Method for preparing spherical shell type catalyst for catalytic combustion of VOCs (volatile organic compounds)

A catalytic combustion and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Problems such as secondary pollution of products and high toxicity of organic waste gas are achieved to overcome the effects of easy poisoning, good adsorption and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

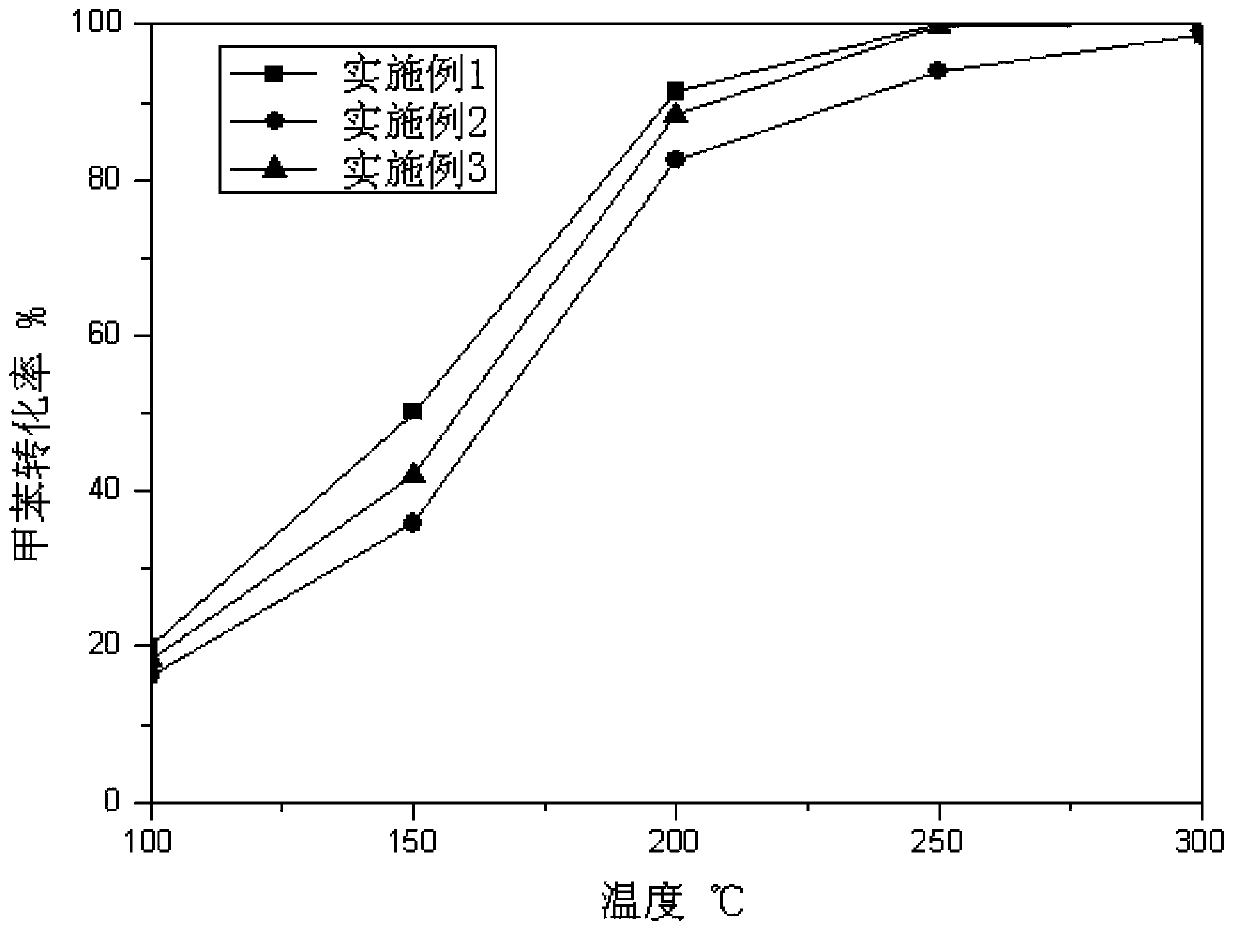

Embodiment 1

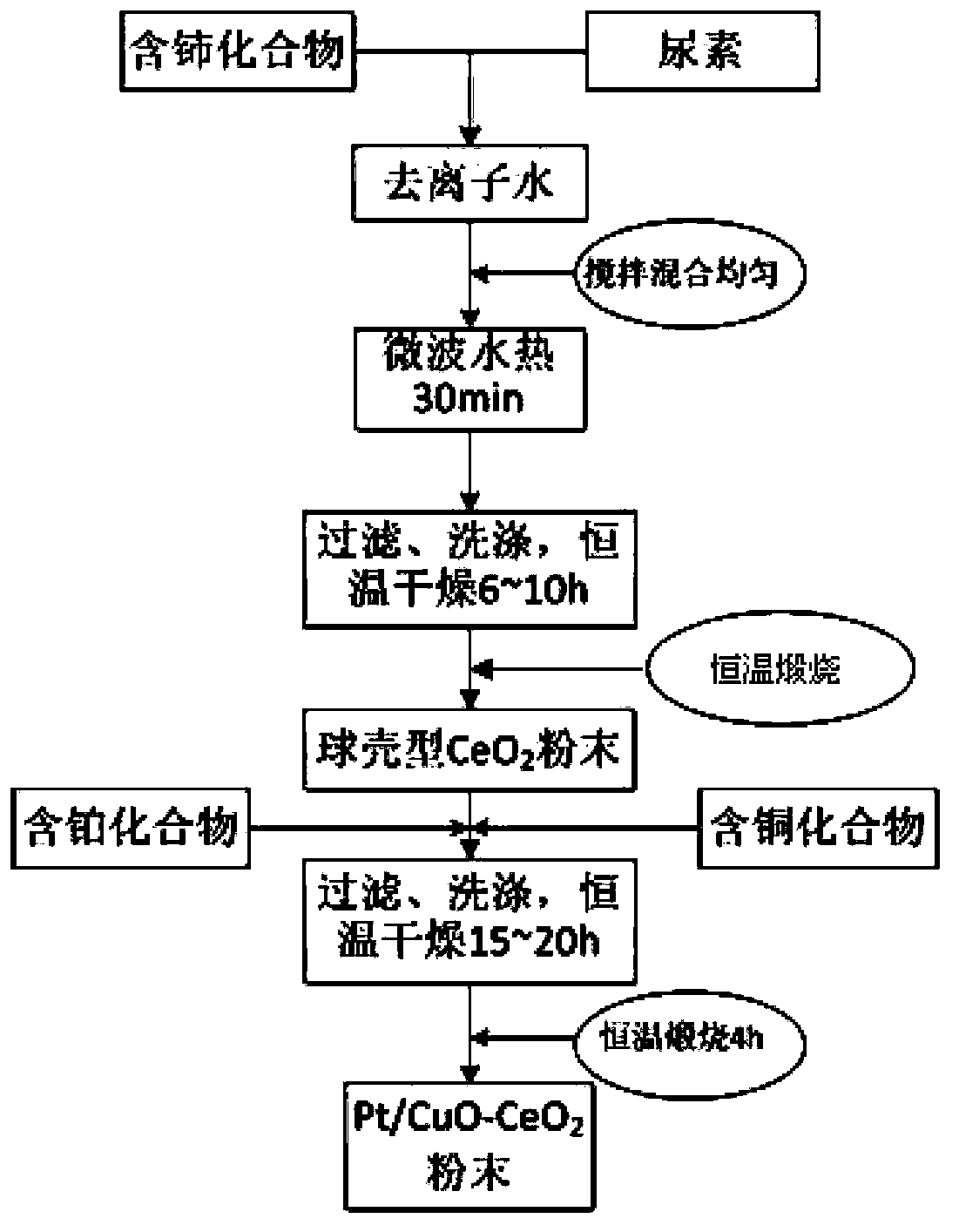

[0025] (1) Take 0.6mmol Ce (NO 3 ) 3 ·6H 2 O and 0.9mmol urea were dissolved in 60mL of deionized water, and after fully stirring, the mixture was poured into a polytetrafluoroethylene-lined hydrothermal kettle, and microwave hydrothermal heating was carried out in a microwave digestion instrument, with a programmed heating rate of 70°C / min. , the final temperature was 170°C and kept for 30 minutes.

[0026] (2) After cooling, the obtained precipitate was washed 3 times with absolute ethanol and then with deionized water 3 times, dried at 80°C for 6h, and calcined at 500°C for 2h to obtain spherical shell CeO 2 .

[0027] (3) Take 0.5g of the above-mentioned spherical shell CeO 2 powder, dissolved in 40mL deionized water, added 0.25mL H 2 PtCl 6 · 6H 2 O solution (10 mg Pt / mL) and 0.0502 g CuSO 4 mix,

[0028] (4) After stirring for 12 hours, filter, the obtained precipitate was washed with deionized water for 3 times, dried at 100°C for 20 hours, and then calcined at...

Embodiment 2

[0032] (1) Take 0.6mmol Ce (NO 3 ) 3 ·6H 2 O and 1.1mmol urea were dissolved in 60mL of deionized water. After fully stirring, the mixture was poured into a polytetrafluoroethylene-lined hydrothermal kettle. Microwave hydrothermal heating was carried out in a microwave digestion apparatus, and the programmed heating rate was set at 70°C / min. , and the final temperature was 160°C and kept for 30 minutes.

