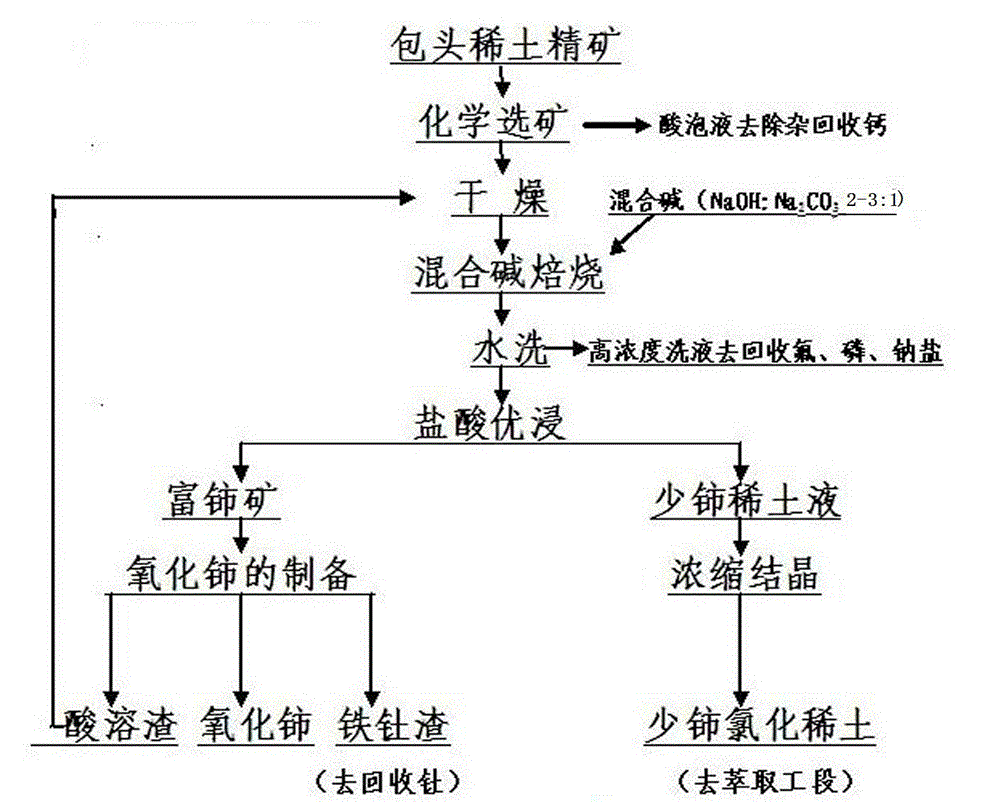

Method for decomposing and extracting Baotou rare earth ore through mixed alkali roasting process

A Baotou rare earth and mixed alkali technology, applied in the direction of improving process efficiency, etc., to achieve good dissolution, reduce equipment investment, and good filtration and dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The adopted Baotou rare earth ore is 4 tons, and the main components are: REO 41.50%; F 6.11%; P 4.05%; Fe 15.44%; CaO 7.98%.

[0040] (1) Chemical beneficiation and concentrate drying

[0041] Baotou rare earth ore is chemically processed, filtered and dehydrated, and dried to obtain low calcium rare earth ore. The filtrate is concentrated to produce calcium chloride after removing impurities.

[0042] Process conditions: solid-liquid ratio 1:4, ore: hydrochloric acid 1:1.0. Mine 4 tons, add water 12M 3 , 4 tons of hydrochloric acid were added until the pH was stable at 0.1, the reaction temperature was 25 ° C, and the time was 2 hours. Drying temperature: 500 ° C, 1.0 hours, 3 tons of dry ore, about 600 kg of calcium chloride.

[0043] (2) Mixed alkali roasting:

[0044] The mixed alkali is made of solid sodium hydroxide and powdered sodium carbonate in a weight ratio of: sodium hydroxide:sodium carbonate=2:1, which is pulverized and mixed. Mixing and roasting th...

Embodiment 2

[0057] The adopted Baotou rare earth ore is 4 tons, the main components are: REO 50.18%; F 7.65%; P 4.58%;

[0058] Fe 6.10%; CaO 10.68%.

[0059] (1) Chemical beneficiation and ore drying

[0060] Baotou rare earth ore undergoes chemical beneficiation, dehydration by pressure filtration, drying to obtain low calcium rare earth ore, and the filtrate is concentrated to produce calcium chloride after removing impurities.

[0061] Process conditions:

[0062] The solid-liquid ratio is 1:5, the ore: hydrochloric acid (weight ratio) is 1:0.8, the ore is 4 tons, and the water is 17 M 3 , the pH was stabilized at 0.1 after the addition of 3.2 tons of hydrochloric acid, the reaction temperature was 60 ° C, and the time was 2 hours. Drying temperature: 520 ℃, time 1.25 hours. The dry ore of low calcium rare earth ore is about 3 tons, and the filtrate is concentrated to produce about 800kg of calcium chloride after removing impurities.

[0063] (2) Mixed alkali roasting:

[00...

Embodiment 3

[0082] 4 tons of Baotou rare earth ore is used, and the main components are: REO 60.12%; F 6.85%; P 4.31%; Fe 6.52%; CaO4.86%.

[0083] (1) Chemical beneficiation and ore drying

[0084] Baotou rare earth ore undergoes chemical beneficiation, dehydration by pressure filtration, drying to obtain low calcium rare earth ore, and the filtrate is concentrated to produce calcium chloride after removing impurities.

[0085] Process conditions: solid-liquid ratio 1:4; hydrochloric acid weight ratio 1:0.5; ore 4 tons, add water 14M 3 , 2 tons of hydrochloric acid were added until the pH was stabilized at 0.1, the reaction temperature was 85 ° C, and the time was 2 hours. Drying temperature: 550℃, drying time 1.5 hours, about 3 tons of dry ore, about 360kg of calcium chloride.

[0086] (2) Mixed alkali roasting:

[0087] The mixed alkali is composed of sodium hydroxide and sodium carbonate in a weight ratio: sodium hydroxide:sodium carbonate=3:1.

[0088] The low-calcium rare earth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com