Modified inorganic lithium silicate binder, and preparation method and use thereof

A lithium silicate and binder technology, which is applied in the direction of inorganic binders, adhesives, polymer binder additives, etc., can solve the problems of poor water resistance of coatings, difficult applicability, and fragile polymers, etc., to achieve Fast film forming speed, simple equipment, and less air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

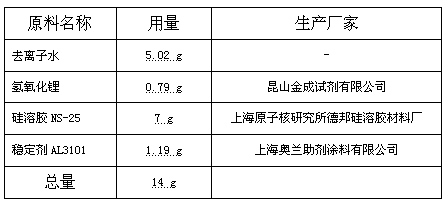

[0046] a. Lithium silicate

[0047]

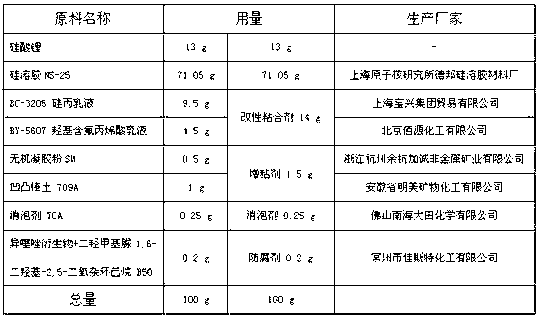

[0048] b. Modified inorganic lithium silicate binder

[0049]

[0050] Preparation:

[0051] The first step: the preparation of lithium silicate:

[0052] Put the deionized water in the stirred tank, add lithium hydroxide and stabilizer under the stirring condition of 80-90rpm, stir for 10-15min, then quickly add the silica sol under the high-speed stirring of 900-1400rpm, and the reaction temperature is 40-45 ℃, after high-speed dispersion for 5 hours, stop stirring and react in a static state for 96-120 hours, it is transparent and ready for use;

[0053] The second step: the preparation of lithium silicate binder:

[0054] Add the silica sol in the binder into the stirring tank, add lithium silicate, modified adhesive, tackifier, defoamer and preservative under the stirring condition of 80-90rpm, and stir at room temperature for 30-60min , the sampling test pH value is 11, and filtering to obtain a modified inorganic lithium s...

Embodiment 2

[0056] a. Lithium silicate

[0057]

[0058]b. Modified inorganic lithium silicate binder

[0059]

[0060] Preparation:

[0061] The first step: the preparation of lithium silicate:

[0062] Put the deionized water in the stirred tank, add lithium hydroxide and stabilizer under the stirring condition of 80-90rpm, stir for 10-15min, then quickly add the silica sol under the high-speed stirring of 900-1400rpm, and the reaction temperature is 40-45 ℃, after high-speed dispersion for 5 hours, stop stirring and react in a static state for 96-120 hours, then use;

[0063] The second step: the preparation of lithium silicate binder:

[0064] Add the silica sol in the binder into the stirring tank, add lithium silicate, modified adhesive, tackifier, defoamer and preservative under the stirring condition of 80-90rpm, and stir at room temperature for 30-60min , the sampling test pH value is 11, and filtering to obtain a modified inorganic lithium silicate binder.

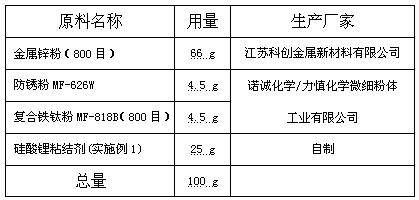

Embodiment 3

[0066] a. Lithium silicate

[0067]

[0068] b. Modified inorganic lithium silicate binder

[0069]

[0070] Preparation:

[0071] The first step: the preparation of lithium silicate:

[0072] Put the deionized water in the stirred tank, add lithium hydroxide and stabilizer under the stirring condition of 80-90rpm, stir for 10-15min, then quickly add the silica sol under the high-speed stirring of 900-1400rpm, and the reaction temperature is 40-45 ℃, after high-speed dispersion for 5 hours, stop stirring and react in a static state for 96-120 hours, then use;

[0073] The second step: the preparation of lithium silicate binder:

[0074] Add the silica sol in the binder into the stirring tank, add lithium silicate, modified adhesive, tackifier, defoamer and preservative under the stirring condition of 80-90rpm, and stir at room temperature for 30-60min , the sampling test pH value is 11, and filtering to obtain a modified inorganic lithium silicate binder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com