Non-vacuum preparation method of a CZTS or CZTSe thin film not containing carbon layer

A non-vacuum, thin-film technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of toxicity, environmental hazards, etc., and achieve the effect of simple preparation process, excellent performance, and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

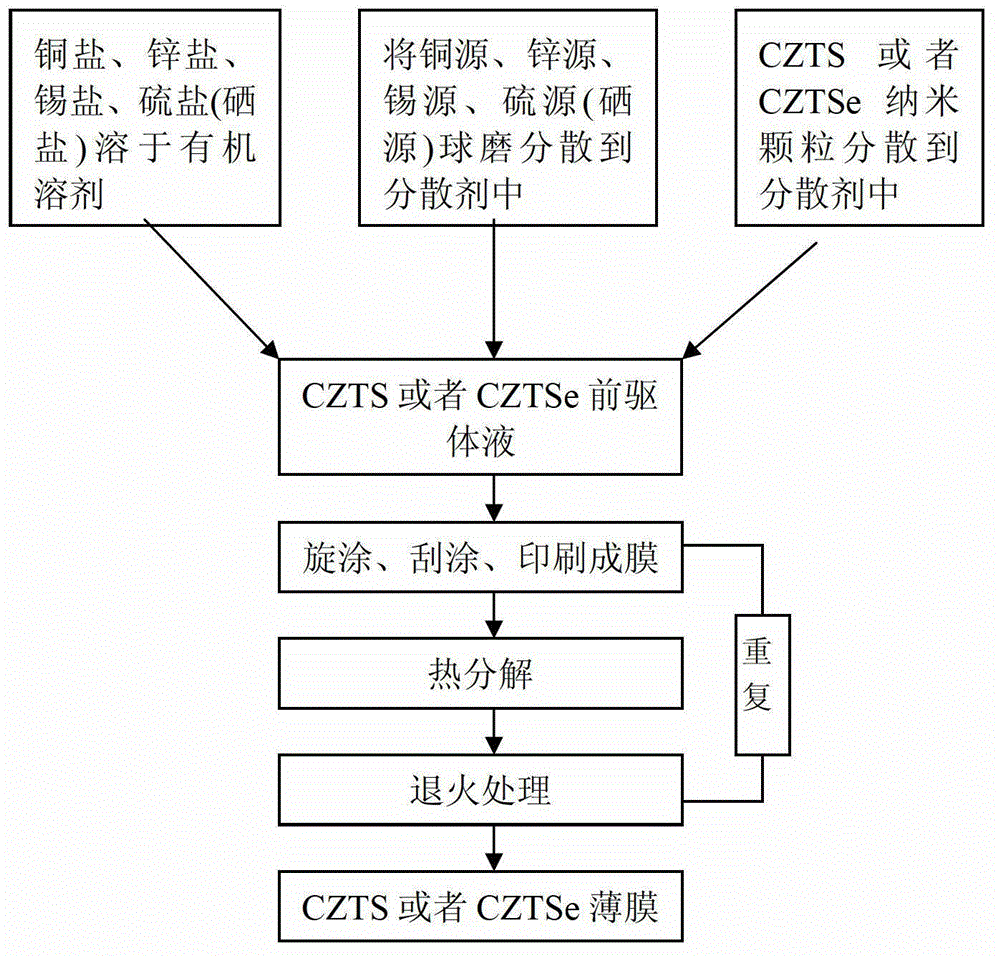

Method used

Image

Examples

Embodiment 1

[0038] In this experiment, the CZTS precursor fluid was prepared by the sol-gel method, and then spin-coated into a film. The specific steps are as follows:

[0039] 1. Preparation of CZTS precursor fluid: Dissolve 0.8500g copper nitrate trihydrate, 0.5360g zinc acetate dihydrate, 0.4513g stannous chloride dihydrate and 0.8380g thiourea in 2.5mL dimethyl sulfoxide, and then at room temperature Stir to obtain a light yellow, clear and transparent solution.

