Preparation method of resin-wrapped aluminum hydroxide

A technology of aluminum hydroxide and resin coating, applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve the problem of mechanical properties and processing properties of polymer materials, small change in particle size of aluminum hydroxide particles, compatibility The problem of poor flame retardant effect will not be reduced, the dispersion and compatibility will be good, and the compatibility will be good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 55g of median diameter D to a 1000mL beaker 50 3.89 μm raw material aluminum hydroxide particles, 10.0 g ammonium persulfate and 500 mL deionized water, control the pH to 6.5, stir at 20°C for 24 hours, suction filter and dry to obtain aluminum hydroxide particles anchored by initiator ammonium persulfate ; Add 10.0g ammonium persulfate-anchored aluminum hydroxide particles, 0.2g polyvinylpyrrolidone, 0.8g sodium lauryl sulfate and 150mL deionized water into a 250mL three-necked flask, stir vigorously to disperse, heat to 80°C, slowly drop Add 8.0 g of styrene monomer, and drop it in about 1 hour; then continue to react for 8 hours, cool, wash, filter, and extract with tetrahydrofuran for 24 hours to obtain polystyrene resin-coated aluminum hydroxide.

Embodiment 2

[0029] Add 55g of median diameter D to a 1000mL beaker 50 Aluminum hydroxide particles of 5.12 μm in size, 20.0 g of ammonium persulfate and 500 mL of deionized water, controlled to pH 6.5, stirred at 25°C for 24 hours, suction filtered and dried to obtain aluminum hydroxide particles anchored by initiator ammonium persulfate ; Add 10.0g of ammonium persulfate-anchored aluminum hydroxide particles, 0.3g of polyvinylpyrrolidone, 1.0g of sodium lauryl sulfate and 150mL of deionized water into a 250mL three-neck flask, stir vigorously to disperse, heat to 80°C, and slowly drop Add 10.0g of methyl methacrylate monomer, and drop it in about 1 hour; then continue to react for 8 hours, cool, wash, filter, and extract with tetrahydrofuran for 24 hours to obtain polymethyl methacrylate resin-coated hydrogen alumina.

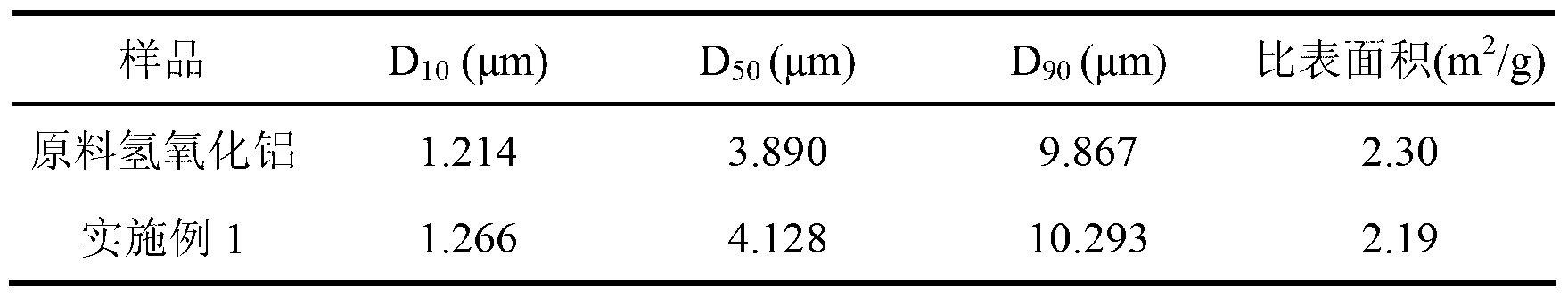

[0030] The characterization of the product that embodiment 1 and embodiment 2 make:

