Combined treatment method for sodium chloride-containing wastewater generated in dressing and smelting of rare earth

A treatment method and sodium chloride technology, which are applied in the fields of environmental engineering and chemical engineering, can solve the problems of low economic value of sodium chloride salt, unsuitability of sodium chloride-containing wastewater, and high operation cost of wastewater treatment, and achieve easy unorganized discharge. Control, no ammonia and carbon dioxide leakage, cost offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

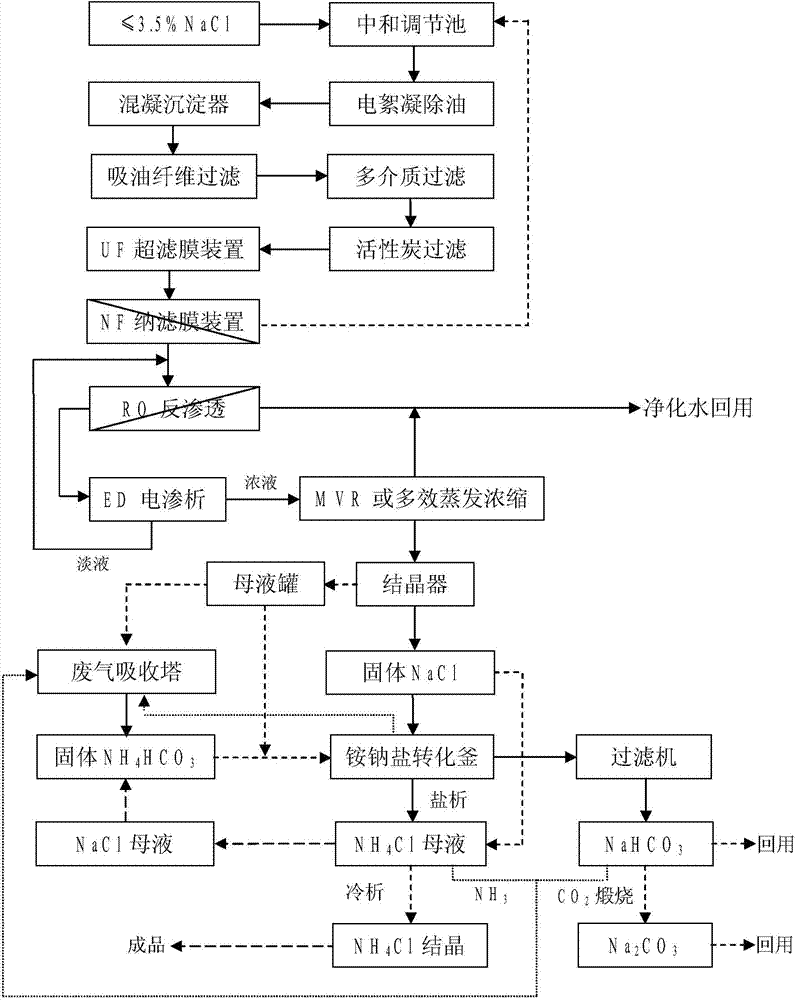

[0031] Discharge the NaCl wastewater with a concentration of 3.5% into the wastewater adjustment tank, and after oil separation, homogenization, aeration, and pH adjustment in the adjustment tank, continue to process in the following order (such as figure 2 shown):

[0032] a. Carry out electrocoagulation demulsification, air flotation and oil removal treatment to remove oily substances, calcium and magnesium ions and sulfate radical precipitation in wastewater;

[0033] b. Wastewater enters the coagulation sedimentation tank, and sodium carbonate and polyacrylamide flocculants are added to the wastewater to further precipitate and separate calcium and magnesium ions and other solid substances in the wastewater;

[0034] c. Adsorption and filtration are carried out through the oil-absorbing fiber filter --- multi-media filter --- activated carbon filter device;

[0035] d. UF ultrafiltration membrane treatment to remove insoluble tiny particles in wastewater;

[0036] e. Us...

