A kind of zirconium hydride surface protection method

A technology of zirconium hydride and zirconium oxychloride, which is applied in the direction of solid-state chemical plating, metal material coating process, coating, etc., can solve the problem of unsatisfactory hydrogen blocking effect, achieve good hydrogen blocking effect, and highlight thermal shock resistance The effect of moderate power and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

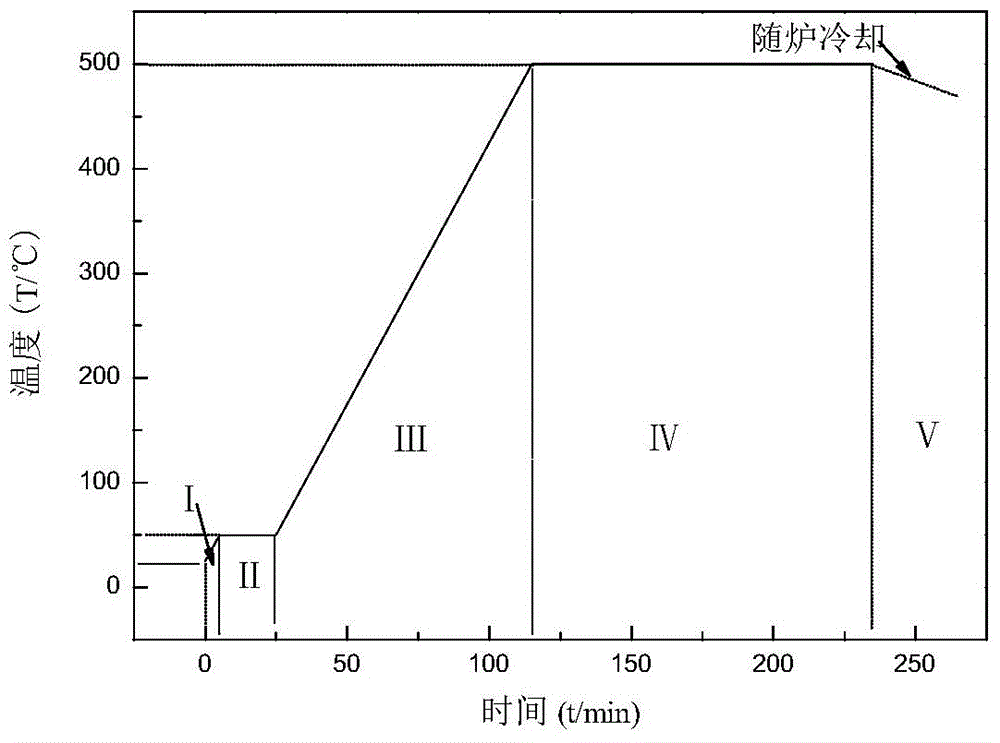

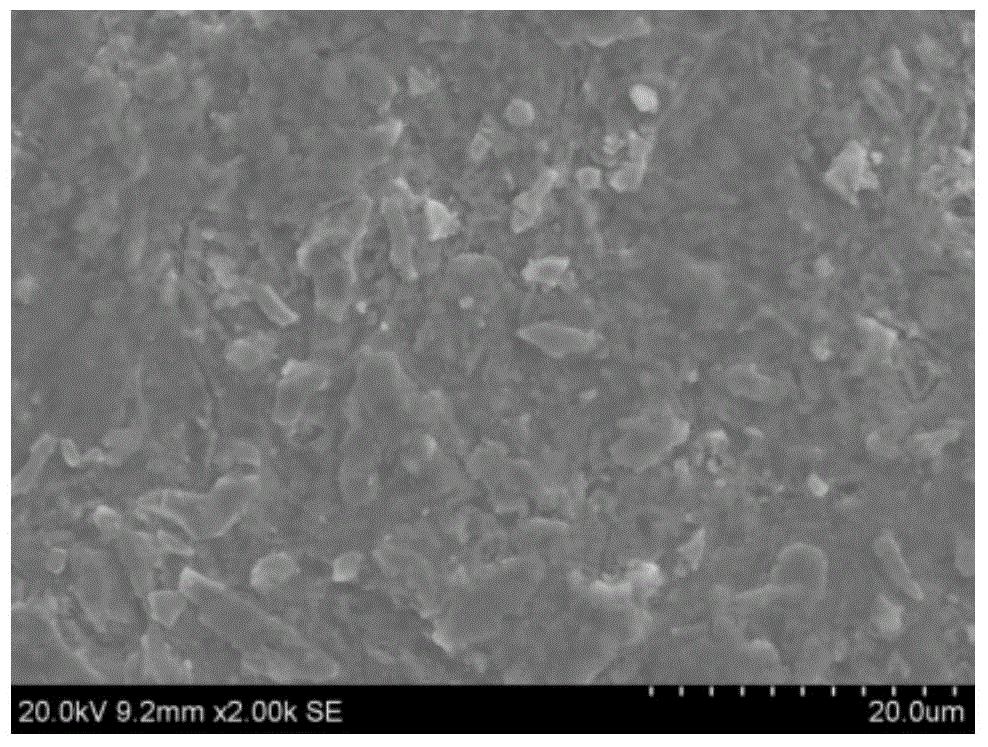

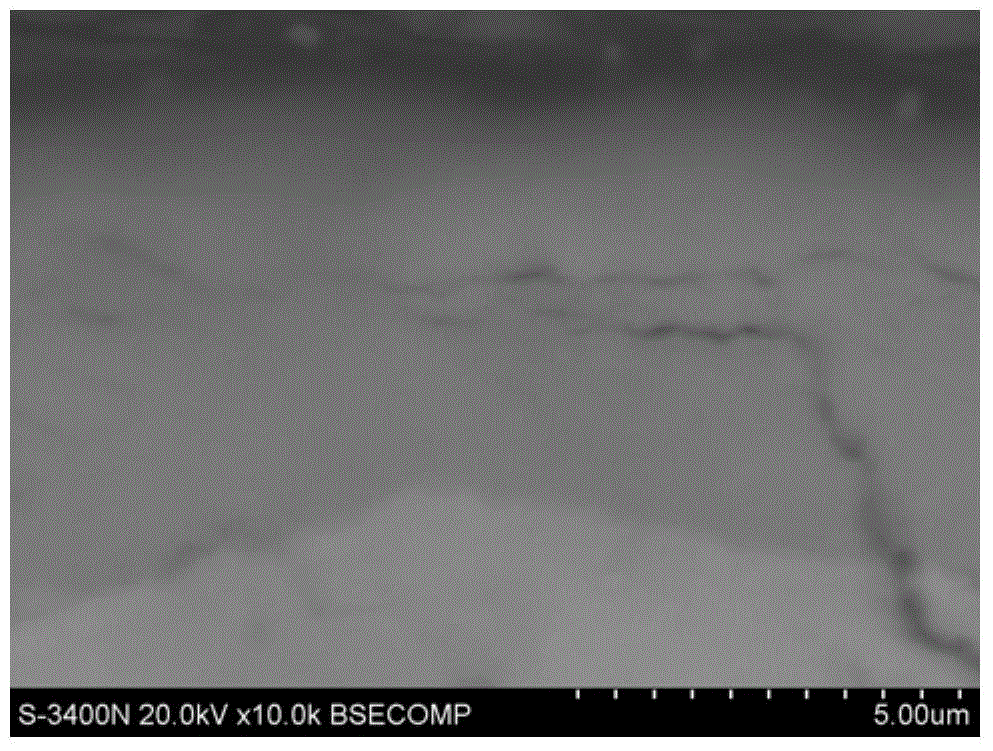

Embodiment 1

[0034] Put zirconium hydride into HF at 5% by volume, HNO 3 45% by volume, H 2 O (the rest is water) polishing solution was etched for 60s, rinsed with deionized water and dried. Put the polished zirconium hydride into a vacuum resistance furnace, vacuumize, and then feed a mixed gas of oxygen (V.5%) and helium (V.95%); Raise to 400°C, keep it warm for 30 hours, then cool to 400°C at a cooling rate of 5°C / min, and then cool to room temperature with the furnace to obtain an in-situ oxide film layer on the surface of zirconium hydride. A mixed solution of distilled water and absolute ethanol is used as a solvent, hydrogen peroxide is used as a catalyst, and zirconium oxychloride is used as a precursor to configure a precursor solution. The composition and content of the precursor solution are: V (absolute ethanol): V (H 2 O)=0.5:1, hydrogen peroxide 50mol / L, zirconium oxychloride 0.1mol / L. Add ammonia water dropwise to the configured precursor solution to adjust the pH value...

Embodiment 2