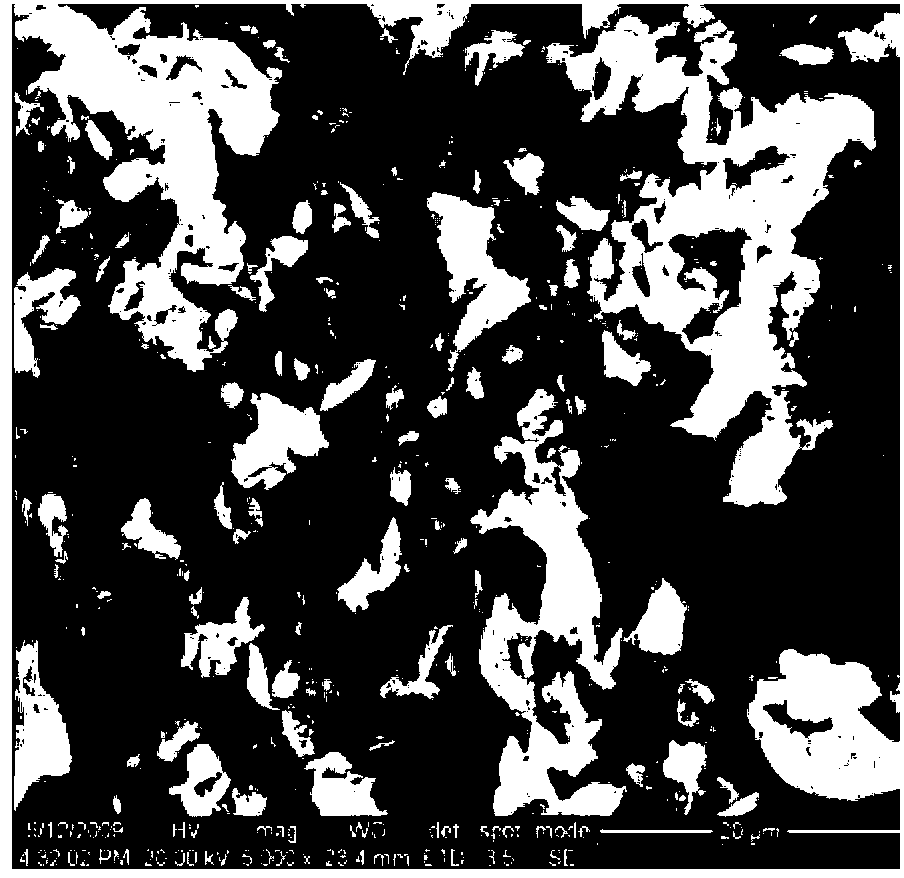

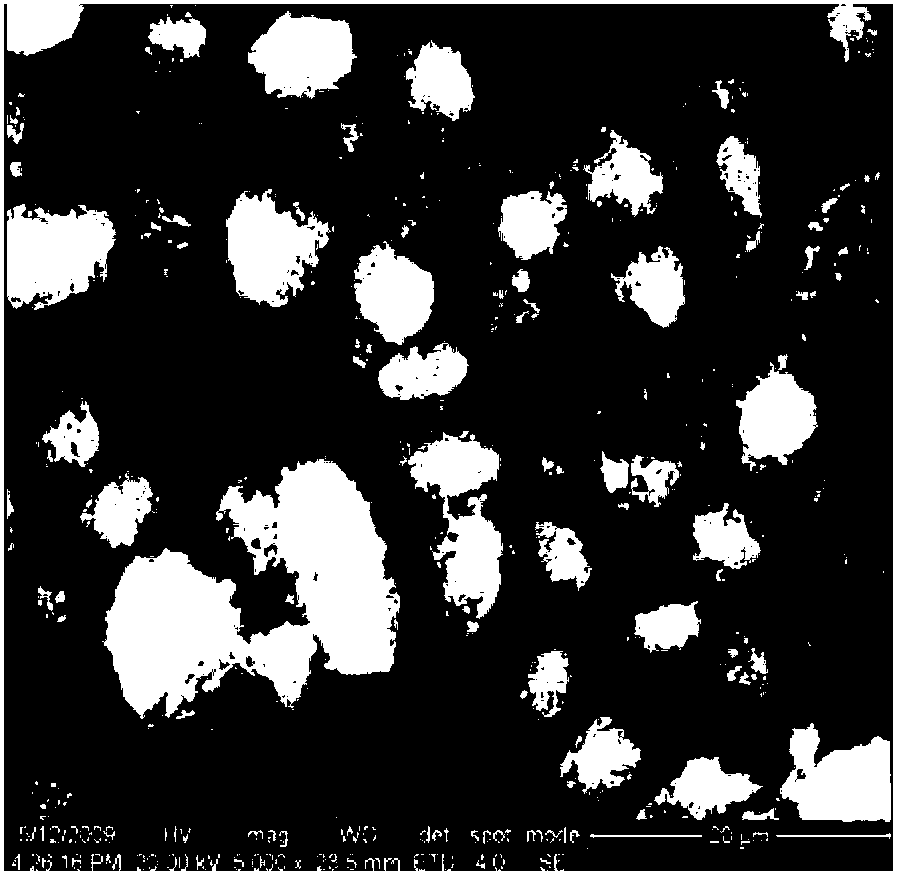

[0031] Observation of surface morphology: The morphology of raw aluminum hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com