Lithium manganese phosphate positive electrode material and preparation method thereof

A positive electrode material, lithium manganese phosphate technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as lattice inversion defects of lithium manganese phosphate materials, and achieve good discharge capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] First, weigh 115g of ammonium dihydrogen phosphate, 181g of manganese citrate, 15g of glucose and 30g of sodium dodecylbenzene sulfonate, and disperse the above raw materials in 816g of deionized water; then add the above suspension In the autoclave for hydrothermal reaction, the reaction temperature is 200°C, and the reaction time is 10 hours; after the reaction, the filter cake is filtered and washed, and the filter cake is dried at 80°C for 8 hours to obtain the square manganese phosphate precursor Body; then the precursor powder and 36.94g of lithium carbonate are fully mixed, and then sintered at high temperature for 2 hours under the protection of nitrogen atmosphere, the sintering temperature is 500 ℃, and finally natural cooling to obtain square lithium manganese phosphate cathode material.

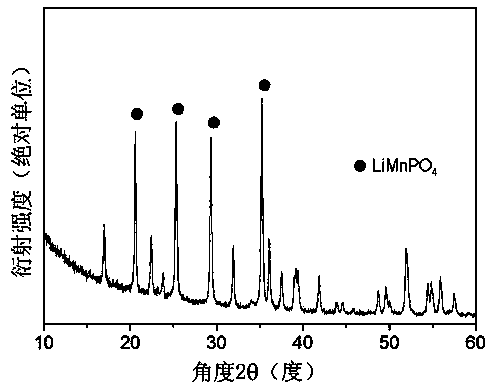

[0035] The Shimadzu XRD-6000 X-ray powder diffractometer (XRD) was used to characterize the lithium manganese phosphate material prepared in Example 1, and the results are as f...

Embodiment 2

[0038] First weigh 126.8g of phosphoric acid (85%), 115g of manganese carbonate, 25g of glucose and 15g of Triton, and disperse the above raw materials in 1160g of deionized water; then add the above suspension to the autoclave The reaction temperature is 140°C, and the reaction time is 5 hours. After the reaction, the filter cake is filtered and washed, and the filter cake is dried at 120°C for 2 hours to obtain the prismatic manganese phosphate precursor; The precursor powder was fully mixed with 48 g of lithium hydroxide, and then sintered at a high temperature for 5 hours under the protection of a nitrogen atmosphere at a sintering temperature of 600° C., and finally cooled naturally to obtain a square lithium manganese phosphate cathode material.

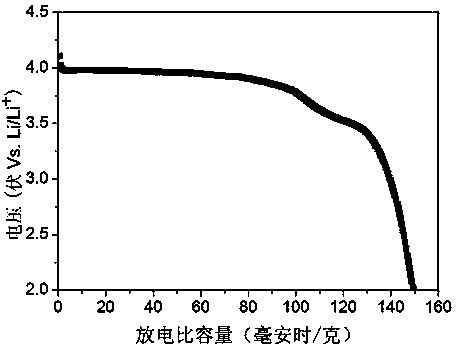

[0039] The XRD and SEM spectra of the lithium manganese phosphate cathode material of Example 2 are the same as those of Example 1, and they are square particles with a particle size of 0.5 μm-1 μm. The electrochemical performance...

Embodiment 3

[0041] First weigh 132.5g of diammonium hydrogen phosphate, 173g of manganese acetate, 45g of glucose and 35g of cetyltrimethylammonium bromide, and disperse the above raw materials in 500g of deionized water; then suspend the above The liquid is added to the autoclave for hydrothermal reaction. The reaction temperature is 240°C and the reaction time is 15 hours. After the reaction, the filter cake is filtered and washed, and the filter cake is dried at 100°C for 5 hours to obtain square phosphoric acid. Manganese precursor; then the precursor powder and 68g of lithium carbonate are fully mixed, and then sintered at a high temperature for 8 hours under the protection of a nitrogen atmosphere at a sintering temperature of 700°C, and finally cooled naturally to obtain a square lithium manganese phosphate cathode material.

[0042] The XRD and SEM spectra of the lithium manganese phosphate cathode material of Example 3 are the same as those of Example 1, and they are square particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com