[0033] (2) After cooling, the obtained precipitate was washed with absolute ethanol for 3 times and then with deionized water for 3 times, dried at 60°C for 10 hours, and then calcined at 500°C for 2 hours to obtain spherical shell CeO 2 .

[0034] (3) Take 0.5g of the above-mentioned spherical shell CeO 2 powder, dissolved in 40mL deionized water, added 0.175mL [Pt(NH 3 ) 4 ](NO 3 ) 2 solution (10mg Pt / mL) and 0.1519g Cu(NO 3 ) 2 ·3H 2 O mix.

[0035] (4) After stirring for 15 hours, filter, the resulting precipitate was washed with deionized water for 3 times,...

Embodiment 3

[0039] (1) Take 0.6mmol Ce (NO 3 ) 3 ·6H 2 O and 1.2mmol urea were dissolved in 60mL of deionized water, and after fully stirring, the mixture was poured into a polytetrafluoroethylene-lined hydrothermal kettle, and microwave hydrothermal heating was carried out in a microwave digestion instrument, with a programmed heating rate of 70°C / min. , and the final temperature was 180°C and kept for 30 minutes.

[0040] (2) After cooling, the obtained precipitate was washed 3 times with absolute ethanol and then with deionized water 3 times, dried at 70°C for 8h, and calcined at 500°C for 2h to obtain spherical shell CeO 2 .

[0041] (3) Take 0.5g of the above-mentioned spherical shell CeO 2 powder, dissolved in 40mL deionized water, added 0.125mL H 2 PtCl 6 · 6H 2 O solution (10 mg Pt / mL) and 0.0803 g CuSO 4 mix.

[0042] (4) After stirring for 10 hours, filter, the obtained precipitate was washed with deionized water for 3 times, dried at 110°C for 18 hours, and then calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com