Resourcable volatile organic tail gas treating method and skid-mounted moving device

A volatile organic and tail gas treatment technology, applied in the field of soil remediation, can solve the problems of waste of energy consumption, complex activated carbon treatment, limited adsorption capacity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

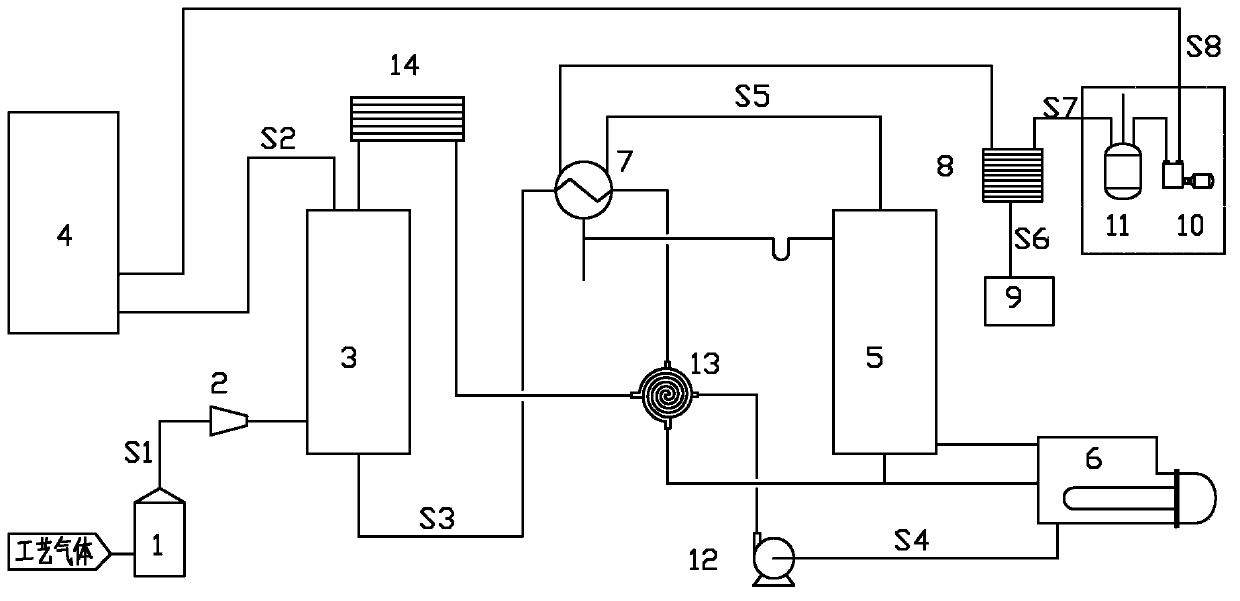

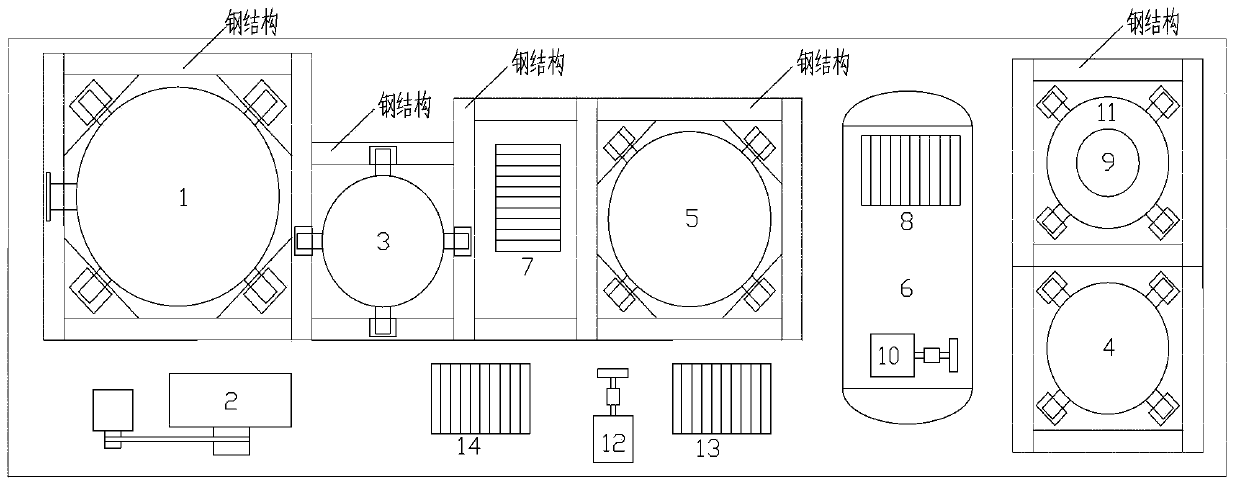

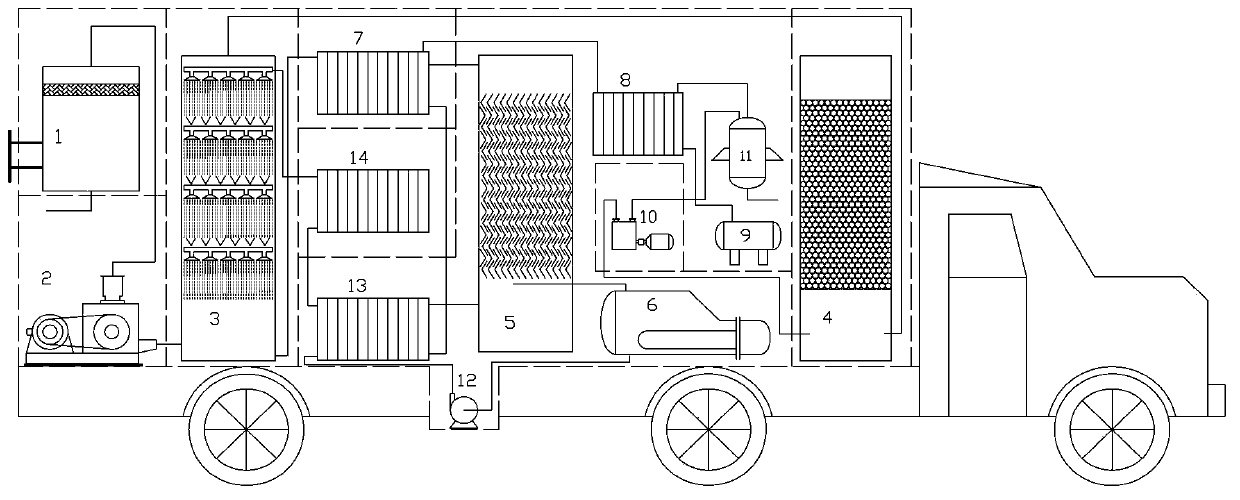

Method used

Image

Examples

Embodiment 1

[0033] To treat a high-concentration tail gas containing pollutants benzene, toluene, and p-xylene, the gas flow rate is 90ml / min, and the triethylene glycol reagent containing less than 5% impurities is used for spraying treatment. The temperature of the spray chamber is 25°C, operated under normal pressure, and the process results obtained after spraying are shown in Table 3:

[0034] Table 2 process results

[0035]

Embodiment 2

[0037] The concentration of pollutants in the tail gas extracted by the gas phase extraction device is about 1.5%, and the extraction flow rate is 500m 3 / h. According to the operating conditions, the temperature of the spray chamber is 30°C, the absolute pressure is 500Kpa, and the size is 400mm×600mm×4000mm; the temperature of the separation chamber is 80~210°C, the absolute pressure is 6Kpa, the size is 600mm×800mm×3500mm; the temperature of the adsorption chamber is 30°C, pressure 110Kpa, size 400mm×400mm×3500mm; condenser temperature 80°C, cryocooler temperature -60°C, spray agent cooling temperature 30°C. Process obtains result as following table 2:

[0038] Table 3 process results

[0039]

[0040] The content of organic pollutants in the gas before treatment is 11.4kg / h, and the recovered organic matter after system treatment is 11kg / h, and the recovery rate of pollutants is 96.5%.

Embodiment 3

[0042] To deal with heavy component pollutants from benzene processing, the concentration of pollutants in the tail gas extracted by the gas phase extraction device is about 0.8%, and the extraction flow rate is 500m 3 / h. According to the operating conditions, the temperature of the spray chamber is 30°C, the absolute pressure is 200Kpa, and the size is 500mm×600mm×4000mm; the temperature of the separation chamber is 80~206°C, the absolute pressure is 6Kpa, the size is 600mm×800mm×3500mm; the temperature of the adsorption chamber is 20°C, pressure 110Kpa, size 400mm×400mm×3500mm; condenser temperature 80°C, cryocooler temperature -20°C, spray agent cooling temperature 30°C. Process obtains result as following table 2:

[0043] Table 4 process results

[0044]

[0045]

[0046] The content of organic pollutants in the gas before treatment is 6.5kg / h, and the recovered organic matter after system treatment is 6.21kg / h, and the recovery rate of pollutants is 95.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com