Method and apparatus for sludge deep treatment and resource utilization

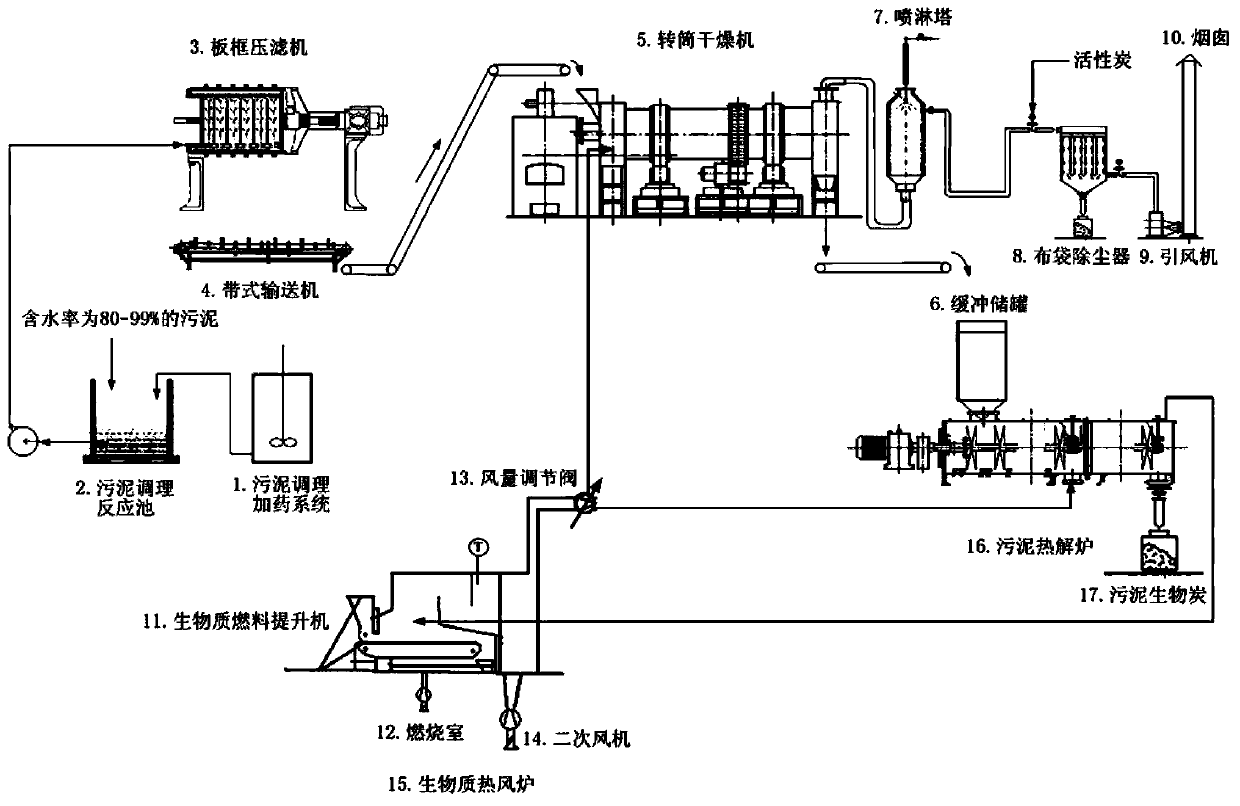

A technology for advanced treatment and sludge conditioning, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. It can solve the problems of low investment cost, difficult control, difficulty in ensuring treatment efficiency and Product quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] When the sludge is treated by the above device, first add 2000L of domestic sludge with a water content of 96% to the sludge conditioning reaction tank, then add 6kg of sodium hypochlorite and 30L of concentrated sulfuric acid, stir for 60min, and then add FeSO4 20kg, ZnCl 2 30kg and stirred for 3 minutes, and finally add 8kg of organic polymer coagulant octadecyltrimethylammonium chloride and stir for 3 minutes, then use a diaphragm plate frame filter press to feed the mud for 120 minutes under a pressure of 0.8MPa, and then use hydraulic pressure at 0.8MPa Press the diaphragm for 20 minutes under a certain pressure, weigh the mud cake, and determine that the moisture content of the sludge is 59%.

Embodiment 2

[0042] When the sludge is treated by the above device, first add 2000L of domestic sludge with a water content of 96% to the sludge conditioning reaction tank, then add 10kg of sodium hypochlorite and 40L of concentrated sulfuric acid, stir for 80min, and then add FeSO 4 20kg, ZnCl 2 30kg and stirred for 4 minutes, and finally added 8kg of organic polymer coagulant octadecyltrimethylammonium chloride and stirred for 4 minutes, then used a diaphragm plate and frame filter press to feed the mud for 120 minutes under a pressure of 0.8MPa, and then used hydraulic pressure at 0.8MPa Press the diaphragm for 20 minutes under a certain pressure, weigh the mud cake, and determine that the moisture content of the sludge is 56%. Example 3

Embodiment 3

[0043] When the sludge is treated by the above device, first add 2000L of domestic sludge with a water content of 96% to the sludge conditioning reaction tank, then add 6kg of sodium hypochlorite and 30L of concentrated sulfuric acid, stir for 60min, and then add FeSO 4 30kg, ZnCl 2 40kg was stirred for 4 minutes, and finally 8kg of organic polymer coagulant octadecyltrimethylammonium chloride was added and stirred for 4 minutes, and the diaphragm plate and frame filter press was used to feed the mud under the pressure of 0.8MPa for 120min, and then the hydraulic pressure was used to filter at 0.8MPa Press the diaphragm for 20 minutes under the pressure of 20 minutes, weigh the mud cake, and determine that the moisture content of the sludge is 58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com