[0037]Put zirconium hydride into HF at 15% by volume, HNO 3 15% by volume, H 2 O (the rest is water) polishing solution was etched for 15s, rinsed with deionized water and dried. Put the polished zirconium hydride into a vacuum resistance furnace, vacuumize, and then introduce carbon dioxide gas; then raise it from room temperature to 600°C at a rate of 1°C / min, keep it warm for 1 hour, and then increase it at a rate of 1°C / min Cool down to 400°C at a cooling rate, and then cool down to room temperature with the furnace to obtain an in-situ oxide film layer on the surface of zirconium hydride. A mixed solution of distilled water and absolute ethanol is used as a solvent, hydrogen peroxide is used as a catalyst, and zirconium oxychloride is used as a precursor to configure a precursor solution. The composition and content of the precursor solution are: V (absolute ethanol): V (H 2 O)=1:1, hydrogen peroxide 2.5mol / L, zirconium oxychloride 0.1mol / L. Add ammonia water dropwise...

Embodiment 3

[0040] Put zirconium hydride into HF to 10 volume%, HNO 3 30% by volume, H 2 O (the rest is water) polishing solution was etched for 30s, rinsed with deionized water and dried. Put the polished zirconium hydride into a vacuum resistance furnace, vacuumize, and then introduce oxygen; then rise from room temperature to 500°C at a rate of 3°C / min, keep it warm for 20 hours, and then cool down at a rate of 3°C / min Speed cooling to 400°C, and then cooling to room temperature with the furnace, to obtain an in-situ oxide film layer on the surface of zirconium hydride. A mixed solution of distilled water and absolute ethanol is used as a solvent, hydrogen peroxide is used as a catalyst, and zirconium oxychloride is used as a precursor to configure a precursor solution. The composition and content of the precursor solution are: V (absolute ethanol): V (H 2 O)=0.8:1, hydrogen peroxide 30mol / L, zirconium oxychloride 5mol / L. Add ammonia water dropwise to the prepared precursor solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com