Preparation of polyphenol oxidase biosensor and detection of polyphenol oxidase biosensor to pesticide residues

A polyphenol oxidase and sensor technology, which is applied to the determination/inspection of microorganisms, biochemical equipment and methods, and instruments, etc., can solve the problems of analysts' operating level requirements, cumbersome processing methods, long analysis cycles, etc. Catalytic efficiency, low price, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

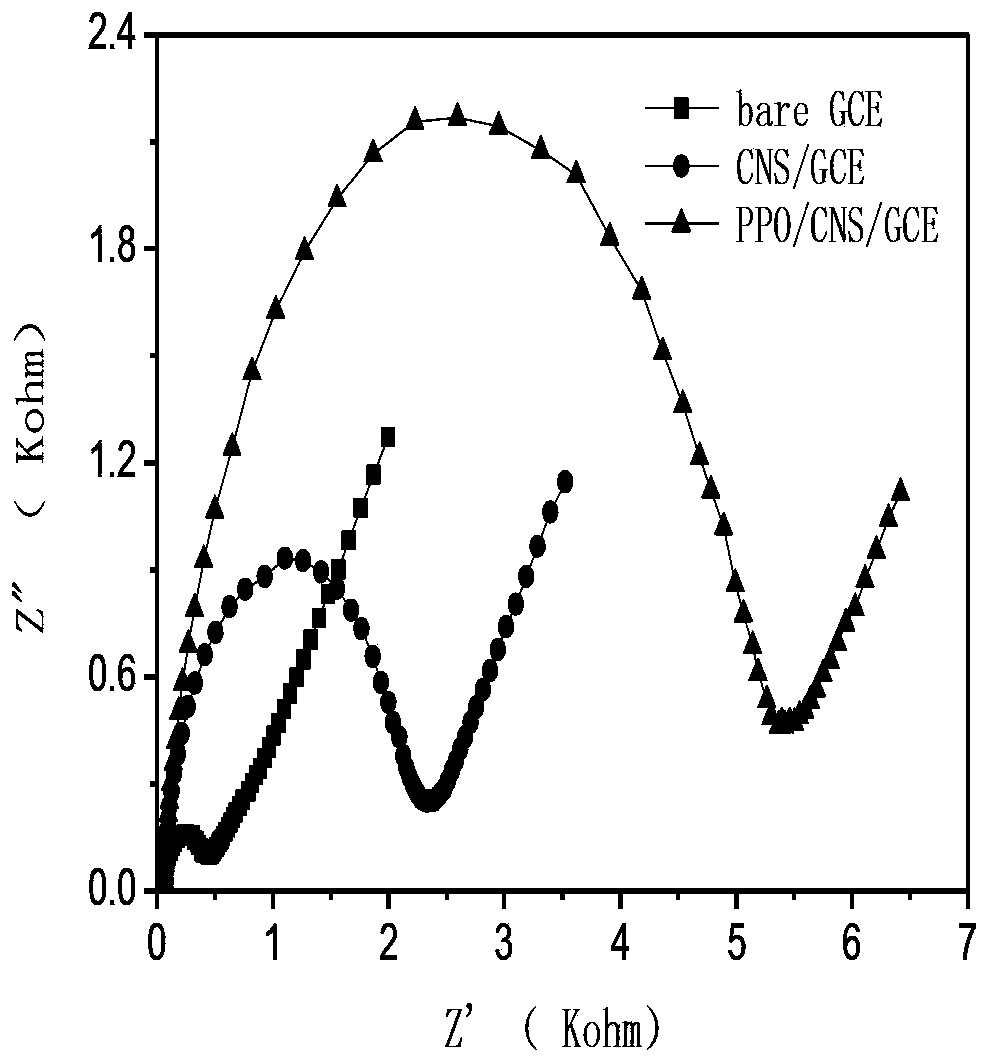

[0040] The present invention is based on the polyphenol oxidase sensor of polyphenol oxidase modified electrode embedded in carbon nanospheres, the sensor comprises a glassy carbon electrode, the detection end of the glassy carbon electrode is surface-modified with carbon nanospheres and polyphenol oxidase, fumigated in a glutaraldehyde atmosphere The enzyme is firmly fixed on the surface of the glassy carbon electrode.

