Metal-doped polyaniline and polypyrrole compound carbonization electric catalyst and preparation method thereof

An electrocatalyst, polyaniline technology, applied in physical/chemical process catalysts, chemical instruments and methods, circuits, etc., can solve the problems of battery cost hindering the commercialization of fuel cells, high price, affecting battery output performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 360 μL of pyrrole monomer in 30 mL of secondary water to form a solution of pyrrole monomer as solution A; dissolve 1.14 g of ammonium persulfate in 10 mL of secondary water to form a solution as solution B. The above-mentioned solution A and solution B were quickly mixed, and after fully stirring, they were reacted at 6°C for 24 hours. After the reaction was completed, 360 μL of aniline monomer and 1.14 g of ammonium persulfate solid were added, and reacted at 20°C for 24 hours to form paste. The above paste was spin-dried with a rotary evaporator, and then vacuum-dried for 24 hours to obtain a catalyst precursor. Put the dried catalyst precursor into a tube furnace, and pass through N for half an hour 2 Fill the tube furnace with N 2 , then the temperature was raised from room temperature to 350°C for 2 hours, and then continued to rise to 700°C for 2 hours at a rate of 2°C / min, then stopped heating, cooled naturally to room temperature and stopped N 2 ,...

Embodiment 2

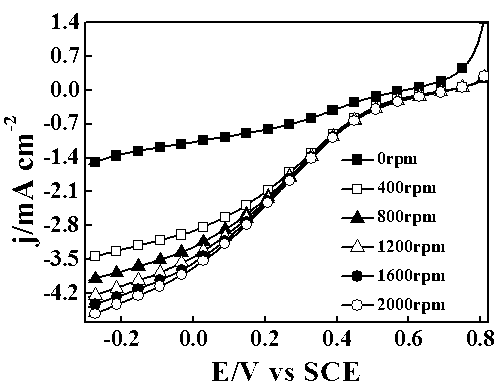

[0031] The preparation process of the electrocatalyst for the direct carbonization of the polyaniline and polypyrrole composite is the same as in Example 1. The test was carried out in 1 mol / L NaOH aqueous solution saturated with oxygen. The scanning speed is 5 mV / s, and the corresponding linear scanning curve is shown in figure 1 . The onset potential of the oxygen reduction reaction is -0.113 V (vs SCE), and the current density is 2.69mA cm -2 -0.5V (vs SCE) 2000rpm.

Embodiment 3

[0033] Dissolve 360 μL of pyrrole monomer in 30 mL of secondary water to form a solution of pyrrole monomer as A; 1.3 g of FeCl 3 6H 2 O solid was dissolved in 10mL of secondary water, and then 1.14g of ammonium persulfate was added, stirred evenly, and the formed solution was recorded as B. Mix the above-mentioned solutions A and B quickly, stir them well, and react at 6°C for 24 hours. After the reaction is completed, add 360 μL of aniline monomer and 1.14 g of ammonium persulfate solid, and react at 20°C for 24 hours to form a paste. shape. The above paste was spin-dried with a rotary evaporator, and then vacuum-dried for 24 hours to obtain a catalyst precursor. Put the dried catalyst precursor into a tube furnace, and pass through N for half an hour 2 Fill the tube furnace with N 2 , then the temperature was raised from room temperature to 350°C for 2 hours, and then continued to rise to 700°C for 2 hours at a rate of 2°C / min, then stopped heating, cooled naturally t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com