S. cerevisiae strain for producing citicoline through bioconversion and application of S. cerevisiae strain

A technology of Saccharomyces cerevisiae strains and microbial strains, which is applied in the field of biomedicine and can solve problems such as complex processes, low conversion rates, and unstable conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

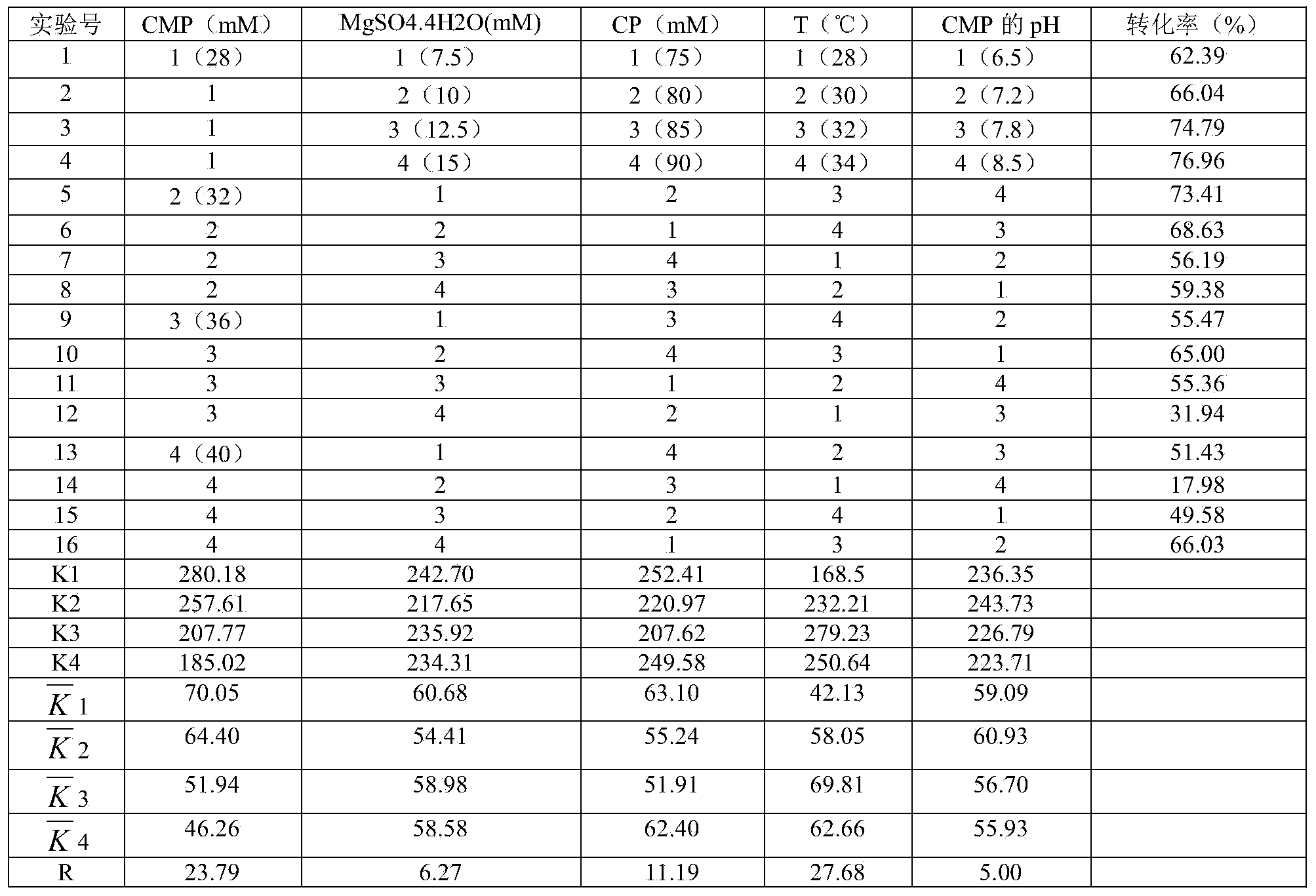

Method used

Image

Examples

Embodiment 1

[0026] Screening of Saccharomyces cerevisiae strains with high activity CMP kinase and high activity phosphorylcholine cytidylyltransferase

[0027] 1. Strains

[0028] Saccharomyces cerevisiae (S.cerevisiae QY131, strain preservation number CGMCC7978) was obtained from CGMCC2842 after mutagenesis.

[0029] 2. Medium

[0030] (1) Original medium A: 3% glucose, 0.3% beef extract, 0.3% yeast extract, 0.5% urea, FeSO 4 ·7H 2 O0.01%, agar 2.5%.

[0031] (2) Medium B for KCl sensitive strain screening: add 1.5mol / L KCl to medium A.

[0032] 3. Strain mutagenesis screening method

[0033] Dissolve diethyl sulfate (DES) stock solution with a small amount of alcohol, prepare 1% DES solution with pH 7.0 phosphate buffer solution, take 2ml of fresh bacterial solution and 2ml of 1% DES, mix well, shake in the dark at 30°C, 200rpm, respectively After treatment for 10, 20, 30, 40, 60, and 80 minutes, add 2ml of 1% sodium thiosulfate to terminate the reaction, serially dilute four tim...

Embodiment 2

[0036] Cultivation of QY131 Yeast

[0037] The slant medium is malt juice agar medium, and the shake flask medium formula is molasses 30g / L, glucose 10g / L, magnesium sulfate 1.2g / L, ammonium sulfate 1.2g / L, urea 0.2g / L, potassium dihydrogen phosphate 1.2g / L, zinc sulfate 0.2g / L, add water to dissolve, adjust the pH to 5.4 (±0.1), and finally adjust the volume to 1L. Use an inoculation needle to pick a ring of slant strains and insert it into a 500ml shake flask containing 100ml of medium, at 28°C, with a rotation speed of 250rpm, and shake it for 16 hours, then insert it into 2000ml of medium (the formula is the same as that of the shake flask medium) ) in a 5L automatic fermenter with a temperature of 28°C, a stirring speed of 300rpm, and an air volume of 0.5vvm for 20 hours. Then it is centrifuged to collect the bacteria, and the bacteria can be used for CMP and phosphorylcholine biotransformation of citicoline after the bacteria are air-dried or quick-frozen to break the w...

Embodiment 3

[0039] Biotransformation of Citicoline in Shake Flasks

[0040] Add 100mL reaction solution into 250ml shake flask, which contains CMP25mmol / L, phosphate buffer 200mmol / L, glucose 4g, phosphorylcholine 5g, magnesium sulfate 0.4g, QY131 yeast 5g (dry weight). 32°C, rotation speed 150rpm, shaking reaction for 6-8h. Feed 2g of glucose every 2 hours, depending on the reaction situation, consider adding sugar 2-3 times, and measure the conversion rate every 2 hours. After reacting for 6 hours under the above conditions, the conversion rate of citicoline can reach 83%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com