Embodiment 2

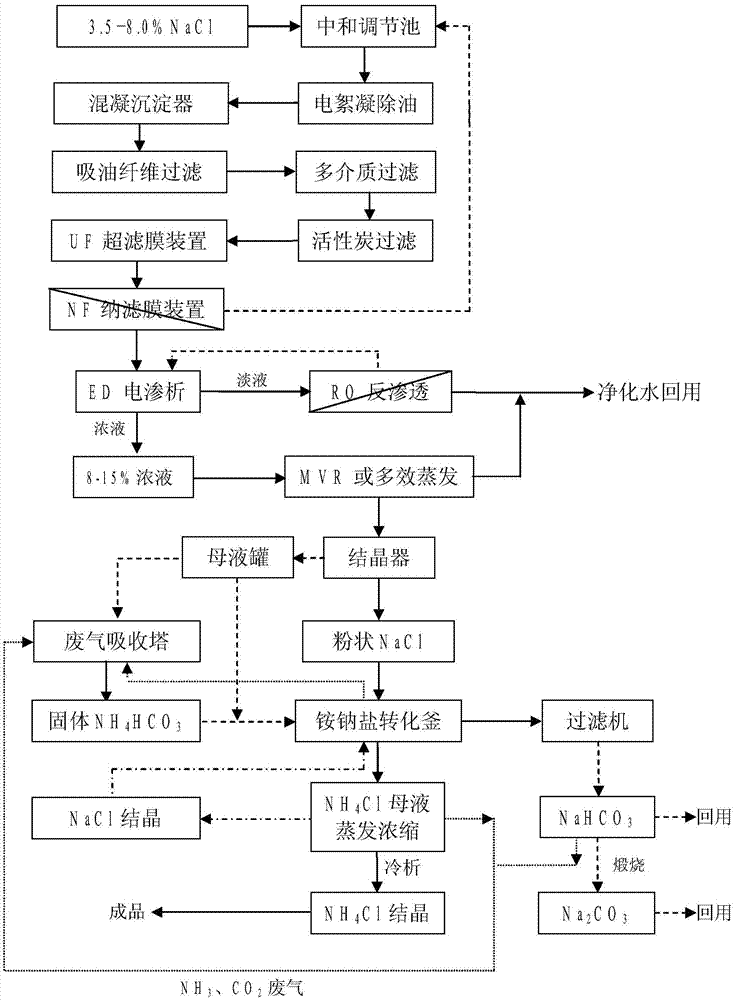

[0044] Discharge the NaCl-containing salty wastewater with a concentration of 5.5% into a separate wastewater adjustment tank, and carry out oil separation, homogenization, aeration, and pH adjustment in the adjustment tank, and then proceed in the following order (such as image 3 shown):

[0045] a. Carry out electrocoagulation demulsification, air flotation and oil removal treatment to remove oily substances, calcium and magnesium ions and sulfate radical precipitation in wastewater;

[0046] b. Wastewater enters the coagulation sedimentation tank, and sodium carbonate and polyacrylamide flocculants are added to the wastewater to further precipitate and separate calcium and magnesium ions and other solid substances in the wastewater;

[0047] c. Adsorption and filtration are carried out through the oil-absorbing fiber filter --- multi-media filter --- activated carbon filter device;

[0048] d. UF ultrafiltration membrane treatment to remove insoluble tiny particles in was...

Embodiment 3

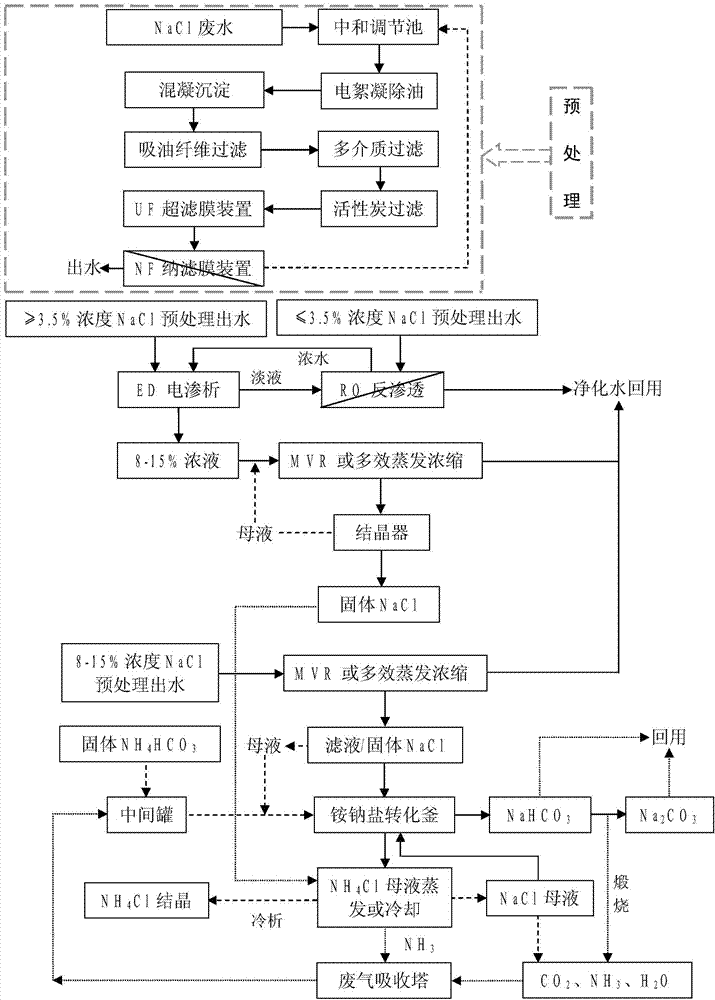

[0058] Discharge the 15% concentration of NaCl-containing saline wastewater into the separately set wastewater adjustment tank, and carry out oil separation, homogenization, aeration, pH adjustment and dosing treatment in the adjustment tank, and then proceed in the following order (such as Figure 4 shown):

[0059] a. Carry out electrocoagulation demulsification, air flotation and oil removal treatment to remove oily substances, calcium and magnesium ions and sulfate radical precipitation in wastewater;

[0060] b. Wastewater enters the coagulation sedimentation tank, and sodium carbonate and polyacrylamide flocculants are added to the wastewater to further precipitate and separate calcium and magnesium ions and other solid substances in the wastewater;

[0061] c. Adsorption and filtration are carried out through the oil-absorbing fiber filter --- multi-media filter --- activated carbon filter device;

[0062] d. UF ultrafiltration membrane treatment to remove insoluble ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com