[0041] The preparation method of the polyphenol oxidase biosensor based on the polyphenol oxidase modified electrode embedded in carbon nanospheres in this embodiment comprises the following steps:

[0042] 1. Preparation of carbon nanospheres: Weigh 6g of glucose with an electronic balance and put it into the lining of a 50ml reaction kettle, accurately pipette 35ml of deionized water into the above reaction kettle, and stir the solution with a glass rod to make the glucose completely Dissolve it, then put it into the reactor, tighten the reactor with a wren...

Embodiment 2

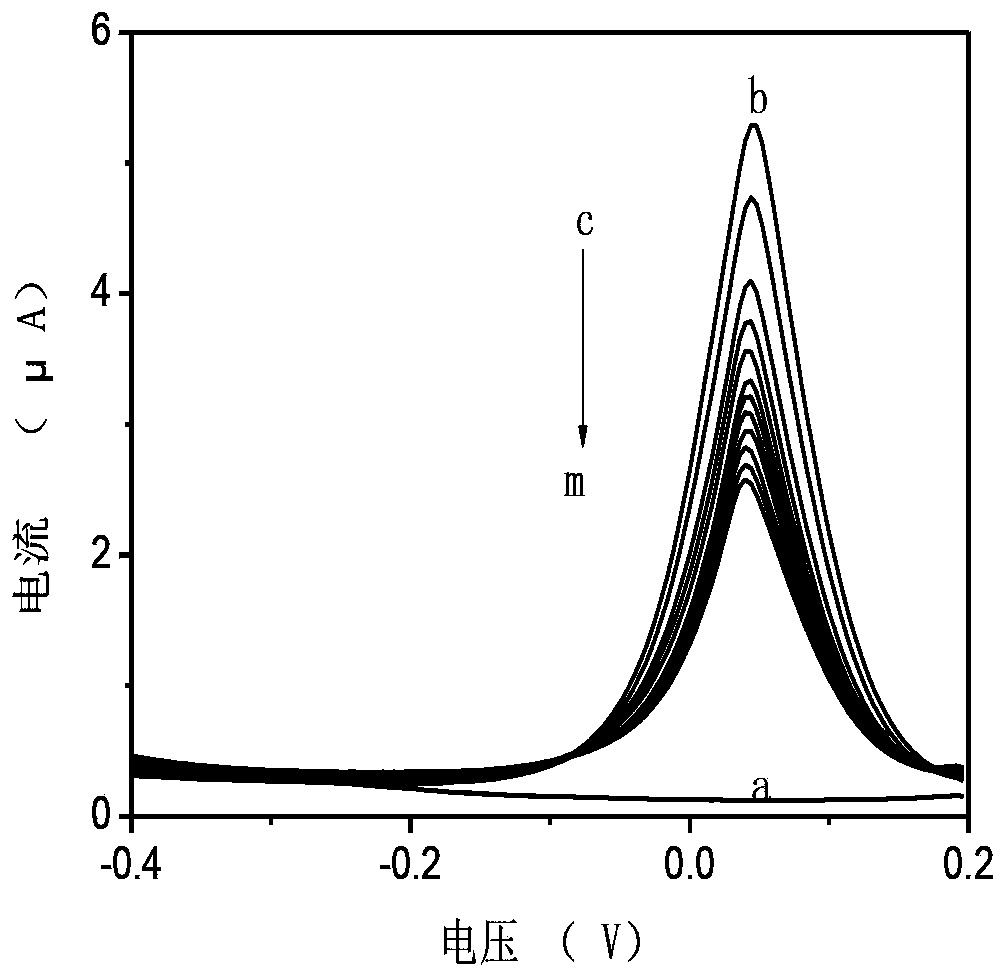

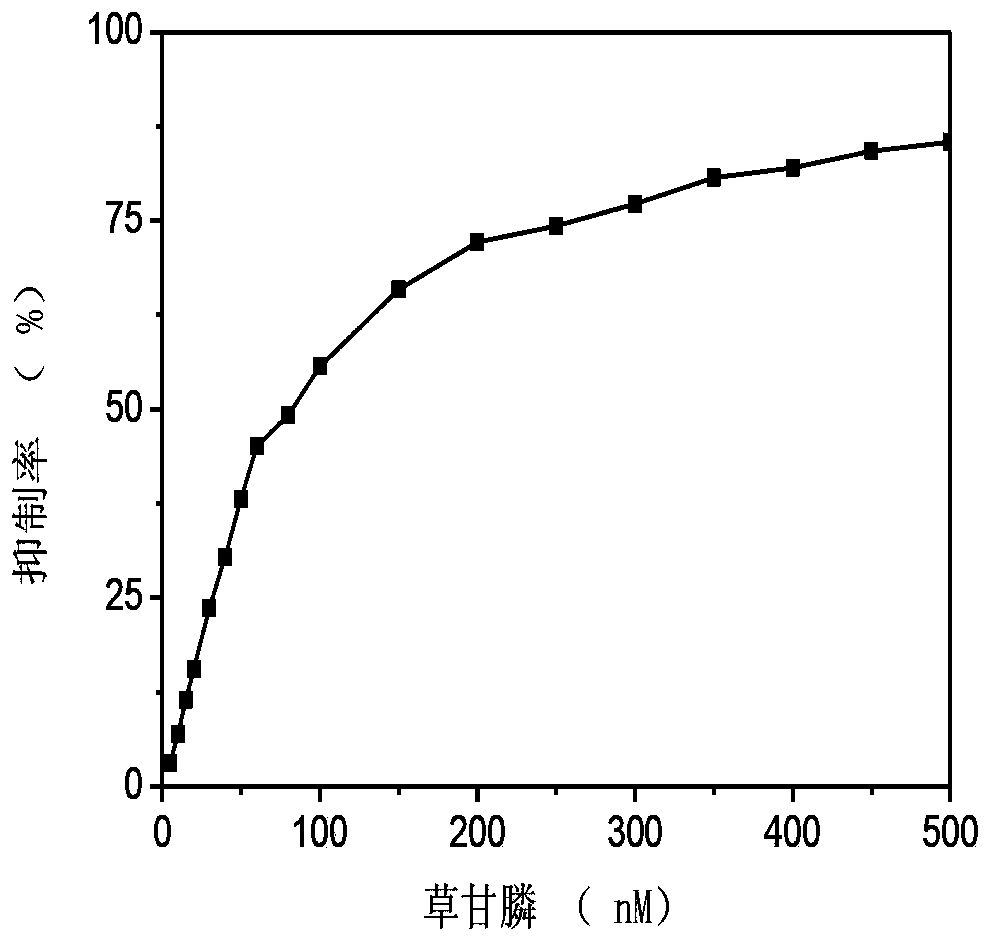

[0055] Detection of Pesticide Residues by Polyphenol Oxidase Biosensor

[0056] The polyphenol oxidase sensor of Example 1 of the present invention is used as the working electrode, the platinum wire electrode is used as the counter electrode, and the saturated dry mercury electrode is used as the reference electrode, and a three-electrode system is established, and the three-electrode system is connected to an electrochemical workstation to detect glyphosate content.

[0057] Working conditions: the buffer used is 0.1M phosphate buffer solution (PBS), and the current response value of the sensor to the same concentration of catechol solution in the range of pH 5.0-8.0. Selected pH = 6.0 as the best value. Under this condition, the current value is large and stable.

[0058] Inhibition time: the polyphenol oxidase sensor is immersed in glyphosate solution and incubated for a period of time, and the enzyme activity is inhibited. The size of the inhibition rate is related to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com