Method for synthesizing copper-zinc-tin-sulfur quantum dots by utilizing ultrasonic cavitation

A nano-quantum dot, copper-zinc-tin-sulfur technology, applied in nanotechnology, nano-optics, nanotechnology, etc., can solve the problems of large-scale use limitation, complex process, and no nano-quantum dots have been seen yet, and the particle size can be achieved. Controlled, environmentally friendly, highly reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

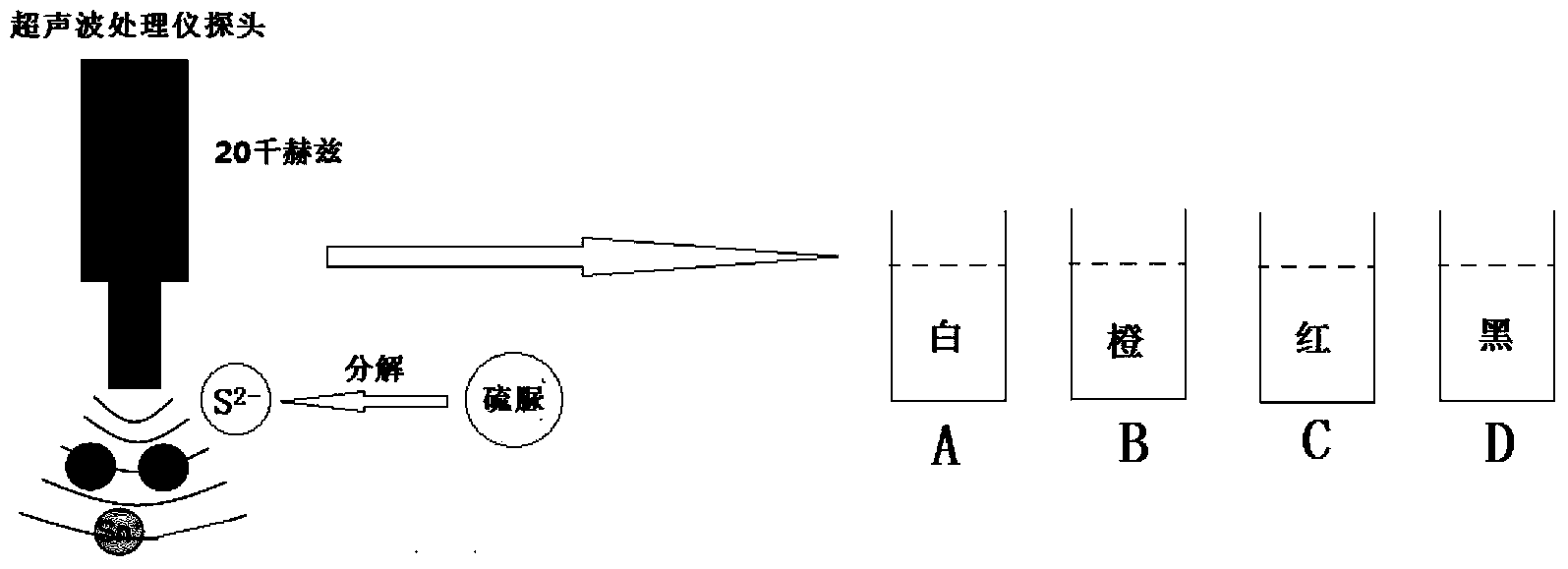

[0031] Step 1, will analyze pure 0.4 millimolar copper sulfate pentahydrate crystals, 0.2 millimoles zinc sulfate heptahydrate crystals, 0.2 millimoles tin sulfate dihydrate crystals and 0.8 millimoles thiourea (CH 4 N 2 S) crystal joins in the ethylene glycol of 20 milliliters of analytical purity, makes the solution that the molar concentration that takes zinc sulfate as standard is 10 mmol / liter, and solution is milky white, is named solution A.

[0032] Step 2. The solution A was separated with a centrifuge (the centrifuge rotated at 4000 rpm and turned on for 3 minutes) to obtain a white powder. With analytically pure n-dodecylmercaptan (CH 3 (CH 2 )10CH 2 SH) Wash the powder repeatedly 6 times.

[0033] Step 6, after washing, a copper-zinc-tin-sulfur nano-quantum dot solution (n-dodecyl mercaptan is used as a solvent) can be obtained.

Embodiment 2

[0035] Step 1, will analyze 0.2 millimolar copper sulfate pentahydrate crystals of purity, 0.1 millimoles zinc sulfate heptahydrate crystals, 0.1 millimoles tin sulfate dihydrate crystals and 0.4 millimoles thiourea (CH 4 N 2 S) crystal joins in the ethylene glycol of 30 milliliters of analytical purity, makes the solution that the molar concentration that takes zinc sulfate as standard is 5 mmol / liter, and solution is milky white, is named solution A.

[0036] Step 2, put the solution A prepared in step 1 into a 50 ml flask, and place the flask on the table of the laboratory ultrasonic processor. Adjust the height of the ultrasonic processor probe so that the probe is submerged 2 cm below the liquid surface.

[0037] Step 3. Set the power of the ultrasonic processor to 300 watts and the frequency to 10 kHz, and turn on the ultrasonic processor for 2 minutes to obtain solution B.

[0038] Step 4. Separate the solution B with a centrifuge (the centrifuge rotates at a speed of 2...

Embodiment 3

[0041] Step 1, will analyze pure 0.4 millimolar copper sulfate pentahydrate crystals, 0.2 millimoles zinc sulfate heptahydrate crystals, 0.2 millimoles tin sulfate dihydrate crystals and 0.8 millimoles thiourea (CH 4 N 2 S) crystal joins in the ethylene glycol of 15 milliliters of analytical purity, makes the solution that the molar concentration that takes zinc sulfate as standard is 10 mmol / liter, and solution is milky white, is named solution A.

[0042] Step 2, put the solution A prepared in step 1 into a 50 ml flask, and place the flask on the table of the laboratory ultrasonic processor. Adjust the height of the ultrasonic processor probe so that the probe is immersed 4 cm below the liquid surface.

[0043] Step 3. Set the power of the ultrasonic processor to 100 watts and the frequency to 30 kHz, and turn on the ultrasonic processor for 6 minutes to obtain solution C.

[0044] Step 4. The solution C was separated with a centrifuge (the centrifuge rotated at 4500 rpm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com