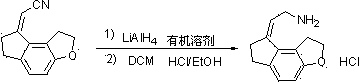

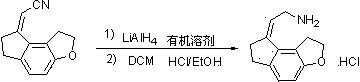

Preparation method of ramelteon intermediates

An equation and pressure control technology, applied in organic chemistry and other fields, can solve problems such as difficult to achieve 99%, increased difficulty in industrialization, large amount of Raney nickel, etc., to achieve the effect of simple operation, strong reduction activity, and reduced reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This example relates to a 2-(1,6,7,8-tetrahydro-2H-indeno-[5,4-b]furan-8-ylidene)ethylamine hydrochloride, and (S)- The preparation method of 2-(1,6,7,8-tetrahydro-2H-indeno-[5,4-b]furan-8-yl)ethylamine hydrochloride comprises the following specific steps:

[0038] Pour 4L of dichloromethane (DCM) or dichloroethane into a glass reactor, add 406g (1eq) diethyl cyanomethyl phosphate, cool down to -20°C and add sodium hydride in batches, the solution becomes viscous Then add 2L of dichloromethane, stir at -10°C for 30 minutes, then slowly add compound I solution dissolved in dichloromethane dropwise, wherein the mass of compound I is 400g (1eq), add the material and continue to stir the reaction. After the reaction was complete, add water to quench, extract and separate the liquids with ethyl acetate, wash the organic phase with a saturated aqueous sodium chloride solution, combine the organic phases, dry and spin dry to obtain 288g of compound II, with a mass yield of 72%...

Embodiment 2

[0048] This example relates to a 2-(1,6,7,8-tetrahydro-2H-indeno-[5,4-b]furan-8-ylidene)ethylamine hydrochloride, and (S)- The preparation method of 2-(1,6,7,8-tetrahydro-2H-indeno-[5,4-b]furan-8-yl)ethylamine hydrochloride comprises the following specific steps:

[0049] Pour 4L of anhydrous tetrahydrofuran into a glass reactor, add 488g (1.2eq) of diethyl cyanomethyl phosphate, cool down to -10°C and add sodium methoxide in batches, when the solution becomes viscous, add 2L of tetrahydrofuran, - Stir at 8°C for 30 minutes, then slowly add compound I solution dissolved in tetrahydrofuran dropwise, wherein the mass of compound I is 400g (1eq), add materials and continue to stir the reaction, after the reaction of the central control raw material is complete, add water to quench, and use ethyl acetate Extraction and liquid separation, the organic phase was washed with a saturated aqueous sodium chloride solution, the organic phases were combined, dried and spin-dried to obtain ...

Embodiment 3

[0053] This example relates to a 2-(1,6,7,8-tetrahydro-2H-indeno-[5,4-b]furan-8-ylidene)ethylamine hydrochloride, and (S)- The preparation method of 2-(1,6,7,8-tetrahydro-2H-indeno-[5,4-b]furan-8-yl)ethylamine hydrochloride comprises the following specific steps:

[0054] Pour 4L of dichloromethane into a glass reactor, add 610g (1.5eq) of diethyl cyanomethyl phosphate, cool down to 10°C, add sodium tert-butoxide in batches, and add 2L of dichloromethane when the solution becomes viscous Methane, stirred at -5°C for 30 minutes, and then slowly added dropwise the compound I solution dissolved in dichloromethane, wherein the mass of compound I was 400g (1eq), adding materials and continuing to stir the reaction, and quenched with water after the reaction of the central control raw material was complete , extracted with ethyl acetate for liquid separation, the organic phase was washed with saturated aqueous sodium chloride solution, the organic phases were combined, dried and spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com