Condensed double-component organosilicon sealant and preparation method thereof

A silicone and sealant technology, applied in the field of sealants, can solve the problems of rapid curing, unsatisfactory thixotropic mechanical properties, etc., and achieve excellent aging resistance, good mechanical properties, and adjustable operating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

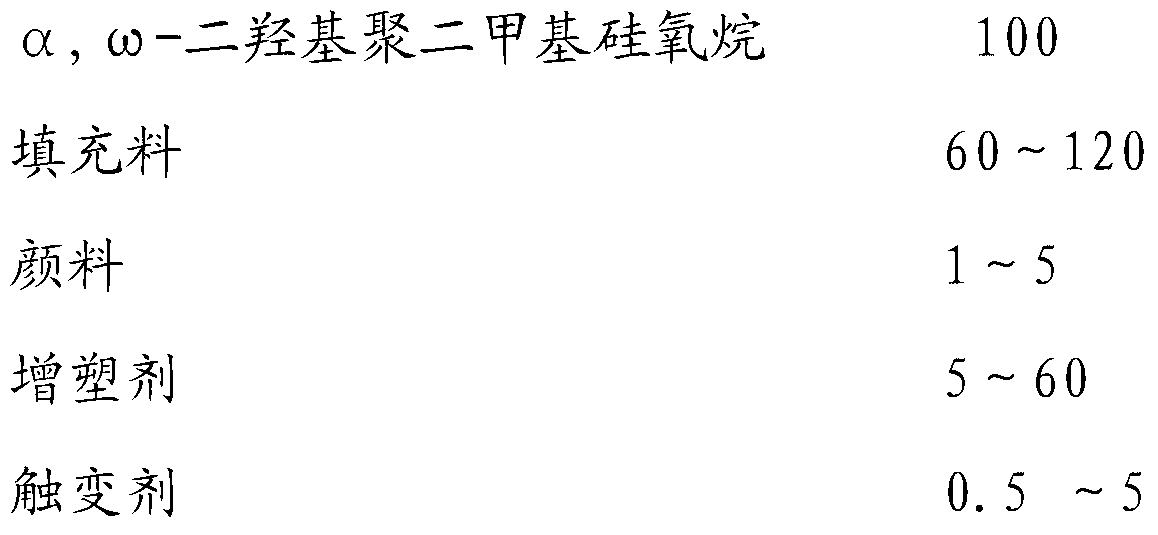

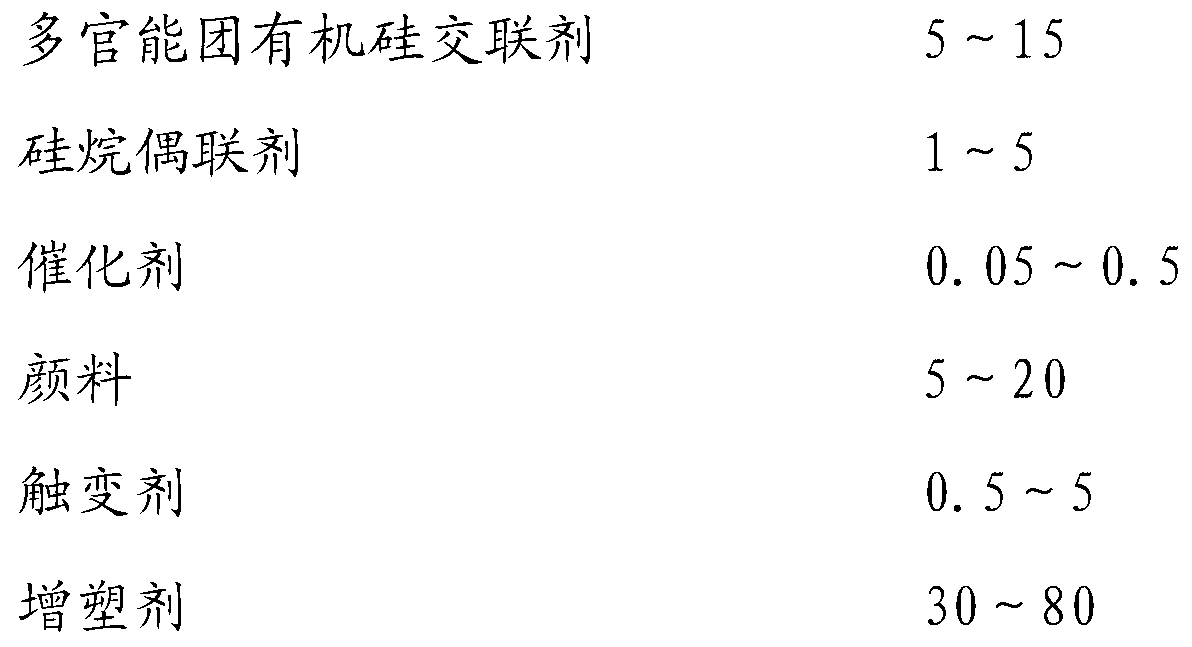

Method used

Image

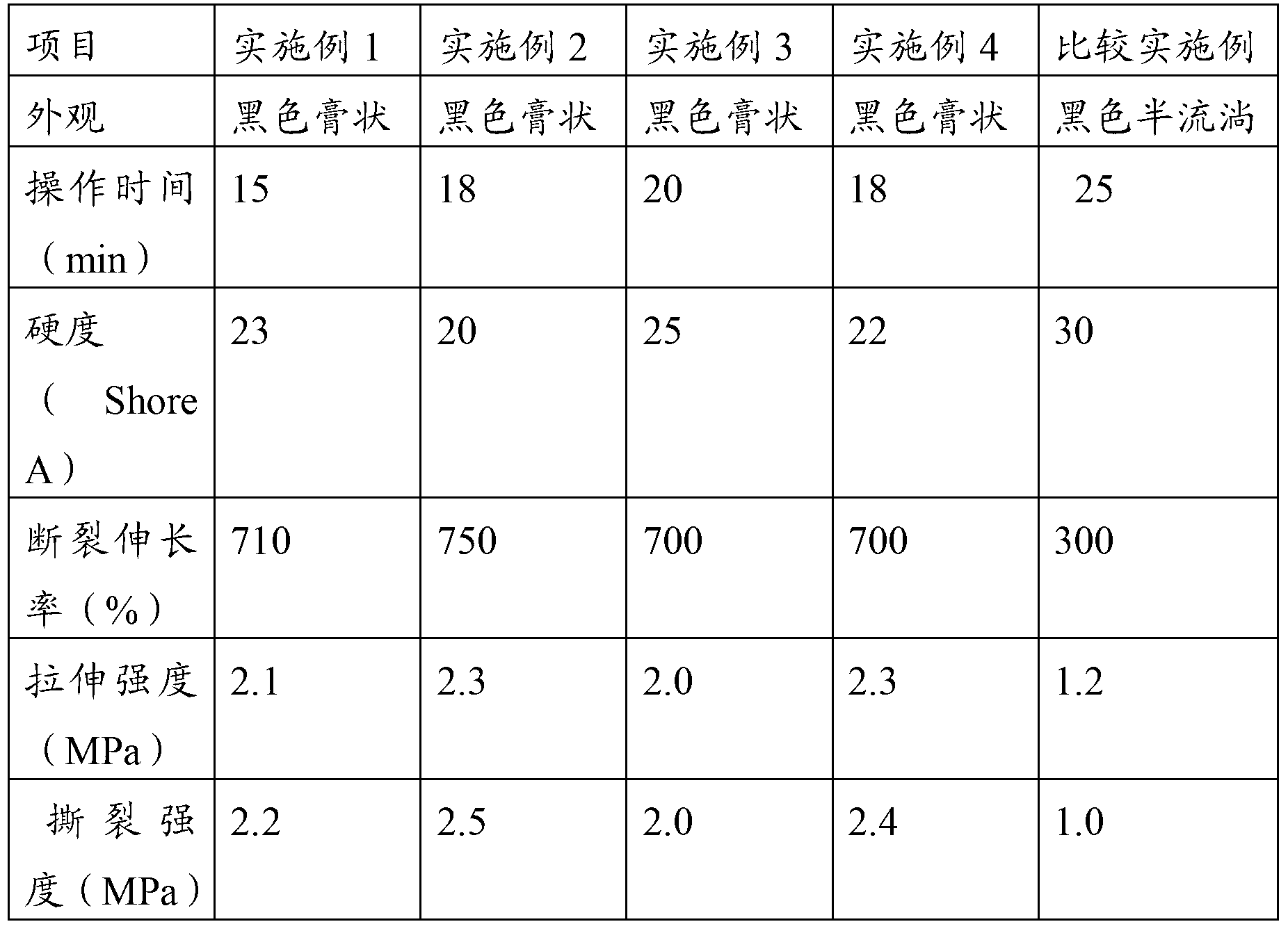

Examples

Embodiment 1

[0034] In parts by weight, add 100 parts of 107 glue with a viscosity of 3000cps, 85 parts of a mixture of light calcium carbonate and heavy calcium carbonate, 2 parts of titanium dioxide, 5 parts of simethicone with a viscosity of 100cps, and 3 parts of fumed silica Mixer, stirring under 0.099mpa vacuum for 2 hours to obtain A component.

[0035] In parts by weight, add 80 parts of simethicone oil with a viscosity of 300cps, 20 parts of U carbon black, and 5 parts of fumed silica into the reactor for mixing, slowly raise the temperature to 120°C, then keep the temperature constant, and stir under a vacuum of 0.099mpa After 1 hour, lower