Fluorescent carbon quantum dot, its light-emitting polymer based composite material and preparation method

A technology of light-emitting polymers and carbon quantum dots, which is applied in the direction of light-emitting materials, chemical instruments and methods, etc., can solve the problems of limited CDs application, low output, complicated preparation process and difficult realization, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

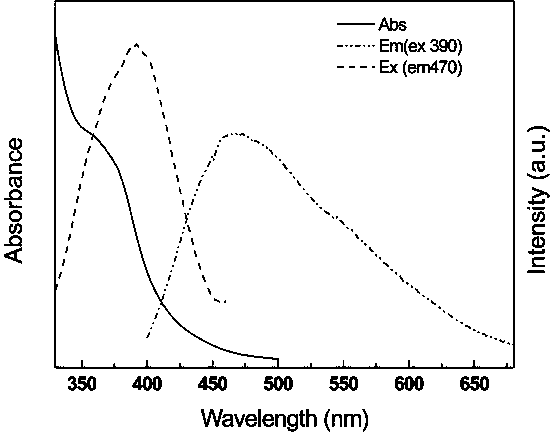

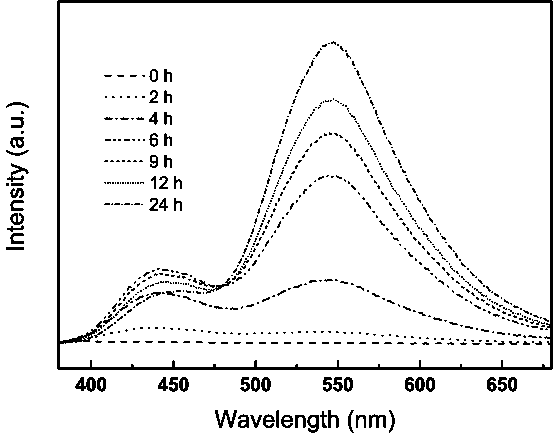

[0034] (1) 0.528g (3mmol) L-ascorbic acid dissolved in 60ml of ethanol and water mixed solution (volume ratio, ethanol: water = 1:1), add 7.92g (30mmol) N-(β-aminoethyl)-γ -Aminopropyltriethoxysilane (KH791), then reacted in an oil bath at 95°C under magnetic stirring for 24 hours, and cooled naturally to room temperature to obtain a mixed solution of fluorescent carbon quantum dots and silicone prepolymers, and the quantum of the purified product The efficiency is 13.5% (Table 1), and its fluorescence spectrum and UV-vis absorption are as follows figure 1 , transmission electron microscope pictures as figure 2 , its digital photos under visible light and 365nm ultraviolet light are as follows Figure 5 a, 5b, the digital photos of it dried on filter paper under visible light and 365nm ultraviolet light are as follows Figure 5 g, 5h.

[0035] (2) The product obtained in (1) was spin-evaporated at 50°C to remove the solvent, then spin-coated on a quartz plate, and cured in...

Embodiment 2

[0037] (1) 1.584g (9mmol) L-ascorbic acid dissolved in 60ml of ethanol and water mixed solution (volume ratio, ethanol: water = 1:0.8), add 2.124g (9mmol) γ-glycidyl ether oxypropyl trimethoxy Silane (KH560), then reacted in an oil bath at 80°C under magnetic stirring for 12 hours, and cooled naturally to room temperature to obtain a mixed solution of fluorescent carbon quantum dots and organosilicon prepolymer. The quantum efficiency of the purified product was 12.7% (Table 1) .

[0038] (2) The product obtained in (1) was spin-evaporated at 50°C to remove the solvent, then spin-coated on a quartz plate, and cured in an oven at 100°C for 5 hours to obtain a light-emitting polymer-based composite material.

Embodiment 3

[0040] (1) 5.28g (30mmol) L-ascorbic acid dissolved in 60ml of ethanol and water mixed solution (volume ratio, ethanol: water = 1:0.5), add 3.39g (15mmol) N-(β-aminoethyl)-γ -Aminopropyltrimethoxysilane (KH792), then reacted in an oil bath at 90°C under magnetic stirring for 5 hours, and cooled naturally to room temperature to obtain a mixed solution of fluorescent carbon quantum dots and silicone prepolymer, and the quantum efficiency of the purified product was 10.3% (Table 1).

[0041] (2) The product obtained in (1) was spin-evaporated at 50°C to remove the solvent, then spin-coated on a quartz plate, and cured in an oven at 80°C for 48 hours to obtain a light-emitting polymer-based composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com