Preparation method for cadmium hydroxide nano-array capable of adsorbing and extracting DNA

A cadmium hydroxide and nano-array technology, which is applied in the field of preparation of cadmium hydroxide nano-arrays, can solve problems such as limited recycling and unstable nanostructures, and achieve the effects of low cost, stable chemical properties, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Take a piece of pure copper and ultrasonically clean the copper with acetone and ethanol;

[0025] Step 2: Mix 20mL of benzene and 20mL of ammonia solution with pH=11.0 in a beaker, and put the cleaned copper piece into the mixture;

[0026] The third step: slowly drop 3.0mL, 1mol / L cadmium nitrate solution into the beaker;

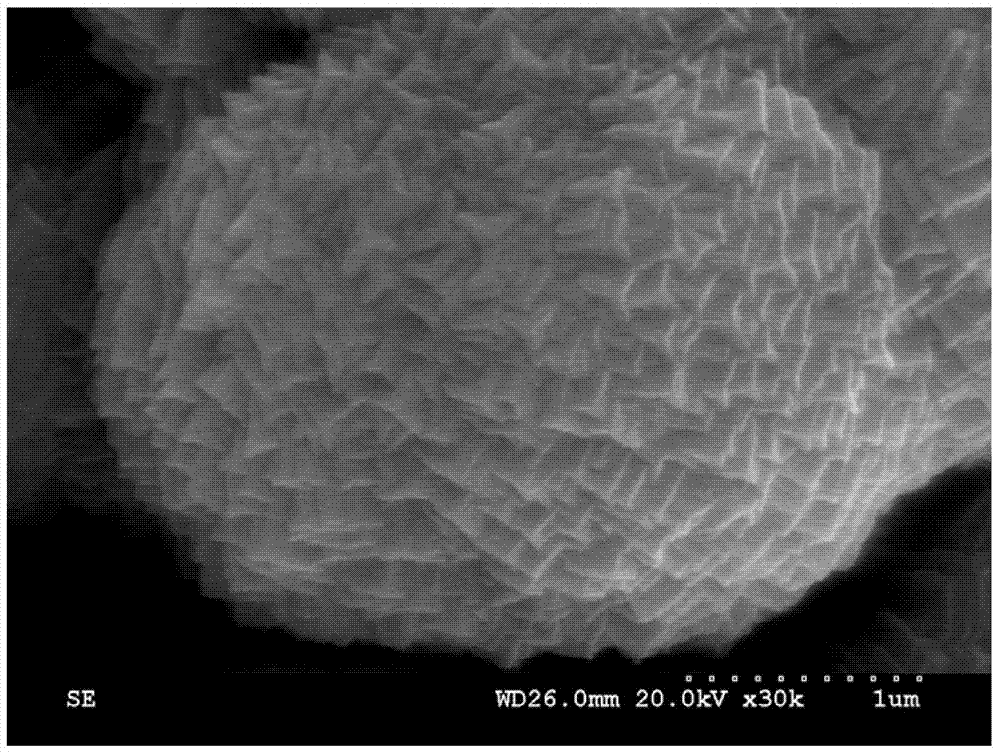

[0027] Step 4: After the dropwise addition, put the beaker into the fume hood. After reacting at room temperature for 24 hours, take out the copper sheet, wash it with distilled water and absolute ethanol several times, and dry it in the air. There is a layer of copper on the surface. The white substance, that is, the cadmium hydroxide nano-array.

Embodiment 2

[0029] Step 1: Take a piece of pure zinc, and use acetone and ethanol to ultrasonically clean the copper sheet;

[0030] Step 2: Mix 20mL of benzene and 20mL of ammonia solution with pH=11.0 in a beaker, and put the cleaned zinc flakes into the mixture;

[0031] The third step: slowly drop 3.0mL, 1mol / L cadmium nitrate solution into the beaker;

[0032] Step 4: After the dropwise addition, put the beaker into the fume hood. After reacting at room temperature for 24 hours, take out the zinc sheet, wash it with distilled water and absolute ethanol several times, and dry it in the air. There is a layer on the surface. The white substance, that is, the cadmium hydroxide nano-array.

Embodiment 3

[0034] Step 1: Take a piece of pure nickel and ultrasonically clean the copper with acetone and ethanol;

[0035] Step 2: Mix 20mL of benzene and 20mL of ammonia solution with pH=11.0 in a beaker, and put the cleaned nickel sheet into the mixture;

[0036] The third step: slowly drop 3.0mL, 1mol / L cadmium nitrate solution into the beaker;

[0037] Step 4: After the dropwise addition, put the beaker into the fume hood, react at room temperature for 24 hours, take out the nickel sheet, wash it with distilled water and absolute ethanol several times, and after drying in the air, there is a layer of nickel on the surface. The white substance, that is, the cadmium hydroxide nano-array.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com