the temperature to 30°C, add 5 parts of ethyl orthosilicate, 1 part of γ-aminopropyltriethoxysilane, and 0.05 part of dibutyltin dilaurate under nitrogen atmosphere, and obtain component B after mixing. .

[0036] Mix the prepared component A and component B uniformly at a weight ratio of 2:1, vacuum defoam, and cure to obtain a condensation-...

Embodiment 2

[0038] In terms of parts by weight, add 100 parts of compound 107 glue with a viscosity of 20000cps and a viscosity of 10000cps, 60 parts of light calcium carbonate, 5 parts of titanium dioxide, 30 parts of dimethyl silicone oil with a viscosity of 500cps, and 5 parts of fumed silica into the mixer , and stirred for 3 hours under a vacuum of 0.099mpa to obtain component A.

[0039] In parts by weight, add 60 parts of simethicone oil with a viscosity of 1000cps, 8 parts of U carbon black, and 5 parts of fumed silica into the reaction kettle for mixing, slowly raise the temperature to 120°C, keep the temperature, and stir under a vacuum of 0.099mpa After 1.5 hours, cool down to 30°C, add 10 parts of a mixture of ethyl orthosilicate and methyl orthosilicate, and 3 parts of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane under nitrogen atmosphere, 0.1 part of dibutyltin diacetate and dibutyltin dilaurate mixture, after mixing to obtain component B.

[0040] Mix the prepared compon...

Embodiment 3

[0042] In parts by weight, add 100 parts of 107 glue with a viscosity of 2500cps, 120 parts of a mixture of silicon micropowder and light calcium carbonate, 1 part of titanium dioxide, 60 parts of simethicone oil with a viscosity of 500cps, and 0.5 parts of organic bentonite into the mixer, at 0.099 Stirring under mpa vacuum for 4 hours to obtain component A.

[0043] In parts by weight, add 30 parts of simethicone oil with a viscosity of 500 cps, 12 parts of a mixture of titanium dioxide and U carbon black, and 0.5 parts of organic bentonite into the reactor and mix them. After stirring for 2 hours, the temperature was lowered to 30°C, and 15 parts of a mixture of dimethyldiethoxysilane and ethyl orthosilicate, γ-aminopropyltriethoxysilane and N-(β-ammonia 5 parts of ethyl)-γ-aminopropyltrimethoxysilane mixture, 0.3 part of dibutyltin dilaurate, mixed well to obtain component B.

[0044] Mix the prepared component A and component B uniformly at a weight ratio of 5:1, vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com