[0040] 2. Spin-coating the above-mentioned precursor liquid on the Mo-plated glass with a homogenizer at a rotation speed of 3000 rpm and a spin coating time of 40 s to obtain a CZTS wet film with a thickness of 200 nm.

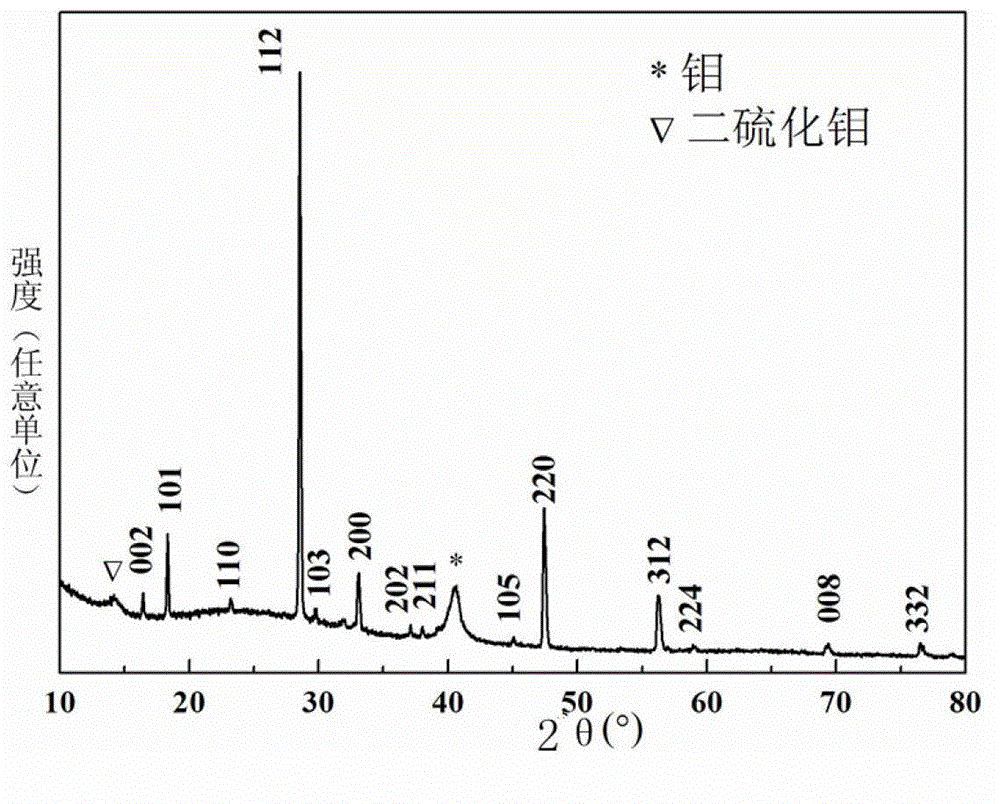

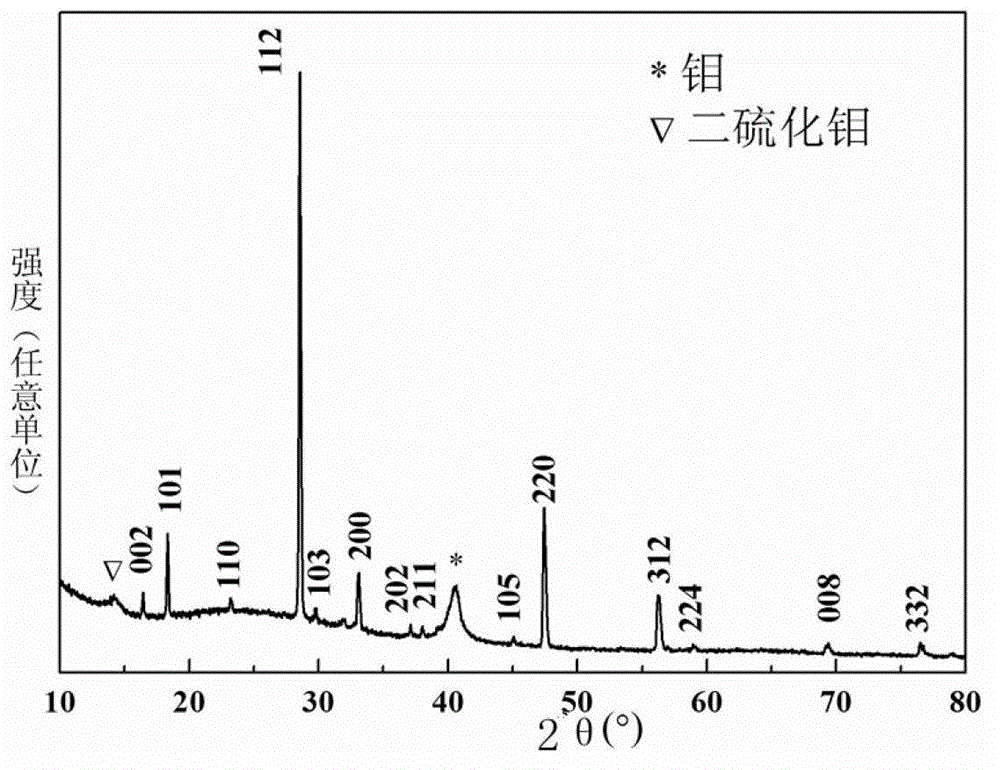

[0041] 3. Place the wet film in a tubular annealing furnace, thermally decompose it at 280°C for 5 minutes, and anneal it at 530°C for 5 minutes in an argon atmosphere. Repeat the above spin coating, thermal decomposition, and annealing process 9 times, and finally obtain the CZTS film.

Embodiment 2

[0043] In this experiment, the CZTS precursor fluid was prepared by the sol-gel method, and then spin-coated into a film. The specific steps are as follows:

[0044] 1. Preparation of CZTS precursor fluid: Dissolve 0.8600g copper nitrate trihydrate, 0.5360g zinc acetate dihydrate, 0.5360g stannous chloride dihydrate and 1.080g thiourea in 2.5mL dimethyl sulfoxide, and then at room temperature Stir to obtain a light yellow, clear and transparent solution.

[0045] 2. Spin-coating the above-mentioned precursor liquid on the Mo-plated glass with a homogenizer at a speed of 1500rpm and a spin-coating time of 40s to obtain a CZTS wet film with a thickness of 500nm.

