ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com