Lithium ion capacitor positive plate and lithium ion capacitor using same

A technology of lithium ions and capacitors, which is applied in the field of electrochemical energy storage devices, can solve problems such as complicated process and lower energy density of lithium ion capacitors, and achieve the effects of good conductivity, improved energy density and power density, and high adsorption charge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

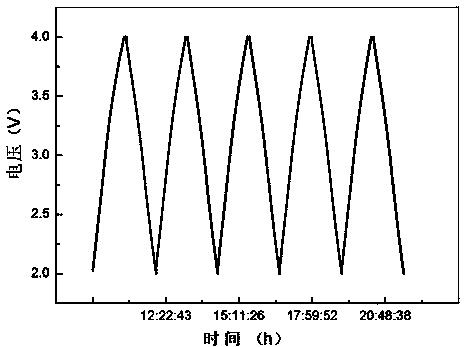

Embodiment 1

[0025] Production of positive electrode sheet: Weigh functional graphene (GNS), polyvinylidene fluoride (PVDF) binder N-base- 2-ylpyrrolidone solution, conductive agent Super P, mix the three into a uniform slurry according to the mass ratio GNS: PVDF: Super P=85:5:10, and apply the slurry evenly on the surface with a porosity of 30 % on the aluminum foil current collector, the surface density of the slurry on the pole piece is 5mg / cm 2 , the size of the pole piece is 3cm × 5cm, and the aluminum strip tab is welded.

[0026] Production of negative electrode sheet: Weigh modified natural graphite (G), styrene-butadiene rubber emulsion (SBR) / sodium carboxymethyl cellulose (CMC), conductive agent Super P, according to the mass ratio G : SBR : CMC : Super P = 92 : 3.5 : 1.5 : 3 Mix it into a uniform slurry, and apply the slurry evenly on the copper foil current collector with a porosity of 50%, and the surface density of the slurry on the pole piece is 5mg / cm 2 , the size of t...

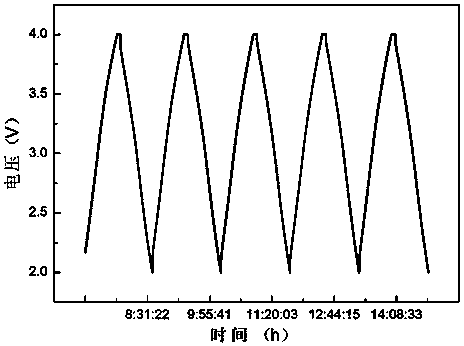

Embodiment 2

[0035] The production of the positive electrode sheet: the functional graphene in Example 1 is replaced with a specific surface area of 2300 m 2 / g of the porous graphene material, all the other manufacturing processes of the positive electrode sheet are the same as in Example 1.

[0036] Production of the negative electrode sheet: the modified natural graphite in Example 1 was replaced with graphitized mesophase carbon microspheres, and the rest of the production process of the negative electrode sheet was the same as in Example 1.

[0037] Electrolyte and diaphragm use the same system as in Example 1.

[0038] According to the order of auxiliary electrode / diaphragm / negative electrode / diaphragm / positive electrode / diaphragm / negative electrode, the capacitor unit is formed in a stacked manner, and the two negative electrode tabs are welded together, placed in an aluminum-plastic case, and packaged.

[0039] Negative electrode pre-intercalation lithium method: the auxiliary e...

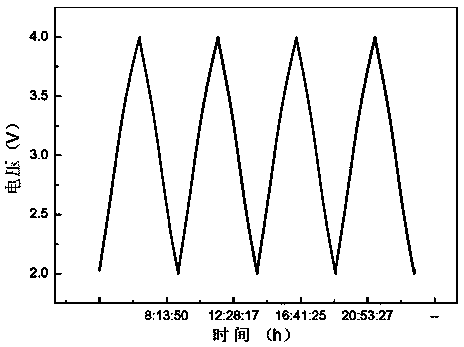

Embodiment 3

[0042] Production of the positive pole piece: the functional graphene in Example 1 was replaced with a graphene / titanium nitride (the content of titanium nitride was 15 wt%) composite material, and the rest of the production process of the positive pole piece was the same as in Example 1.

[0043] Production of the negative electrode sheet: the modified natural graphite in Example 1 was replaced with an artificial graphite material, and the rest of the production process of the negative electrode sheet was the same as in Example 1.

[0044] Electrolyte and diaphragm use the same system as in Example 1.

[0045] According to the order of auxiliary electrode / diaphragm / negative electrode / diaphragm / positive electrode / diaphragm / negative electrode, the capacitor unit is formed in a stacked manner, and the two negative electrode tabs are welded together, placed in an aluminum-plastic case, and packaged.

[0046] Negative electrode pre-intercalation lithium method: The auxiliary elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com