[0046] 3. Place the wet film in a tubular annealing furnace, thermally decompose it at 250°C for 5 minutes, and anneal it at 550°C for 5 minutes in a nitrogen atmosphere. The above spin coating, thermal decomposition, and annealing process were repeated 14 times, and finally a CZTS film was obtained.

Embodiment 3

[0048] In this experiment, CZTS nanoparticles are prepared by hydrothermal method, then dispersed in an organic solvent with a binder, and spin-coated to form a film. The specific steps are as follows:

[0049] 1. Preparation of CZTS precursor fluid: Dissolve 0.8700g copper acetate monohydrate, 0.6300g zinc acetate dihydrate, 0.5000g stannous chloride dihydrate and 1.300g thiourea in a mixed solution of 20mL ethylenediamine and water (water and ethyl acetate). The volume ratio of diamine is 4). After stirring at room temperature for 10 hours, it is poured into an autoclave and reacted at 200°C for 24 hours, then cooled to room temperature, the black precipitate is centrifuged, and deionized water is used Washed with absolute ethanol several times to obtain black CZTS nanoparticles. Weigh 0.5 g of ethyl cellulose and dissolve it in 20 mL of ethanol, and then disperse CZTS nanoparticles into a mixture of ethanol and ethyl cellulose to obtain a CZTS precursor fluid.

[0050] 2. Spin-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com