Boron-containing steel production method for reducing steel ladle lining refractory consumption

A production method and ladle technology, applied in the manufacture of converters, etc., can solve problems such as increased smelting costs, high loss of ladle refractory materials, and molten steel oxidation, and achieve the effects of reducing comprehensive smelting costs, reducing erosion, and reducing gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

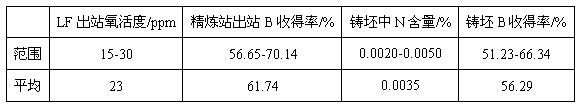

[0031] The nominal capacity of the converter is 50t, and the smelted steel is gas-shielded welding wire, steel grade ER70S-6, H11Mn2SiA, B: 0.0008~0.0030%.

[0032]Addition of deoxidizer for converter tapping: Si-Al-Ba, 0.5-1.5kg / t steel. LF furnace enters the station a[O]=30-50ppm. During the LF refining process, the amount of aluminum particles added is 0.2-0.5kg / t steel; the amount of submerged arc slag added is 1.0kg / t steel. At the end of refining, a[O]=20-30ppm, 10-12kg / heat of boron-iron alloy is added before soft blowing, the flow rate of argon gas for soft blowing is 100-200L / min, and the time of soft blowing is 8min.

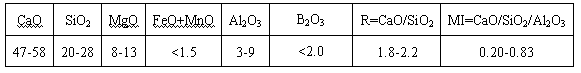

[0033] Table 3 Composition of welding wire steel refining slag / %

[0034]

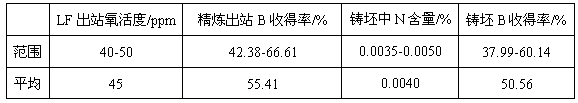

[0035] Table 4 Boron yield of welding wire steel

[0036]

[0037] The boron yield is calculated as 55%, which is about 10% higher than the average yield of the steel with the same activity oxygen condition, and the consumption of boron-iron alloy per heat is reduced b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com